Industrial ribbon mixer is based on a U-shaped cylinder and bidirectional spiral ribbons. Through the three-dimensional mixing field of axial convection and radial tumbling, it is made of 304/316L stainless steel or carbon steel, equipped with a patented double spiral ribbon design, achieving 3-15 minutes of rapid mixing, a single machine processing capacity of 0.5-20m³, and a residual rate of <0.3%. The equipment supports heating/cooling functions, and optional PLC intelligent control and data traceability systems.

The patented double spiral ribbon design achieves CV≤5% high uniformity mixing in 3-15 minutes; 304 stainless steel/carbon steel material, corrosion-resistant and easy to clean, is an ideal choice for the chemical industry!

Efficient mixing: 3-15 minutes/batch, uniformity CV≤5%, far exceeding traditional mixers.

Widely adaptable: Whether it is powder materials such as cement, chemical powder, food additives, or granular materials such as feed, fertilizer, and plastic granules, they can meet the diverse production needs of different industries with their unique spiral ribbon structure and mixing principle.

Low energy consumption: 0.4-0.8kWh per ton of material, saving more than 30% energy.

Low residue: large bottom door design, residue rate <0.3%.

Intelligent control (optional): PLC system supports recipe storage and data traceability.

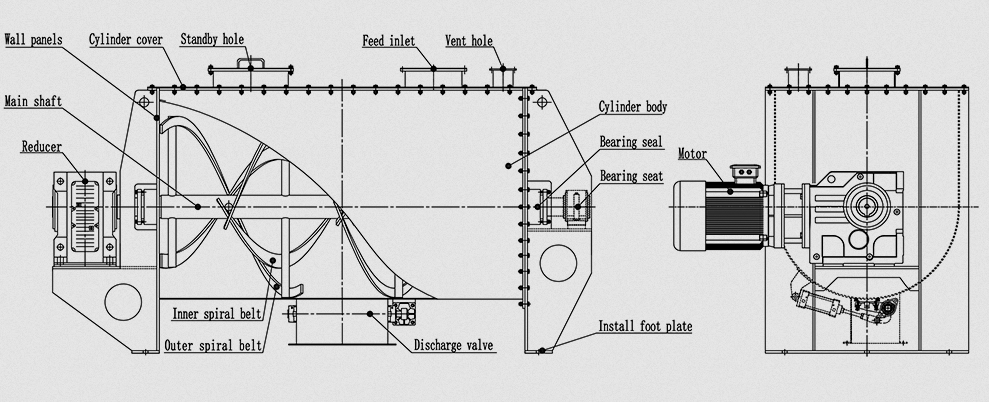

The industrial ribbon mixer is mainly composed of a mixing container, a spiral ribbon, a transmission device and a control system. Its core component, the spiral ribbon, is usually wound around the mixing shaft in a spiral shape to form a certain pitch. According to the geometric shape of the mixing container and the height of the liquid layer, the ribbon mixer can be divided into single ribbon, double ribbon, conical single ribbon, conical double ribbon and other types. Among them, the double ribbon mixer realizes the convection movement of the material during the mixing process through the reverse rotation of the inner and outer layers of the ribbon, thereby improving the mixing effect.

The working principle of the industrial ribbon mixer is based on the material convection and shearing effect generated by the rotation of the ribbon. When the stirring shaft drives the spiral ribbon to rotate, the outer spiral ribbon and the inner spiral ribbon push the material to move in opposite spiral directions. The outer spiral ribbon transports the material from both ends of the cylinder to the middle area, and the inner spiral ribbon transports the material in the middle area to both ends in the opposite direction. This two-way axial pushing action forms a circular convection of the material in the cylinder, so that the material is constantly exchanged and mixed in the axial direction.

According to different application requirements and container shapes, industrial spiral ribbon mixers can be divided into many types.

Single spiral ribbon mixer: suitable for shallow containers, simple structure, easy operation.

Double spiral ribbon mixer: through the double-layer spiral ribbon design, the mixing efficiency and uniformity are improved, suitable for medium and high viscosity materials.

Conical ribbon mixer: suitable for conical containers, can better adapt to the distribution of materials in the container.

Screw mixer: on the basis of the spiral ribbon, the screw structure is added to enhance the axial driving force of the material, suitable for high viscosity or large specific gravity materials.

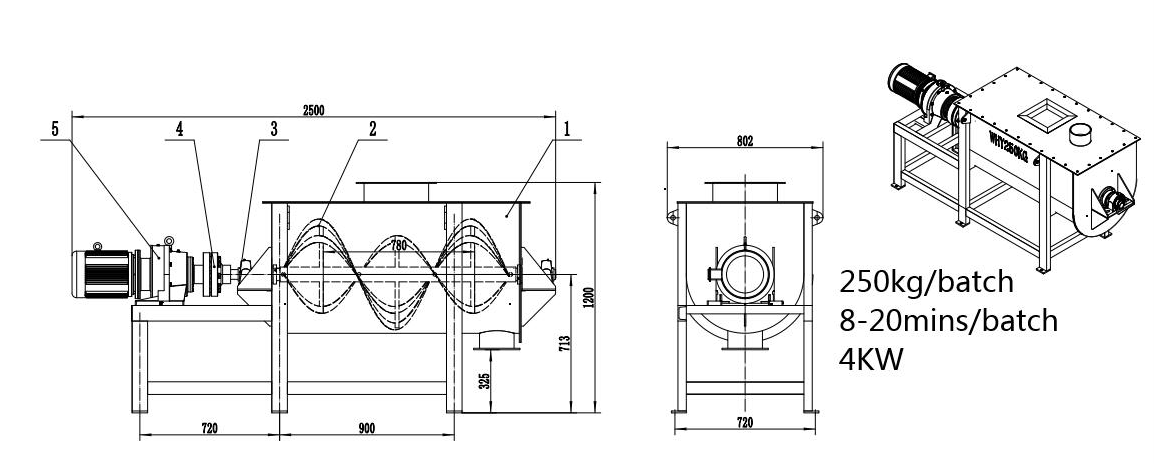

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Industrial ribbon mixers are suitable for mixing a variety of industrial materials. The following are the types of industrial materials that can be mixed using industrial ribbon mixers.

Mixing powders with powders: such as chemical raw materials, food additives, pharmaceutical raw materials, ceramic powders, metal powders, quartz powders, organic fertilizers, plastic particles, pigments, etc. The design of its double or triple spiral ribbons allows the materials to form convection motion during the mixing process, thereby achieving uniform mixing.

Mixing powders with liquids: Add liquid additives or adhesives to the powder to form a uniform paste or slurry.

Paste-like, viscous or high-specific-gravity materials: Especially suitable for mixing paste-like, viscous or high-specific-gravity materials, such as putty, real stone paint, ceramic slurry, PVC slurry, rubber solution, sealant, dye intermediate, fertilizer, etc. Due to the high viscosity or specific gravity difference of these materials, traditional mixing equipment is difficult to achieve uniform mixing, while ribbon mixers can easily cope with them.

As a professional industrial ribbon mixer manufacturer, Dahan Machinery has been focusing on the research and development of a full range of 0.5-20m³ mixing equipment for many years. It uses 304/316L stainless steel or carbon steel (Ra≤0.8μm mirror polishing), equipped with 7.5-75kW variable frequency motor and patented double ribbon design, to achieve high uniformity mixing with CV≤5%, processing capacity of 1-30 tons/hour, and residual rate <0.3%; the product has passed ISO9001/CE certification, supports heating/cooling and PLC intelligent control, and has served 500+ chemical, food, and environmental protection companies around the world, and is a reliable partner in the field of industrial mixing.

The industrial ribbon mixer plays an important role in industrial production with its unique structural design, efficient mixing performance and wide applicability. Through scientific selection and proper maintenance, enterprises can give full play to their advantages, improve production efficiency, ensure product quality, reduce production costs, and lay a solid foundation for the development of enterprises.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.