1000L stainless steel ribbon mixer is a 1000-liter capacity mixing device that utilizes the rotation and pushing action of spiral blades to powerfully mix materials. It features uniform mixing, high efficiency and energy saving, strong adjustability, and easy cleaning. It can evenly mix powdered materials such as flour, rice flour, seasonings, and milk powder, and can also handle pastes containing liquid additives. Made of stainless steel, the equipment has excellent corrosion resistance and hygiene, meeting industry hygiene standards.

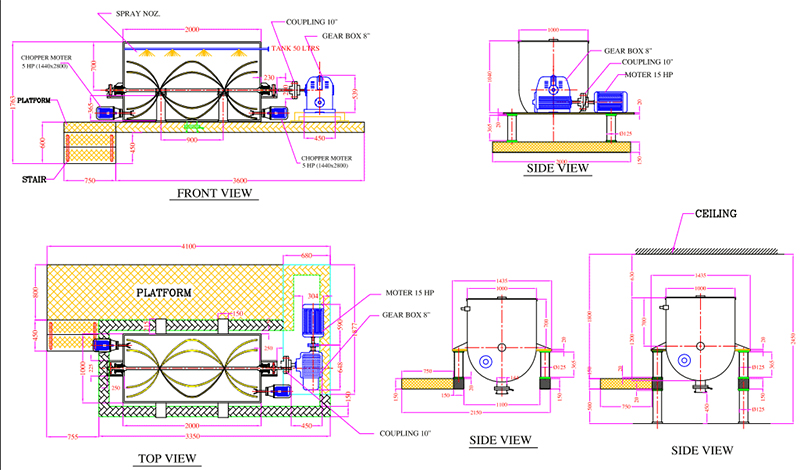

The 1000L stainless steel ribbon mixer supports both horizontal and vertical configurations. The horizontal model uses a classic U-shaped trough design and can be configured with bottom or side discharge ports as needed. Bottom discharge ensures thorough discharge and low residue, while side discharge is suitable for continuous supply requirements in production lines. The vertical model has a compact structure and small footprint, suitable for production scenarios with limited space. Mixing time is only 3-8 minutes, and the material is mixed in a top-down manner.

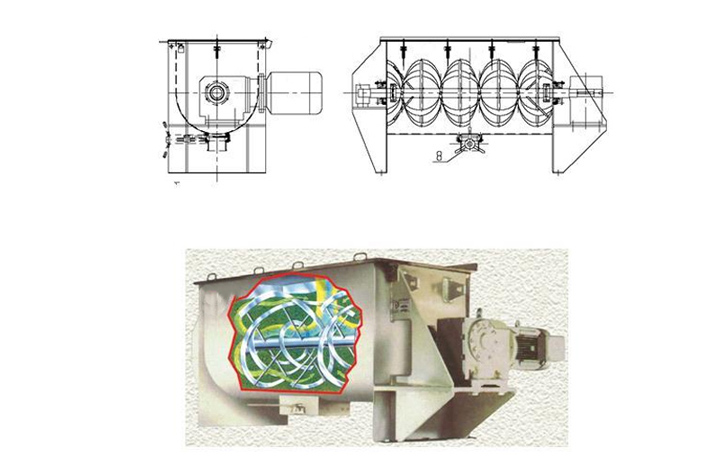

The 1000L stainless steel ribbon mixer achieves uniform mixing through ribbon agitation. After startup, the motor drives the mixing shaft to rotate via a hardened gear reducer, causing the single/double ribbon blades to rotate accordingly. In the double ribbon model, the inner ribbon pushes material from both ends of the tank towards the center, while the outer ribbon pushes material from the center to both ends in the opposite direction, creating axial convection. In the single ribbon model, material is pushed axially, and radial diffusion is achieved through the force of gravity and collision of the particles. During mixing, polypropylene particles and additives are rapidly homogenized in a closed-loop circulation, reaching uniformity in 3-8 minutes. After completion, the material is discharged through the bottom or side outlet, achieving continuous and stable mixing operations.

The 1000L stainless steel ribbon mixer, with its fully enclosed structure and multi-functional configuration, is the preferred equipment for medium-sized mixing scenarios. Constructed from 304/316L stainless steel, its polished inner wall eliminates dead corners, and the fully enclosed design effectively prevents dust leakage and material contamination, ensuring a clean production environment. It supports the addition of a side spray device for precise addition of liquid additives, achieving efficient solid-liquid mixing. The horizontal model offers optional bottom/side discharge ports, ensuring thorough discharge with a residue rate of ≤1%; the double-ribbon stirring structure achieves homogenization in 3-8 minutes. The equipment is compatible with various materials including granules, powder additives, and slurries.

The 1000L stainless steel ribbon mixer consists of a U-shaped cylinder, double or triple-layer spiral ribbon mixing blades, and a transmission component. The forward and reverse rotation of the spiral ribbons creates convection, enabling rapid and uniform mixing of powders, pastes, and viscous materials.

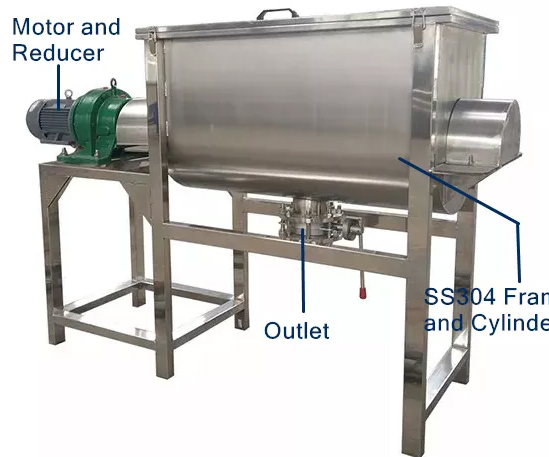

Mixing barrel: Made of high-quality stainless steel material, with a capacity of 1000 liters, it is corrosion-resistant and easy to clean.

Mixing ribbon: It consists of two layers of spiral ribbons, the inner layer pushes the material outward, and the outer layer pushes the material inward, forming a convection cycle to achieve efficient mixing.

Drive system: It is composed of a motor, a reducer, etc., to provide power for the mixing ribbon.

Discharging device: Usually a pneumatic or manual butterfly valve is used to discharge the mixed material conveniently and quickly.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

This 1000L stainless steel ribbon mixer is suitable for medium-capacity mixing scenarios in various fields such as modified plastics, food additives, and chemical powders. It can quickly mix polypropylene granules with masterbatches and glass fibers to meet the needs of injection molding and extrusion processing. Its fully enclosed structure and spray function also make it suitable for precise proportioning of food-grade powders and liquid additives.

Food industry: Stainless steel ribbon mixers are widely used in food processing. It can be used to mix flour, seasonings, food additives, protein powder and other raw materials to ensure the uniformity and stability of the product.

Chemical industry: In chemical production, stainless steel ribbon mixers are used to mix powders, granular materials, liquids and paste materials. It is often used in the manufacture of adhesives, pigments, dyes, plastics, rubber and other products.

Pharmaceutical industry: Stainless steel ribbon mixers play an important role in the pharmaceutical process. It can be used to mix pharmaceutical raw materials such as pharmaceutical powders, preparations, tablets, and capsules to ensure uniform distribution and stability of pharmaceutical ingredients.

Metallurgical industry: In the metallurgical process, stainless steel ribbon mixers can be used to mix metal powders, ores and additives to prepare alloy materials and metallurgical products.

Building materials industry: In building materials production, stainless steel ribbon mixers can be used to mix cement, gypsum, powdery additives and other materials to prepare concrete, mortar, gypsum boards and other products.

The 1000L stainless steel ribbon mixer is designed for high-speed, uniform mixing. It employs a single/double ribbon mixing structure to precisely mix polypropylene granules with masterbatches, fillers, and other materials. It supports side spraying for adding liquid additives, and its fully enclosed design prevents dust and contamination.

Speed: The high mixing speed is about 5-15 minutes.

Material: The ribbon mixer can be made of SUS304 or 316 (such as SUS304 or 316).

Discharge valve: You can also choose discharge valve, butterfly valve, flap valve and gas valve discharge. Capacity range: from 50L-25000L, most of them depend on customer requirements, now the popular selling capacity is 500L, 1000L, 2000L, 5000L.

1000L stainless steel ribbon mixer is a large-capacity mixing equipment widely used in many industries. In order to ensure that you choose the equipment that suits your needs, here are some detailed purchase suggestions

1000L capacity applicable scenario: 1000L capacity is suitable for medium-scale production needs and can meet the requirements of batch mixing. If your production scale is large or you need to mix frequently, 1000L is an ideal choice.

High-quality stainless steel: The mixing chamber, mixing shaft and blades of the mixer should be made of high-quality stainless steel (such as 304 or 316L stainless steel) to ensure corrosion resistance and hygiene standards.

Material properties: Select the appropriate motor power according to the properties of the material (such as density, viscosity, particle size, etc.). For example, mixing viscous materials requires a higher power motor.

Mixing requirements: If fast mixing or processing of high-viscosity materials is required, it is recommended to choose a higher power motor to ensure mixing efficiency.

DaHan Machinery focuses on improving product quality and performance. Through rigorous quality control and inspection, we ensure that every piece of equipment meets high standards and supports customized single-shaft and dual-shaft ribbon structures. The equipment can be equipped with a hydraulic drive mode, significantly improving mixing power and operational stability, achieving efficient and homogeneous mixing in 3-8 minutes. We can tailor-optimize the equipment structure, discharge method, and functional configuration based on customer-provided drawings and production site conditions to meet the production needs of modified plastics, food additives, and other fields. We offer one-stop service from design to manufacturing, winning customer recognition with superior quality and customized solutions.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.