100kg Spice Horizontal Mixer is designed for the food and condiment industry. It is made of food-grade 304 stainless steel. The mixing uniformity is as high as CV≤5%. The single batch processing capacity is 100kg, and the mixing is completed quickly in 3-5 minutes. The equipment adopts a unique spiral belt + paddle dual motion design to ensure that powdered, granular and oil-containing (≤5%) spices are mixed without dead ends, and the residual rate is <0.3%. PLC intelligent control, liquid spray and CIP cleaning system are optional. It is especially suitable for small and medium-sized food companies, central kitchens and spice processing plants. It is an ideal choice for improving production efficiency and product quality!

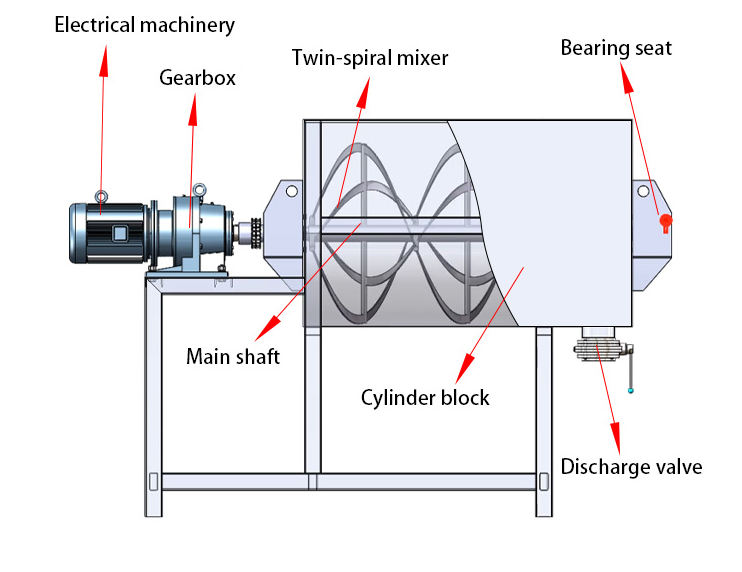

The modular structure supports quick disassembly and cleaning. The core components include drive device, stirring shaft system, intelligent control box, etc., which meet food-grade safety production requirements.

Mixing cylinder: Made of 304 stainless steel, the internal mirror polishing treatment (Ra≤0.8μm) meets food-grade hygiene standards.

Mixing blade: double-layer spiral ribbon design (main shaft + inner spiral) to achieve bidirectional material movement.

Drive system: equipped with 2.2-4kW variable frequency motor, adjustable speed (20-60rpm), adapt to different spice characteristics.

Sealing system: silicone sealing ring + pneumatic locking device to prevent spice volatilization and cross contamination.

Discharging device: large bottom door design (manual/pneumatic optional), discharging time ≤30 seconds, residual rate <0.5%.

Control system: basic type (button control) or intelligent type (PLC touch screen, optional recipe storage function).

The 100 kg horizontal spice mixer achieves high-speed production through a scientific mixing process. After the material is fed from the top, it takes only 3-5 minutes to complete uniform mixing (CV value ≤5%) under the triple effects of axial pushing, shear crushing and throwing diffusion of the mixing paddle, and finally quickly discharges through the bottom pneumatic door (residual rate <0.5%).

In the field of spice mixing, the 100kg horizontal spice mixer has become the core equipment for small and medium-sized production with its precise data advantages.

High uniformity: With a spiral ribbon or paddle stirring structure, the material forms a triple movement of convection, shear and diffusion in the cylinder, ensuring that the spices (such as chili powder, five-spice powder, curry powder, etc.) are mixed evenly within 3-5 minutes.

No dead angle stirring: horizontal structure + full-size stirring blades solve the problem of residue at the bottom of the vertical mixer, and the mixing dead angle is ≤ 0.5%.

Food grade material: The 304 stainless steel inner tank is mirror polished (Ra≤0.8μm) for the part in contact with the material, which meets FDA/CE food hygiene standards, is corrosion-resistant and easy to clean.

Sealed and dustproof: Equipped with silicone sealing ring + pneumatic locking device to prevent the volatilization or cross contamination of spices, especially suitable for highly volatile spices (such as pepper and vanilla powder).

Suitable for a variety of spices: can handle powdered, granular, and compound spices containing trace amounts of oil (≤5%), and can adapt to materials of different densities through variable frequency speed regulation (20-60rpm).

Customized options: optional liquid spray system (adding flavors/oils), anti-static device (for easily adsorbed powders), etc.

PLC touch screen: preset 10-20 groups of formulas, automatically record process parameters, support data export and traceability, and meet certification requirements.

This equipment is designed for food-grade spice mixing and can quickly process powdered, granular and compound spices.

Powdered spice mixing: can mix 80-200 mesh fine powders such as chili powder, pepper powder, and five-spice powder at high speed. Prevent dust by optimizing the speed, and support the addition of anti-caking agents to improve fluidity, ensuring that the mixing uniformity CV value is ≤5%.

Granular spice processing: Suitable for 3-5mm granular raw materials such as coarse black pepper and mustard seeds. It adopts 20-30rpm low-speed stirring with anti-breakage blades to achieve uniform fusion of materials with different densities such as sesame and chili flakes while maintaining the integrity of the particles.

Composite spice integration: For multi-component formulas such as curry powder and barbecue seasoning, the layered feeding technology is used to ensure the precise distribution of trace ingredients, and the liquid spray system can be integrated to add ≤5% oil/flavor to achieve uniform mixing of powder-particle-liquid three phases.

The 100 kg horizontal spice mixer is widely suitable for a variety of 100 kg production scenarios that require spice mixing with its precise mixing performance and moderate processing capacity. From food seasoning to fine chemicals, it can meet the diverse needs of different industries.

Condiment production: The 100 kg horizontal spice mixer can be used to mix five-spice powder, thirteen spices, hot pot base spices, etc. About 100 kg of spices can be processed at a time, such as mixing chili powder, pepper powder, cumin powder, etc. according to the formula, and it only takes 5-8 minutes to achieve a mixing uniformity of more than 98%.

Baked food production: Bakeries and pastry processing factories often use this mixer to mix baking spices. Processing 100 kg of raw materials at a time can fully mix cinnamon powder, vanilla extract, lemon zest, etc. with flour, sugar, and oil.

Snack food seasoning: When producing snack foods such as potato chips and nuts, the 100 kg horizontal spice mixer can evenly coat the seasoning powder on the surface of the food.

Perfume and spice blending: In perfume laboratories or small perfume processing factories, the 100 kg horizontal spice mixer can be used to blend perfume and spices. Processing 100 kg of spice raw materials at a time can evenly mix a variety of spices such as rose essential oil, jasmine essence, sandalwood, etc. Fragrance for toiletries: When producing toiletries such as shampoo and shower gel, this mixer can evenly disperse the fragrance in 100 kg of liquid raw materials.

The price of 100kg horizontal spice mixer fluctuates due to many factors. From the material point of view, the price of ordinary carbon steel is more affordable, which may be around US$2,000; if food-grade 304 stainless steel is used, the price is usually between US$3,000 and US$5,000 due to its strong corrosion resistance and compliance with hygiene standards. In terms of configuration, the basic model only has a simple mixing function and is relatively low in price; the one with frequency conversion speed regulation, intelligent temperature control and other functions can accurately control the mixing process, and the price will rise to US$6,000-8,000. Different brands have different prices due to differences in production processes and market positioning. Products of well-known brands are often US$1,000-2,000 more expensive than ordinary brands because of their guaranteed quality and after-sales service.

The 100kg horizontal spice mixer has become the core equipment for small and medium-sized spice processing companies with its compact structure, high-speed mixing performance and food-grade safety standards. Users can choose different configurations according to production needs, balance investment costs and production efficiency, and achieve stable output of high-quality spice products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.