Animal Nutrition Products Ribbon Mixer is a high-efficiency mixing equipment designed for feed additives, premixes and functional nutrients. It adopts a bidirectional ribbon structure and 304/316L stainless steel. It can achieve uniform mixing with a CV value of ≤5% within 5-15 minutes, and is perfectly suitable for powder, granule and liquid addition. Its gentle low-shear design can protect the activity of heat-sensitive ingredients. With the optional heating/cooling system, it can meet the refined mixing needs of various nutritional products such as vitamins, minerals, and probiotics, with a residual rate of ≤0.1%.

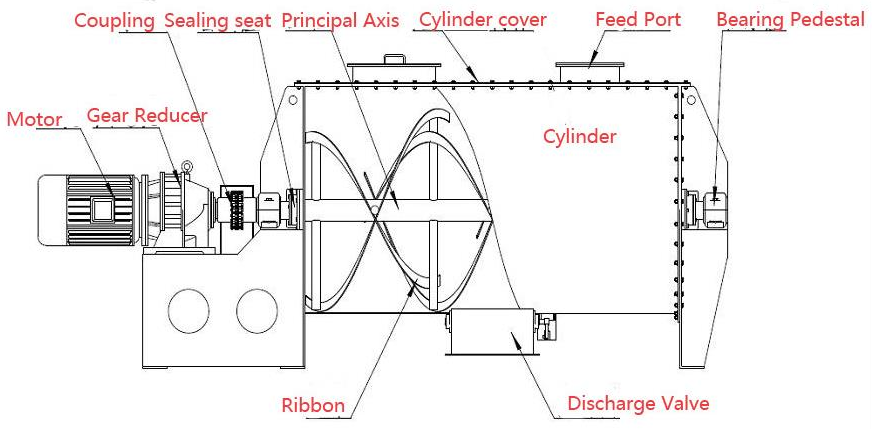

The animal nutrition products ribbon mixer is mainly composed of a U-shaped mixing trough, a ribbon stirring shaft, a transmission device, a feed port and a discharge port.

U-shaped mixing trough: As the core space for material mixing, the U-shaped mixing trough is usually made of high-strength stainless steel with good corrosion resistance and wear resistance.

Spiral stirring shaft: This is a key component of the ribbon mixer. The stirring shaft is equipped with inner and outer layers of ribbons.

Transmission device: The transmission device consists of a motor, a reducer, a coupling, etc.

Feed port and discharge port: The feed port is located above the mixing tank, and different feeding methods can be selected according to the production process and material characteristics.

The ribbon mixer is mainly composed of a horizontal cylinder, a double-layer or multi-layer coiled ribbon agitator, a transmission component and a discharge valve, among which the core is a uniquely designed ribbon agitator. Usually, the agitator consists of two layers of counter-rotating ribbons, the outer ribbon gathers the material from both ends to the middle, and the inner ribbon transports the material from the middle to both ends, achieving all-round and multi-angle convection mixing, thereby quickly and evenly mixing the material.

Food-grade stainless steel is corrosion-resistant and easy to clean, suitable for the production of multiple feeds such as livestock, poultry, and aquatic products. Frequency conversion speed regulation + intelligent control, flexible response to different material characteristics.

High mixing uniformity: The animal nutrition product ribbon mixer can achieve a mixing uniformity of more than 99%. Through the unique ribbon structure design and reasonable mixing process, it can achieve uniform mixing in a short time.

Strong adaptability: The equipment is suitable for various types of animal nutrition materials, including powdered materials (such as corn meal, soybean meal, fish meal, etc.), granular materials (such as premix granules, mineral granules, etc.) and materials containing liquid additives (such as oil, molasses, etc.).

Low residue design: The structural design of the U-shaped mixing trough and the ribbon makes the material have no dead corners during the mixing process, and the material can be fully mixed and easily discharged, reducing the residue of the material in the equipment.

Gentle treatment: Low shear force design protects the activity of heat-sensitive ingredients (such as probiotics) and avoids high temperature damage. The speed is adjustable (20-40rpm) to adapt to different material characteristics (powder, granules or liquid addition).

Ribbon mixers are widely used in the production of various animal nutrition products, including but not limited to.

Compound feed: Mix corn, soybean meal, bran, premix and other raw materials evenly to ensure balanced nutrition of feed.

Concentrated feed: Mix multiple high-concentration nutrients with carriers evenly to provide high-quality raw materials for the production of compound feed.

Premix: Mix small but key ingredients such as vitamins, trace elements, amino acids and other ingredients with carriers evenly to ensure their uniform distribution in the final feed.

Pet food: Suitable for mixing raw materials of various dry food, snacks and other pet foods to ensure the nutrition and palatability of the products.

It is very important to choose a suitable animal nutrition product ribbon mixer according to different production requirements. The following are selection recommendations and detailed introductions for different production requirements.

Small-scale test (100-500L): Suitable for small-batch tests and laboratory research and development needs of 100-500 liters, and can quickly and effectively mix small batches of raw materials.

Medium-scale production (500-2000L): Suitable for farms, OEM factories and other places, with high mixing efficiency and stable operation, suitable for daily production use in farms and other places.

Large-scale continuous (2000L+): Suitable for large-scale production of 2000 liters and above, it needs to be equipped with an automated feeding system. Equipped with an automated feeding system, it can realize an automated production line and improve production efficiency and consistency.

When choosing a ribbon mixer, animal nutrition product manufacturers should consider the following factors comprehensively.

Production capacity: Select the appropriate equipment model and volume according to the daily output or batch output.

Material characteristics: Consider the fluidity, particle size, humidity, and whether the material contains fiber or sticky components to select the appropriate ribbon structure and material.

Mixing uniformity requirements: According to the quality standards of the final product, select equipment that can meet the mixing uniformity requirements.

Equipment material: According to the corrosiveness and other characteristics of the material, select the appropriate barrel and stirring component materials, such as carbon steel, stainless steel, etc.

Automation level: According to the automation level of the production line, choose whether to equip with automatic feeding, discharging, weighing and other auxiliary systems.

In the field of animal nutrition product production, high-quality ribbon mixers are essential. Dahan Machinery focuses on the research, development, production and sales of mixers and mixers. Its horizontal ribbon mixer uses a U-shaped tubular bin and a double-layer, non-directional ribbon coiled mixer shaft to achieve material convection mixing, with a mixing uniformity of over 99%. The equipment is made of a variety of materials and can be customized according to material properties and hygiene levels. We can make a suitable mixer for you according to your mixing requirements.

In modern livestock and poultry farming and feed processing industries, the uniformity and quality of animal nutrition products directly affect breeding benefits and animal health. With its unique structural design and efficient mixing performance, the ribbon mixer for animal nutrition products has become a key equipment to ensure balanced feed nutrition and improve product quality. From compound feed to special animal nutrition supplements, it provides solid protection for the healthy growth of animals with precise mixing technology.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.