Chemical Powder Crushing and Mixing Machine is made of 304/316L stainless steel, which can accurately achieve fine crushing of raw materials of 0.1-5mm and high uniformity mixing with CV value ≤5%. Its integrated design significantly reduces material transfer loss, adapts to various chemical powders such as pigments, plastic masterbatches, pesticide formulations, and supports customized requirements such as explosion-proof, temperature control, vacuum, etc., and flexible batch processing of 5-1000kg.

Chemical powder crushing and mixing machine can be deeply customized according to the specific needs of customers to meet the special requirements of different industries and materials.

Customizable: For high-viscosity materials (such as hot melt adhesive powder, asphalt powder), anti-stick inner wall coating and scraper cleaning system can be customized,

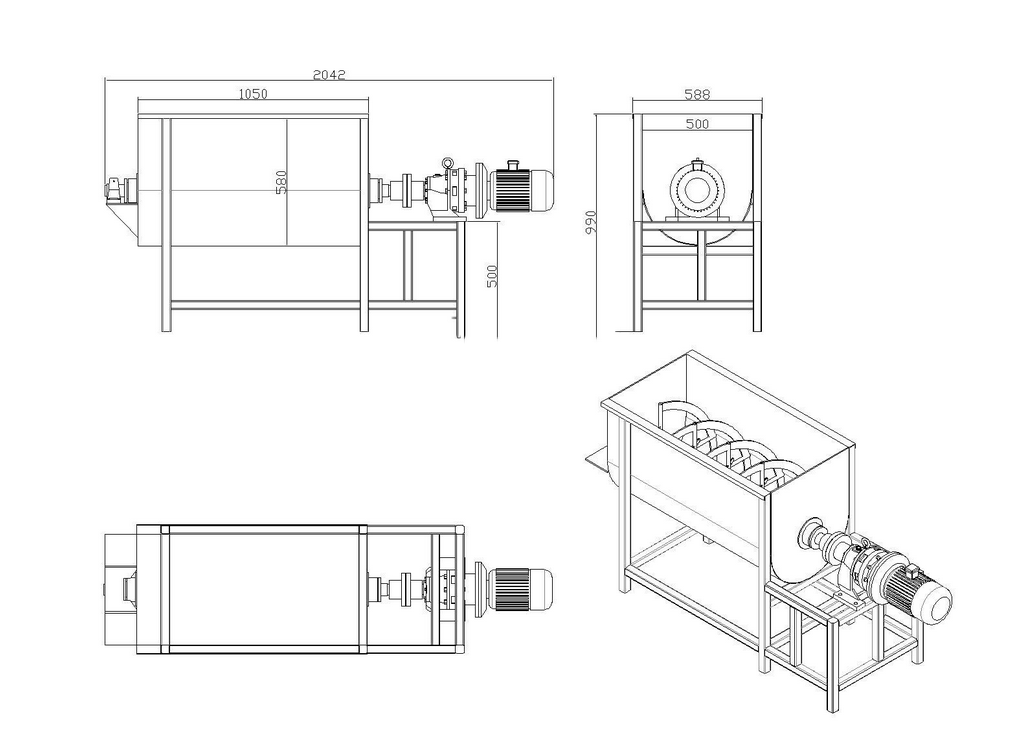

Integrated design: Integrates crushing and mixing functions, and realizes fine crushing of raw materials of 0.1-5mm and high uniformity mixing with CV value ≤5% through bidirectional spiral belt or three-dimensional motion structure.

Intelligent and precise control: equipped with PLC automation system, which can preset the speed (20-100rpm), mixing time (5-30min) and temperature parameters (-20℃~200℃), support formula storage and real-time load monitoring.

Corrosion-resistant and wear-resistant structure: 304/316L stainless steel, tungsten carbide coating or plastic lining material are used, suitable for strong acid, strong alkali and high hardness materials (Mohs hardness ≥7).

Safe and low energy consumption: fully enclosed structure with pulse dust removal (recovery rate>99%), dust overflow <1mg/m³; optimized power system makes the power consumption per ton of material only 2.5-3.5kWh, and noise control <75dB.

The chemical powder crushing mixer integrates the two core functions of crushing and mixing, and realizes material processing through mechanical force. During the mixing process, the ribbon mixer relies on the convection movement of the inner and outer layers of reverse ribbons to form a three-dimensional circulation of the material in the axial and radial directions, and the mixing uniformity can reach 99.5%.

The chemical powder crushing and mixing machine is designed for the chemical, pharmaceutical, pesticide and food additive industries. It integrates crushing and mixing functions, and can achieve fine crushing of raw materials of 0.1-5mm and high uniformity mixing with CV value ≤5%.

Fine chemicals: In the production of pharmaceutical intermediates and electronic chemicals, it is used to mix active ingredients and excipients to ensure uniform distribution of active ingredients of drugs.

New energy materials: In the production of positive and negative electrode materials of lithium batteries, raw materials such as lithium iron phosphate and graphite are mixed to ensure the consistency of battery performance.

Paint and ink: Disperse and mix titanium dioxide, pigments, etc. to improve the hiding power and color stability of coatings; nano-crush UV ink raw materials to enhance the printing suitability of inks.

Plastics and rubber: Mix plastic particles and additives to improve the mechanical properties of plastic products; premix rubber raw rubber and vulcanizer to improve the vulcanization efficiency of rubber products.

|

Model |

LHY-0.25 |

LHY-0.5 |

LHY-1 |

LHY-1.5 |

LHY-2 |

LHY-3 |

LHY-4 |

LHY-6 |

LHY-8 |

LHY-10 |

|

One-time mixing (kg) |

100-150 |

200-300 |

400-600 |

600-900 |

800-1000 |

1200-1800 |

1600-2400 |

2400-3600 |

3200-4800 |

4000-6000 |

|

Mixing time (min) |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

|

Mixing speed (r/min) |

60 |

55 |

45 |

40 |

35 |

25 |

25 |

20 |

15 |

15 |

|

Motor power (kw) |

3-5.5 |

4-11 |

7.5-15 |

11-18.5 |

15-22 |

18.5-30 |

22-37 |

37-55 |

37-55 |

45-75 |

|

Weight (kg) |

500 |

900 |

1800 |

2500 |

3200 |

4100 |

5100 |

6300 |

7500 |

|

Our equipment has served 500+ customers, helping them increase production capacity by 40% and reduce energy consumption by 25%. See how actual cases solve industry problems such as uneven crushing and cross contamination!

Pharmaceutical Group: Because the production of new sustained-release capsules requires nano-level mixing of active ingredients and excipients, a customized dual-axis gravity-free mixer was purchased, equipped with an ultrasonic dispersion device and a nitrogen protection system. After operation, the mixing uniformity increased from 95% to 99.8%, and the product qualification rate increased by 22%.

New Energy Materials Enterprise: In order to solve the batch stability problem of lithium battery positive electrode materials, a ribbon mixer with pre-crushing function was introduced to integrate the crushing and mixing processes. The production cycle was shortened by 40%, the particle size distribution CV value was reduced from 8% to 3%, the battery cycle life was increased by 15%, and the annual production capacity was increased to 100,000 tons.

Coatings Manufacturer: In view of the problem of pigment dispersion in water-based coatings, a mixer with high-speed shear blades was customized, combined with an online particle size detector. Pigment dispersion efficiency is increased by 60%, coating storage stability is extended from 6 months to 18 months, and product glossiness is increased by 12 units.

When purchasing a suitable mixer, we can first make a simple judgment based on our own needs.

Material property evaluation: clarify the hardness, viscosity, corrosiveness, heat sensitivity and other characteristics of the material, and select suitable materials and structures. For example, explosion-proof equipment is required for handling flammable materials, and drying function is required for handling hygroscopic materials.

Process parameter matching: select the corresponding model of equipment according to the target crushing particle size, mixing uniformity, and production capacity requirements. If multiple processes are required, consider integrated equipment to reduce intermediate links.

Energy consumption and maintenance cost: compare the energy efficiency level of the equipment, give priority to energy-saving products; understand the replacement cycle and cost of wearing parts, and evaluate the long-term economic efficiency.

The "Dual Power Integrated System" developed by Dahan Machinery Technology Co., Ltd. adopts a modular design to achieve high-precision mixing with adjustable crushing fineness of 0.1-5mm and CV value ≤3%. It provides 304 stainless steel standard models (5-1000kg batches), 316L stainless steel/ceramic lining anti-corrosion models and ATEX certified explosion-proof models (nitrogen protection). It has passed ISO9001 and CE certifications, with an annual production capacity of 800 sets, equipped with free trial machines, process training and 24-hour after-sales response services. It is the preferred partner in the field of chemical powder processing.

Choosing a suitable chemical powder crushing and mixing machine is a key step to ensure efficient and high-quality operation of chemical production. By deeply understanding your needs, the working principle and application areas of the equipment, and carefully considering the above purchase points, you will be able to find the most suitable solution for you, improve production efficiency, ensure product quality, and achieve sustainable development.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.