Chicken Meat Ribbon Mixer is a mixer developed for the animal protein powder, meat and bone meal, and feed additive industries. It features an optimized ribbon structure design to ensure uniform mixing of chicken powder with nutrients such as vitamins and minerals. Made of stainless steel, it ensures hygienic mixing of the chicken powder. Our chicken powder ribbon mixers support non-standard customization and variable frequency speed control, allowing for flexible adjustment of the mixing speed according to the moisture content and particle size of the chicken powder. This ensures effective mixing while preventing over-mixing that could lead to material overheating and spoilage. The large-diameter discharge port, coupled with a pneumatic gate valve control, ensures fast discharge and low residue, reducing material waste. A pre-installed cleaning port on the machine body facilitates cleaning and effectively prevents cross-contamination of flavors between different batches.

The Chicken Meat Ribbon Mixer offers advantages such as anti-caking, no pollution, customization, and increased production capacity. Made of corrosion-resistant and clean stainless steel, it ensures uniform mixing without residue and stable performance, making it the preferred equipment for chicken powder mixing and processing.

Anti-caking: The exclusive spiral ribbon mixing structure creates strong convection circulation of materials, effectively breaking up clumps of moisture-absorbing chicken powder, allowing the chicken powder to fully blend with various auxiliary ingredients, resulting in high mixing uniformity.

Pollution-free structure: All parts of the machine that come into contact with materials are made of stainless steel, with finely polished inner walls to eliminate unsanitary corners, ensuring corrosion resistance and rust prevention, and eliminating metal impurities.

Fully sealed dustproof design: The horizontal enclosed tank combined with a tight shaft end seal prevents dust dispersion during mixing, avoiding moisture absorption and spoilage of the chicken powder, while also reducing raw material waste.

Low residue discharge: The large-diameter discharge port design ensures smooth and thorough discharge, resulting in extremely low material residue and reducing the loss of high-protein raw materials.

Customized production: Single/double spiral ribbon structures, equipment volume, and speed control methods can be customized according to customer capacity requirements and workshop conditions. Spraying, heating, and other functions can also be added to adapt to diverse production needs.

Easy to clean and prevents cross-contamination of flavors: The smooth stainless steel inner wall eliminates residue and dead corners, allowing for quick and easy cleaning during batch changes and effectively preventing cross-contamination of flavors between different materials, ensuring product purity.

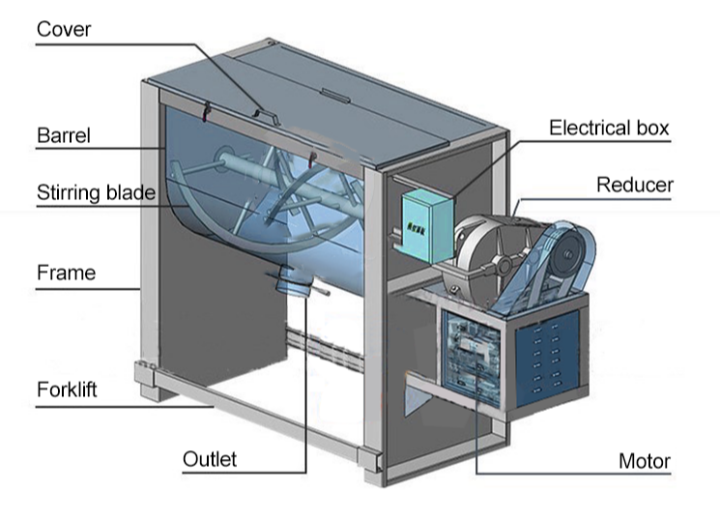

The main body of the Chicken Meat Ribbon Mixer features a horizontal, enclosed tank structure, equipped with a customized single/double ribbon mixing spindle. The scientifically arranged ribbon blades quickly break up clumps of chicken powder, achieving uniform mixing. The tank ends feature sealed caps and precise shaft end sealing devices to effectively prevent dust leakage and moisture ingress. A large-diameter discharge port at the bottom, combined with pneumatic or manual discharge valves, ensures smooth discharge with low residue. The overall structure is compact and practical, balancing mixing efficiency and ease of use.

During operation the Chicken Meat Ribbon Mixer uses a motor-driven reducer to rotate the spiral main shaft within the horizontal tank. The opposing pushing action of the inner and outer spiral ribbons creates a cyclical motion of axial convection and radial diffusion, quickly breaking up clumps of moisture-absorbing chicken powder and ensuring thorough mixing with various additives.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The Chicken Meat Ribbon Mixer, with its superior materials and stable performance, has won recognition from various customers, successfully serving clients in multiple sectors and solving problems such as material clumping, contamination, and insufficient production capacity.

Small Pet Food Factory: Previously, using a conventional mixer resulted in rust on the inner wall due to the material's inability to withstand the corrosion of chicken powder and oils, leading to raw material contamination. Purchasing a stainless steel chicken powder spiral ribbon mixer with a finely polished surface and no unsanitary corners completely solved the corrosion and rust problems and raw material contamination issues.

Aquatic feed mills: Primarily producing high-protein aquatic feed, with chicken meal as the core ingredient. Previously, due to poor sealing and high residue in the mixing equipment, not only was there the problem of chicken meal dust waste, but also batch-to-batch material residue led to deviations in feed nutrient ratios. After selecting a chicken meal ribbon mixer, the 316L stainless steel material is well-suited to the characteristic of chicken meal containing trace amounts of oil, is corrosion-resistant, and easy to clean, reducing cleaning time by 60% during batch changes; the fully enclosed tank with a precision sealing design prevents dust leakage.

Large-scale aquaculture farms: Need to mix chicken meal with corn, soybean meal, etc., to produce high-protein feed, requiring extremely high feed hygiene to avoid affecting the health of laying hens and egg production quality. After introducing multiple chicken meal ribbon mixers, the equipment's all-stainless steel structure has no unsanitary corners, resists long-term corrosion from chicken meal oil, and has no rust or contamination issues even after long-term use, meeting the hygiene standards for feed processing in the aquaculture industry. The equipment's mixing capacity can meet the processing needs of 2 tons of feed per day.

The Chicken Meat Ribbon Mixer supports 24/7 continuous operation. Its industrial-grade heavy-duty design, equipped with a high-temperature cooling system and reinforced transmission structure, meets the demands of high-load production around the clock. Key components such as the motor, reducer, and bearings have been durableized and feature intelligent temperature control and overload protection to ensure stable and high-speed mixing performance during continuous operation. The equipment also supports automated production lines, seamlessly integrating with upstream and downstream conveying and packaging equipment for unmanned continuous operation.

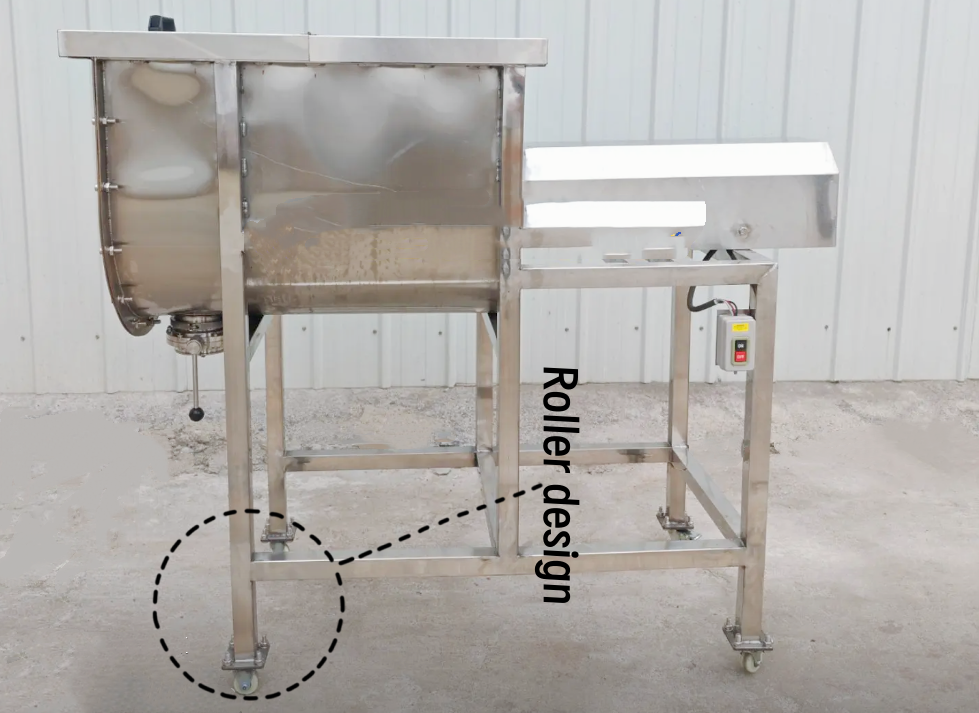

The chicken meal ribbon mixer can be customized into a mobile model. Simply equip it with heavy-duty casters and a traction device for easy and flexible transport between different production areas. The equipment features a modular, quick-connect interface design for rapid connection to power and feeding systems, supporting immediate use. The mobile structure significantly improves equipment utilization while maintaining equivalent mixing performance, making it particularly suitable for flexible production scenarios such as multi-workshop sharing, temporary production increases, and outdoor operations.

The Chicken Meat Ribbon Mixer can be equipped with multiple practical functions as needed, supporting explosion-proof configuration, vacuum mixing, liquid addition system, and intelligent control system. Various configurations can be added as required to adapt to different production conditions and processing needs.

Explosion-proof Configuration: The chicken meal ribbon mixer can be equipped with a professional explosion-proof configuration as needed. The whole machine's explosion-proof design is suitable for production environments with high dust concentrations and flammable and explosive risks.

Vacuum Mixing Configuration: This machine can be equipped with a vacuum mixing function, completing the chicken meal mixing operation in a sealed vacuum environment, effectively preventing the chicken meal from oxidizing and deteriorating due to contact with air, and locking in the nutritional components of the raw materials.

Liquid Addition System: A precise liquid addition system can be customized and added, allowing for quantitative and uniform spraying of liquid additives such as oils, fish oil, and probiotic liquids needed in chicken meal processing, synchronously mixing and blending with the powder for more thorough mixing.

Intelligent Control System: Supports upgrades to an intelligent control system, equipped with a touch screen operation screen, allowing for quick setting of parameters such as mixing time, speed, and unloading mode, achieving automated one-button start and stop.

DaHan Machinery's Chicken Meat Ribbon Mixers start at $1000. Pricing is determined based on the core configuration and actual needs. Basic models cover a capacity of 500L or less and feature a 304 stainless steel construction, suitable for small-scale chicken meal mixing. Medium and large models, with increased capacities of 1000-3000L and a double-ribbon reinforced mixing structure, have correspondingly adjusted prices. Optional features such as explosion-proof design, vacuum mixing, liquid addition systems, or upgrades to 316L stainless steel construction will be priced according to customized requirements. As a direct manufacturer, we eliminate intermediaries, optimizing costs through modular production. We also provide warranties and after-sales support, ensuring customers of all sizes can obtain high-performance, cost-effective equipment.

The Chicken Meat Ribbon Mixer is specifically designed for these powdery/small granular materials. With its scientific structural design and precise performance configuration, it has become the core equipment in the chicken meal mixing and processing process, perfectly solving the pain points of ordinary mixers such as easy clumping, uneven mixing, and contamination of materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.