Clay Glaze Horizontal Mixer is a clay glaze horizontal mixer designed for the ceramic industry. It adopts an innovative double-layer spiral ribbon stirring structure to achieve high uniformity mixing (CV value <5%) and greatly improve the glaze quality. The equipment provides a variety of capacity options from 0.3-10m³, covering all needs from small studios to large factories, and supports different needs from 220V household electricity to industrial automation production lines. Wear-resistant and anti-corrosion materials extend the service life, the intelligent control system achieves precise adjustment, and an optional vacuum degassing device reduces the bubble rate.

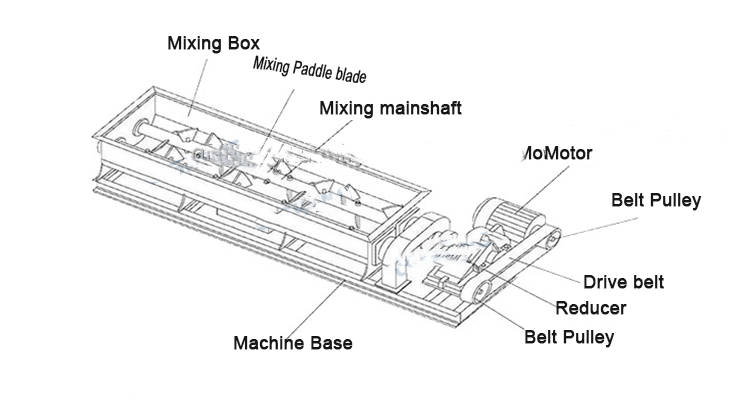

The horizontal mixer adopts a horizontal barrel structure and is equipped with a bidirectional spiral ribbon stirring blade. The inner layer is quickly advanced and the outer layer is reversely mixed to ensure no dead angle mixing, meeting the fine preparation needs of glazes of different viscosities.

U-shaped cylinder and anti-stick inner wall: The main body adopts a U-shaped horizontal cylinder design. The inner wall in contact with the glaze is made of 304 or 316L stainless steel. After mirror polishing, the surface roughness Ra≤0.8μm ensures that the glaze is not easy to adhere.

Multi-layered spiral ribbon stirring paddle: The stirring system is the core of the horizontal mixer, usually equipped with a multi-layered spiral ribbon stirring paddle. The outer large spiral ribbon transports the material from both ends to the middle, and the inner small spiral ribbon pushes the material from the middle to both ends, forming a two-way convection cycle.

Variable frequency speed regulation and sealing system: The power system is equipped with a variable frequency motor, which supports 0-100rpm stepless speed regulation, and can flexibly adjust the stirring speed according to the glaze formula and mixing process requirements.

When clay, quartz, feldspar and other glaze raw materials are put into the U-shaped cylinder according to the formula ratio, the stirring shaft drives the multi-layered spiral ribbon blades to start rotating. During the rotation process, the material first moves axially under the thrust of the spiral ribbon. The outer spiral ribbon pushes the material from both ends of the cylinder to the middle, and the inner spiral ribbon pushes the material from the middle to both ends in the opposite direction, forming a continuous axial convection. At the same time, the centrifugal force generated by the rotation of the blades causes the material to roll and diffuse in the radial direction, and the materials at different positions and heights are constantly interlaced and mixed.

Adopting a bidirectional spiral ribbon stirring structure, the mixing uniformity reaches more than 98%, and the batch is completed quickly in 8-12 minutes; the wear-resistant and anti-corrosion design extends the service life by 3-5 times!

High-precision mixing uniformity: Through the optimized stirring blade structure and motion trajectory, it can ensure that trace colorants, additives and other ingredients are evenly dispersed in a large amount of basic glaze.

Flexible production adaptability: The horizontal mixer provides a variety of specifications and models, with a volume ranging from 50L to 5000L, which is suitable for production needs of different scales.

Energy saving and low noise operation: With energy-saving motors and optimized transmission systems, the new clay glaze horizontal mixer reduces energy consumption by 20%-30% compared to traditional mixers.

Wear-resistant and anti-corrosion treatment technology: In view of the fact that glaze often contains hard particles such as quartz, the mixing blades and the inner wall of the cylinder are treated with special wear-resistant alloy steel or ceramic lining, and the service life can reach 3-5 times that of ordinary carbon steel.

Intelligent control system upgrade: The new generation of products is equipped with a PLC touch screen control system, which can achieve multi-speed adjustment (0-60rpm stepless speed change, temperature monitoring alarm, and timed automatic shutdown function.

From small-batch creations in art studios to large-scale production in industrial parks, our horizontal mixers provide perfect solutions.

Art ceramics: Clay glaze horizontal mixers can accurately mix various rare pigments and special additives to help achieve complex glaze effects such as kiln-changed glazes and crystallized glazes

Daily ceramic production: Horizontal mixers are used to mix basic glazes in large quantities. Through a stable and efficient mixing process, the quality of each batch of glazes is ensured to be consistent, thereby ensuring the appearance quality and performance of daily ceramic products such as tableware and tea sets.

Architectural ceramics manufacturing: Clay glaze horizontal mixers can mix a variety of functional glazes such as wear-resistant glazes, bright glazes, and matte glazes. Uniform glaze mixing can improve the wear resistance, glossiness and anti-fouling properties of the glaze.

Enamel product processing: The mixing quality of glazes directly affects the flatness, glossiness and corrosion resistance of the enamel surface. The horizontal mixer can evenly mix raw materials such as silicon dioxide and boron oxide in the enamel glaze to ensure that the enamel products have a smooth and beautiful surface and excellent physical and chemical properties after firing.

Analyze the key factors for buying a horizontal mixer, provide professional selection suggestions, and help you choose the most cost-effective mixing solution!

Selection based on production scale: Clarifying the production scale and output requirements of the company is the first step in selection. If the monthly glaze usage is small, a small horizontal mixer of 50-200L can be selected. If the daily output is high, it is recommended to choose large and medium-sized equipment above 500L.

Consider glaze characteristics: Different glaze formulas have different characteristics, such as viscosity, particle size, corrosiveness, etc. For glazes with higher viscosity, models with strong stirring force and good anti-sticking performance should be selected; glazes containing corrosive ingredients (such as boric acid) require equipment to use corrosion-resistant materials (such as 316L stainless steel).

Note equipment materials and hygiene standards: Since glazes directly affect the quality and safety of ceramic products, the parts of the mixer that come into contact with the glaze must be made of materials that meet food hygiene standards or ceramic industry standards. 304 or 316L is preferred Stainless steel material, and confirm whether the surface treatment process of the equipment meets the mirror polishing requirements.

We provide professional customization services, matching the optimal configuration according to your actual production needs, whether you are an art studio, a medium-sized ceramic factory or a large-scale intelligent manufacturing company, you can get an exclusive mixing solution!

Economic configuration for small studios: We provide a small horizontal mixer with a capacity of 0.3-0.5m³, with a compact design (footprint <2㎡) to adapt to limited space, and support 220V household voltage, without additional power transformation . The manual unloading door and basic frequency conversion control are used to ensure mixing uniformity while reducing equipment costs. It is particularly suitable for small-batch, multi-variety glaze experiments and handmade ceramic production.

Efficient solution for medium-sized production enterprises: For medium-sized ceramic enterprises with a daily output of 5-10 tons, the 1.5-3m³ capacity mixing unit adopts a hydraulically driven unloading door (opening and closing time <15 seconds) and a dual motor system (main mixing + unloading auxiliary) to greatly improve operating efficiency. The dust-proof and splash-proof sealing design reduces raw material waste, and a vacuum degassing device can be optionally equipped to further optimize the glaze quality and reduce bubble defects.

Large-scale factory automation integration solution: For modern ceramic industrial parks and large manufacturing enterprises, 5-10m³ large mixers integrate automatic feeding, online viscosity detection and central control systems to achieve accurate proportioning and real-time adjustment. Support remote monitoring and predictive maintenance, and seamlessly connect with equipment such as ball mills and spray dryers to build intelligent production processes.

As a key equipment for improving the quality and efficiency of ceramic production, the technological development of clay glaze horizontal mixers is always guided by the actual needs of users. We will continue to pay attention to the pain points of the industry, and through technological innovation, help customers cope with multiple challenges such as raw material fluctuations, rising labor costs, and increased quality requirements, and jointly promote the development of ceramic manufacturing towards intelligentization and greening.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.