Coffee Powder Mixer is a precision mixing equipment designed for the coffee industry. It uses food-grade 304 stainless steel and bidirectional spiral/three-dimensional mixing technology. It can achieve high-uniformity mixing with a CV value of ≤3% within 5-10 minutes, perfectly preserving the flavor characteristics of coffee powder from different origins and roasting degrees. Its low-speed (20-40rpm) design and no-dead-angle structure ensure gentle processing, avoid heat and flavor loss, support 5-500kg batch processing, meet the full-scenario needs from boutique coffee blending to commercial production, and is the core equipment for improving coffee quality.

With customized capacity to adapt to large and small production capacities, it can handle everything from small batches in boutiques to large-scale production in factories. Three-dimensional mixing achieves 99%+ uniformity, quickly completes mixing within 10 minutes, and locks in the aroma of coffee.

Create unique flavor: Coffee lovers can freely match coffee beans of different flavors according to their preferences to create a unique and exclusive blend.

Optimize extraction effect: Uniform coffee powder particles can achieve more consistent extraction, avoid over-extraction or under-extraction, and improve the overall flavor and taste of coffee.

Protect coffee flavor: The equipment fully considers the protection of coffee flavor during design and operation. The use of stainless steel and low-friction stirring parts reduces friction and heat generation with coffee powder, avoiding the loss of coffee aroma and flavor deterioration due to temperature increase.

Flexible customization: The coffee powder mixer can be flexibly customized according to different production needs and coffee varieties.

In the coffee industry, from boutique coffee shops to large-scale roasting factories, high-quality coffee powder mixers are the key to ensuring stable product flavor and improving production efficiency. We provide a variety of coffee powder mixers to meet different scale and process requirements.

Ribbon mixer: Especially suitable for large-scale coffee powder blending, with a mixing uniformity of up to 99%. Compared with ordinary mixing equipment, the mixing time is greatly shortened. The maximum processing capacity of a single batch can reach 500kg.

Three-dimensional motion mixer: It is very suitable for the production of instant coffee, where 200-400 mesh ultra-fine coffee powder needs to be evenly mixed with auxiliary materials such as sugar and non-dairy creamer, and it can also solve the problem of easy agglomeration of ultra-fine powder.

Paddle mixer: It performs well in the preparation of flavored coffee. It can homogenously mix basic coffee powder with solid seasonings such as cinnamon powder and cocoa powder. At the same time, the high-pressure atomizing nozzle can achieve uniform spraying of liquid spices (such as caramel syrup).

Desktop three-dimensional mixer: Designed for coffee shops and small bakeries, it is suitable for small batches (5-20kg) of customized blending needs, and can quickly switch between different recipes. The equipment volume is 10-50L, with a transparent observation window, which is convenient for operators to observe the mixing situation at any time.

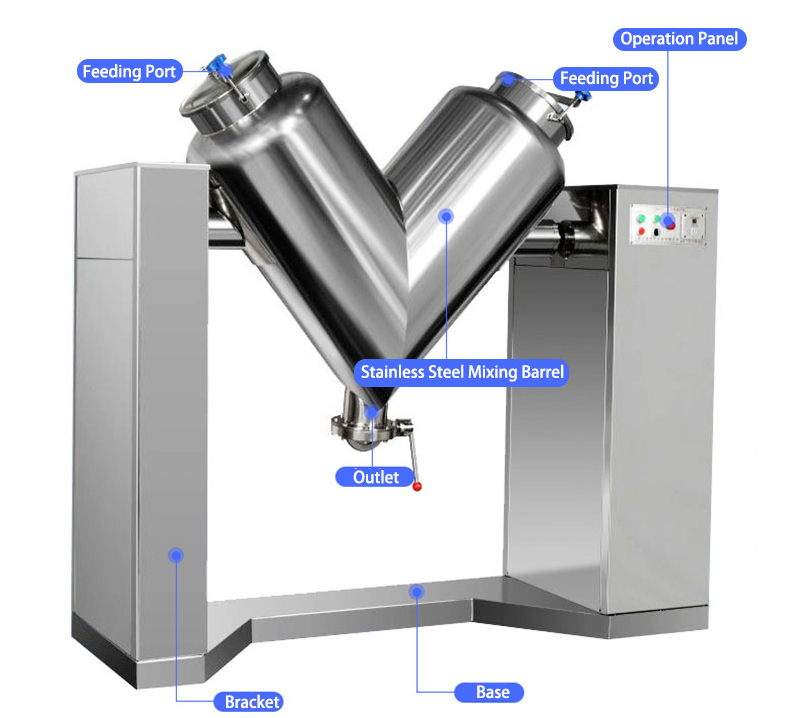

The coffee powder mixer is mainly composed of core components such as mixing container, stirring device, drive system, feed port and discharge port.

Mixing container: Mixing containers are mostly made of stainless steel, which not only has good corrosion resistance to ensure that coffee powder is not contaminated, but also effectively prevents static adsorption, avoids coffee powder residue and agglomeration.

Stirring device: The stirring device is the core component of the coffee powder mixer, and its structure and type directly affect the mixing effect. Common stirring methods include paddle type, spiral ribbon type and planetary type.

Drive system: The drive system consists of a motor, a reducer and a transmission component to provide stable and adjustable power for the stirring device.

Feeding port and discharging port: The design of the feeding port focuses on convenience and sealing, and materials can be added by manual feeding or automatic conveying. Some mixers are also equipped with dust collection devices to prevent coffee powder from flying during the feeding process and keep the working environment clean.

When the coffee powder mixer is started, the driving system drives the stirring device to start running. Taking the spiral ribbon stirring device as an example, the reverse rotation of the inner and outer spiral ribbons enables the coffee powder to form a unique "double circulation" movement mode in the mixing container. The outer layer of the spiral ribbon pushes the coffee powder from one end of the container to the other end, while the inner layer of the spiral ribbon pulls the coffee powder back from the other end to the starting end, forming a circular flow in the axial direction; the rotation of the stirring device also causes the coffee powder to produce strong stirring and shearing effects in the radial direction, causing the coffee powder to flip up and down and interweave with each other.

The equipment covers 5kg small experimental machines to 500kg commercial models, supporting the needs of powder, liquid addition and temperature control, meeting the full-scenario applications such as boutique blending, instant base material mixing, and flavored coffee preparation.

Coffee roasting factory: Large coffee roasting factories need to grind and blend coffee beans of different origins and roasting degrees, such as achieving a precise ratio of 70% Brazilian beans to 30% Ethiopian beans, and ensure the flavor consistency of each batch (CV value ≤3%). Use a large spiral ribbon mixer of 100-500kg/batch, with a nitrogen protection system to prevent oxidation.

Instant coffee production: In the production of instant coffee, it is necessary to evenly mix 200-400 mesh ultrafine coffee powder with auxiliary materials such as sugar and non-dairy creamer, and solve the problem of easy agglomeration of ultrafine powder. The three-dimensional motion mixer is combined with ultrasonic assisted dispersion and equipped with an inner lining of Teflon anti-sticking layer. The ideal effect can be achieved after mixing for 12 minutes, and the residual amount is less than 0.1%.

Flavored coffee preparation: When making flavored coffee, the basic coffee powder needs to be homogenously mixed with seasonings such as cinnamon powder and cocoa powder, and liquid spices such as caramel syrup can be sprayed at the same time. The paddle mixer is equipped with a high-pressure atomizing nozzle with an adjustable speed of 20-60rpm, which can make the distribution uniformity of the flavoring agent exceed 98%, meeting the flavoring needs.

Cafes & small bakeries: Cafes and small bakeries focus on small batches (5-20kg) of customized blending, and need to quickly switch between different recipes. The desktop three-dimensional mixer (volume 10-50L) is equipped with a transparent observation window and manual unloading function. It can complete a batch of mixing in 5 minutes, with a daily processing capacity of 200kg, and is flexible and adaptable to diversified production.

When choosing a coffee powder mixer, you can consider the following key selection requirements to determine the mixing equipment that suits you.

Accurately select capacity based on output: Output is the key factor in determining the capacity of a coffee powder mixer. When the daily output is less than 50kg, it is suitable to use a small machine of 5-50L to meet the needs of small batch customization; when the daily output exceeds 200kg, it is recommended to choose an automated model of more than 100L to ensure efficient production.

Determine the structure according to material characteristics: Material characteristics directly affect the selection of mixer structure. When processing deep roasted beans containing oil, an anti-sticking screw belt design is required to avoid material adhesion; when making flavored coffee, a spray system is required to ensure that liquid spices are added evenly.

Strictly control mixing efficiency: Mixing efficiency is a key consideration. High mixing uniformity can effectively avoid product quality problems and ensure the consistency of coffee flavor. At the same time, shortening the mixing time can significantly improve production efficiency. When selecting a model, you should give priority to equipment that has both uniform mixing effect and efficient mixing speed.

The price of coffee powder mixers varies greatly due to many factors. Capacity is one of the key influencing factors. Small 5-50L is suitable for scenarios with a daily output of less than 50kg, such as small batch customization of boutique coffee shops. This type of small equipment has a relatively low price due to its small processing capacity and relatively simple structure. Large-scale automated models above 100L can meet large-scale production with a daily output of more than 200kg, such as large coffee roasting factories. Their prices are higher due to their high production capacity, automated control and other complex functions. In terms of equipment quality and durability, products made of corrosion-resistant and easy-to-clean stainless steel, with well-designed transmission systems and agitators to ensure stability and durability, will be more expensive. Specific detailed price list We can make a detailed parameter price list for you based on your needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.