Crushing and Mixing Machine for Fertilizer Production is the core equipment for compound fertilizer manufacturing. It integrates crushing and mixing functions. It adopts wear-resistant manganese steel hammers and bidirectional spiral ribbon structure to achieve 0.1-3mm fine crushing of raw materials and high uniformity mixing with CV value ≤5%, and the processing capacity reaches 1-20 tons/hour. Equipped with intelligent PLC control system and 316L stainless steel anti-corrosion design, it is suitable for a variety of raw materials such as NPK and organic fertilizer. It has the advantages of low energy consumption (<3.5kWh/ton), corrosion resistance, and customizable anti-sticking/heating modules.

In fertilizer production, different types of crushing and mixing machines can be selected according to different production needs and raw material characteristics. The following are several common types of crushing and mixing machines for fertilizer production.

Double-shaft mixer: It consists of two rotating shafts, each shaft is equipped with a stirrer or mixing blade, which can achieve multi-directional and efficient mixing. It is suitable for mixing fertilizer raw materials with strong viscosity or occasions where highly uniform mixing is required.

Disc mixer: It consists of a horizontally rotating disc and a raised agitator, and mixing is achieved by rotation. It is suitable for mixing fertilizer raw materials with small particles and easy to crush, and can better maintain the particle size of the raw materials.

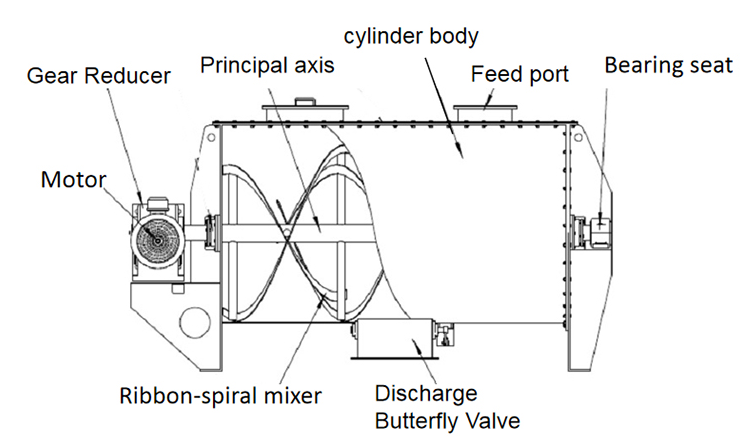

Spiral mixer: It consists of a spiral blade and a mixing drum, and mixing is achieved by the rotation of the spiral blade. It is suitable for mixing fertilizer raw materials with large particles and easy to agglomerate, and can effectively break the agglomeration and achieve uniform mixing.

Vertical mixer: It is a vertical cylinder structure with an agitator or agitator blade, which can achieve up and down, left and right mixing movements. It is suitable for mixing fertilizer raw materials with large particles or irregular shapes, and can effectively mix raw materials of different particle sizes.

In fertilizer production, crushing and mixing is the core link that determines product quality, and can avoid uneven nutrients causing differences in crop growth.

Improve nutrient uniformity: Different fertilizer raw materials may have different particle sizes and physical properties. By crushing, raw materials with large blocks or particles can be refined to increase their specific surface area, making it easier to distribute evenly with other raw materials during mixing.

Improve physical properties: The fine particles after crushing are easier to agglomerate, forming a more uniform and stable granular fertilizer, reducing dust, and improving the fluidity and anti-caking properties of the fertilizer.

Promote chemical reactions: In the production process of some compound fertilizers or BB fertilizers, fine raw material particles can increase the contact area, which is conducive to chemical reactions or physical adsorption between raw materials, and improve reaction efficiency and product quality.

Meet the requirements of subsequent processes: Some fertilizer production processes, such as granulation and extrusion, have specific requirements for the fineness and uniformity of raw materials. The crushing mixer can provide raw materials that meet these requirements.

Fertilizer production crushing mixer usually consists of crushing system, mixing system, transmission device, feeding and discharging device, and control system.

Crushing system: It is the key part to achieve raw material refinement. Common types include hammer type, claw type and roller type.

Mixing system: It determines the uniformity of fertilizer nutrients. Common mixing structures include spiral ribbon type, paddle type and double-axis gravity-free type.

Transmission and other components: The transmission consists of a motor, a reducer, and a coupling, etc., which provide stable power for the crushing and mixing system.

When the fertilizer production crushing mixer is started, the material first enters the crushing system. Taking the hammer mill as an example, the high-speed rotating hammer (linear speed can reach 80-100m/s) violently hits the material entering the crushing chamber to crush it. Under the action of centrifugal force and airflow, the crushed material collides and rubs with the screen. The material that meets the particle size requirements passes through the screen and enters the mixing system, and the larger particles continue to be crushed in the crushing chamber. After entering the mixing system, different types of mixers achieve uniform mixing of materials in their own unique ways.

The fertilizer production crushing mixer can mix a variety of materials, mainly including the following categories.

Compound fertilizer production: The fertilizer production crushing mixer crushes and mixes basic fertilizer raw materials such as nitrogen, phosphorus, and potassium with various trace elements according to the formula ratio. By precisely controlling the crushing particle size and mixing time, the nutrients in the fertilizer particles are evenly distributed, and compound fertilizer products that meet the needs of different crops are produced.

Bio-organic fertilizer production: When processing organic materials such as livestock and poultry manure and crop straw, the crushing system is first used to crush the materials to a suitable particle size to increase the surface area for microbial decomposition. Then it is fully mixed with additives such as microbial agents and humic acid in the mixing system to promote the uniform fermentation process.

Blended fertilizer (BB fertilizer) production: Blended fertilizer is a direct mixture of single fertilizers with different particle sizes and nutrient contents. The crushing mixer can moderately crush some raw materials to adjust the particle size according to the formula requirements, and then mix them with other raw materials with high precision to ensure that the components are evenly distributed.

Special fertilizer production: For special fertilizers such as water-soluble fertilizers, slow-release fertilizers, and trace element fertilizers, the crushing mixer can accurately control the crushing fineness and mixing uniformity of the materials.

In the process of fertilizer production, faced with the mixing difficulties of special materials such as high viscosity and corrosive materials, the fertilizer production crushing and mixing machines effectively ensure the mixing efficiency and product quality through targeted technical configuration and process optimization. The following is a detailed explanation of the solutions for special materials.

High viscosity materials: For highly viscous materials such as mature biogas residue, a 20rpm rotating scraper is configured to continuously scrape off the attachments on the inner wall of the cylinder, and the polished inner wall with a roughness of Ra≤0.8μm is used to reduce the adhesion of the materials, which not only ensures the mixing efficiency, but also facilitates cleaning and avoids cross contamination.

Corrosive additives: When handling corrosive additives such as sulfuric acid, ceramic and stainless steel composite linings are used to isolate corrosion, and IP65 protection grade anti-corrosion motors are used to build a full-process anti-corrosion system from the core components of the equipment to the power system to extend the service life of the equipment.

Organic-inorganic compound: When producing organic-inorganic compound fertilizers, a segmented mixing process is used. First, dry-mix the solid raw materials at medium or low speed for 1-2 minutes to achieve preliminary dispersion, and then spray at low speed for 3-5 minutes to fully penetrate the liquid nutrients and increase the mixing uniformity to more than 98%.

As a professional manufacturer in the field of fertilizer production crushing mixers, we strictly control the entire production process and ensure the quality of equipment with high-quality raw materials and advanced processes. Relying on a professional team and cutting-edge technology, we can provide customized solutions such as 20rpm rotary scraper and Ra≤0.8μm polished inner wall for high-viscosity materials, ceramic stainless steel composite lining and IP65 anti-corrosion motor for corrosive materials for special materials; the production capacity covers 50kg to several tons per hour, and the equipment shape and installation method can be optimized according to the site to meet customers' non-standard customization needs in all aspects and enable efficient operation of fertilizer production.

Fertilizer production crushing mixer is an indispensable key equipment in the fertilizer production line, and its performance directly affects the quality and production efficiency of fertilizer products. When selecting and using this type of equipment, it is necessary to comprehensively consider the characteristics of raw materials, production requirements, equipment type, operation and maintenance, etc. Through reasonable selection and standardized operation and maintenance, the role of the crushing mixer can be fully utilized to provide a strong guarantee for the high quality and high efficiency of fertilizer production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.