Crushing and Mixing Machine is a multifunctional equipment that combines the two functions of crushing and mixing. It can integrate the two functions of crushing (or crushing, shredding) and mixing (stirring) of materials. It can crush and mix raw materials of different particle sizes or shapes to produce uniform mixtures or particles, playing an important role in many industries.

The advantages of the crushing and mixing machine are its high efficiency, space saving and human resource saving, and reduced production costs.

Save working time: Integrating two independent processes into one device greatly shortens the material processing time and reduces the material transfer links and waiting time between different equipment.

Save space: One device replaces the two devices that may

have been required, the crusher and the mixer, significantly reducing the floor space of the production line.

Optimize product quality: Mixing immediately after crushing can avoid stratification, agglomeration or property changes of the crushed materials due to standing or transporting, which helps to ensure the uniformity and stability of the final mixture.

Flexible customization: Customized design can be made according to the characteristics and production needs of different industries and different materials. Users can choose different crushing parts, mixing systems, feeding and discharging methods, as well as the materials, specifications and functional configurations of the equipment.

High mixing uniformity: The special design and efficient operation of the mixing system can make the materials achieve extremely high mixing uniformity in a short time, regardless of the materials of different densities and particle sizes.

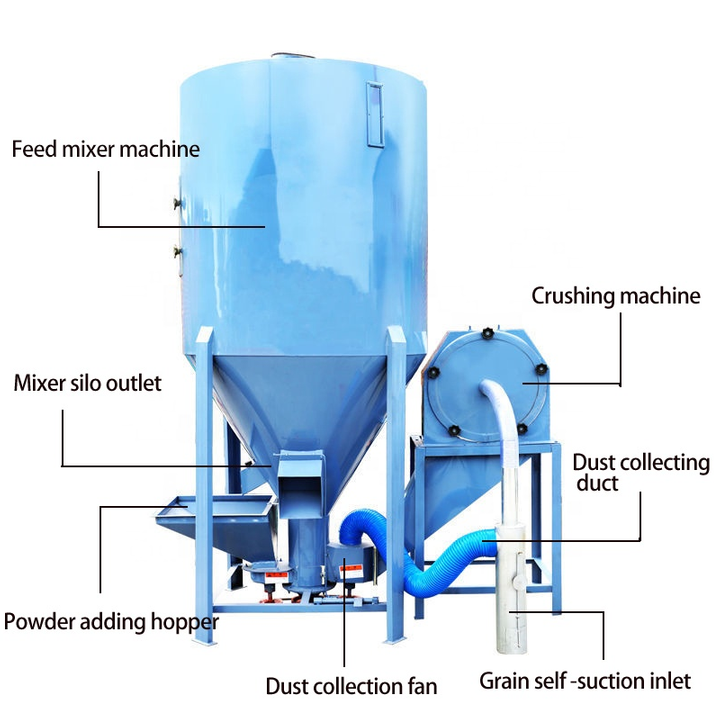

The structural design of the crushing mixer is closely centered around the two core functions of crushing and mixing, and is mainly composed of crushing chamber, mixing system and other parts.

Crushing chamber: This is the key area for achieving material crushing. It is usually made of high-strength wear-resistant materials, such as manganese steel or special alloy materials, to withstand the strong impact and friction of the material during the crushing process.

Mixing system: Located inside or connected to the crushing chamber, it consists of a mixing shaft, mixing blades, etc. The mixing shaft runs through the entire mixing area and is driven to rotate by the power system.

Feeding device and discharging device: The feeding device usually uses spiral conveying, vibrating feeding or belt conveying to smoothly feed the material into the crushing chamber. The discharging device is set at the bottom or side of the equipment and is equipped with a control valve or conveyor belt.

Power system and control system: The power system generally uses high-performance motors to provide sufficient power for the crushing and mixing process.

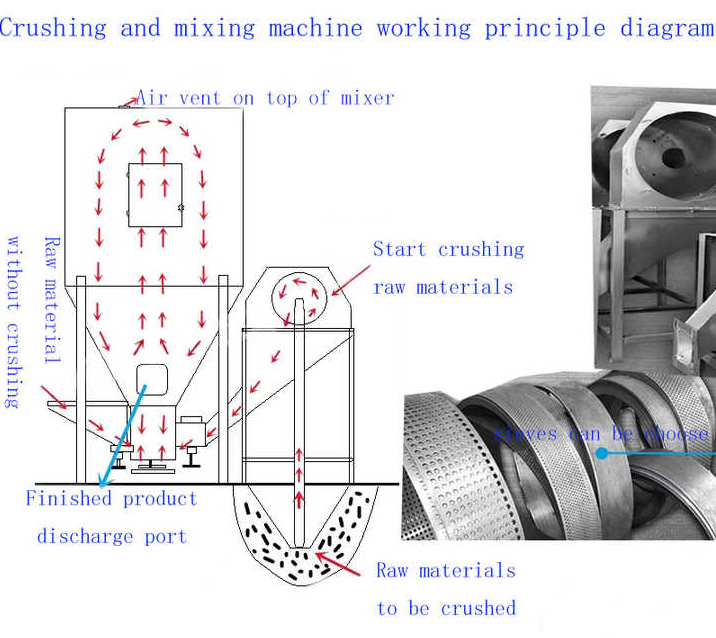

The working process of the crushing and mixing machine can be divided into two stages: crushing and mixing. The two work closely together to achieve high-speed processing of materials. In the crushing stage, after the material enters the crushing chamber through the feeding device, it is immediately subjected to high-speed impact and shearing by the crushing components. When the material is crushed to a certain extent, the mixing system begins to work and enters the mixing stage. The mixing shaft drives the mixing blades to rotate, so that the crushed material produces a complex motion trajectory in the mixing chamber. Under the dual action of axial and radial directions, the material continuously circulates and diffuses with each other to achieve uniform mixing.

Designed for feed production, chemical raw materials and pharmaceutical excipients, it realizes integrated crushing-mixing operation, improves efficiency by more than 30%, and meets the refined production needs of different industries.

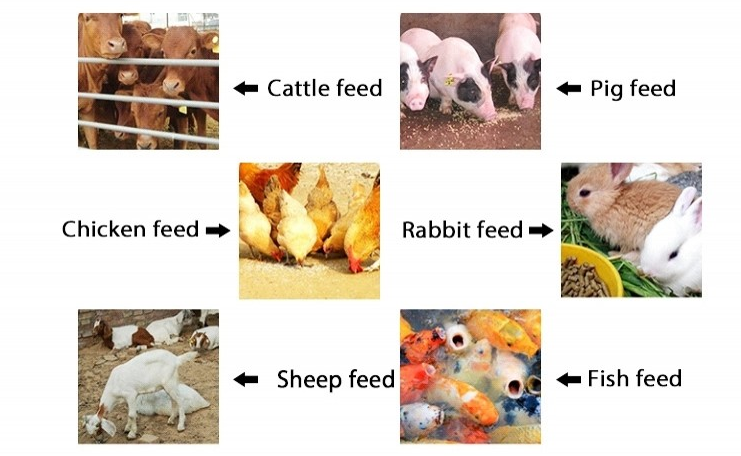

Feed industry: It can crush raw materials such as corn, soybean meal, and wheat bran into suitable particle sizes, and evenly mix them with various vitamins, minerals, amino acids and other additives to produce nutritionally balanced feed products.

Chemical industry: The pulverizer mixer can be used to pulverize and mix various chemical raw materials such as pigments, resins, additives, etc., to provide high-quality raw materials for subsequent chemical reactions, molding processing and other processes.

Food industry: Food processing has extremely high requirements for the hygiene of equipment. The pulverizer mixer is made of materials that meet food hygiene standards and can safely handle various food raw materials.

Pharmaceutical industry: In the pharmaceutical process, the quality of material pulverization and mixing directly affects the efficacy and safety of the drug. The pulverizer mixer can pulverize the drug raw materials into a particle size that meets the requirements of the preparation, and mix them evenly with the auxiliary materials to ensure that the dosage of the drug is accurate and the composition is uniform.

The pulverizer mixer is a device that performs dual processing of pulverizing and mixing materials. It is mainly used to process the following types of feed:

Energy feed: Corn, wheat, sorghum and other grains are common energy feeds. After pulverization, they can improve the digestibility and absorption rate of livestock and poultry and the palatability of feed, and provide carbohydrates for animal growth.

Protein feed: Soybean meal, fish meal, meat and bone meal, etc. are important sources of protein. Soybean meal is used in large quantities in pig and poultry feeds, and fish meal can improve the nutritional value of feeds. It is often used in aquatic products and young and high-yield livestock and poultry feeds.

Green feed: Green feeds such as alfalfa and ryegrass are rich in nutrients. When fresh, they can be chopped or crushed to feed ruminants directly, and can also be made into hay powder for compound feed.

Minerals and additives: Stone powder and calcium hydrogen phosphate are commonly used calcium and phosphorus supplements, which are added to feed to ensure the bone development of livestock and poultry.

Dahan Machinery Manufacturing Co., Ltd. is a company that focuses on the research and development and production of crushing and mixing machines. Its "crushing-mixing integrated system" achieves an adjustable crushing fineness of 50μm-5mm and a mixing uniformity of CV value ≤3%. The products cover three major series of feed, medicine, and chemical industry. It has passed ISO9001, CE and other certifications, serving more than 800 customers worldwide, providing full-process services from material testing to customized development, with an annual production capacity of 500 sets, and equipment exported to 30 countries, leading the industry development with modular design and intelligent control.

As a device that integrates material crushing and uniform mixing functions, the pulverizer mixer has greatly optimized the production process of many industries. It not only improves production efficiency and reduces operating costs, but also helps to ensure and improve the quality of the final product. With the continuous advancement of technology, the design of the pulverizer mixer will become more refined and intelligent to meet more diverse and higher-demand material processing needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.