Current Planetary Mixer with its unique planetary motion trajectory and multi-dimensional mixing capabilities, has become a standard solution in the mixing field. Its most significant feature is the planetary motion of the mixing blades: while revolving around the central axis of the mixing drum, the blades also rotate around their own axes. This composite motion trajectory comprehensively covers the entire mixing drum, fundamentally achieving dead-zone-free mixing and completely solving the problems of uneven mixing and material residue in traditional mixers. With a capacity range of 50L-5000L, and to adapt to the diverse discharge needs of various production lines, 1-3 discharge gates can be selected based on material characteristics and production capacity, enabling fast and thorough discharge and significantly improving production efficiency.

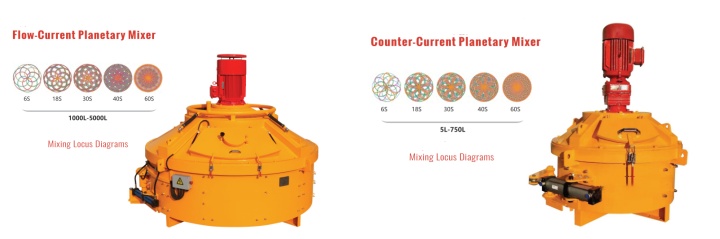

Based on the difference in the direction of movement of the mixing blades, we produce two main types: Counter-Current Planetary Mixers and Flow-Current Planetary Mixers. These two types have different focuses in terms of mixing principles and material suitability, meeting the mixing needs of different industrial scenarios.

Counter-Current Planetary Mixer: The inner and outer mixing blades revolve in opposite directions. When the inner blades revolve clockwise, the outer blades revolve counterclockwise simultaneously, creating strong material convection and shear forces. This reverse motion quickly breaks down the agglomerated structure of high-viscosity materials, allowing different components to form a bidirectional circulation within the mixing drum, resulting in higher mixing uniformity. It is particularly suitable for the dispersion and mixing of high-viscosity, high-density materials such as epoxy adhesives and lithium battery slurries.

Flow-Current Planetary Mixer: The inner and outer mixing blades revolve in the same direction. The blade movement trajectories are parallel and orderly, and the material flows in a unidirectional spiral motion within the drum. The overall mixing process is gentler and less likely to damage the original particle morphology of the material. It is more suitable for scenarios where the material morphology is critical, such as mixing jams and creams in the food industry, and mixing ointments and granular preparations in the pharmaceutical field.

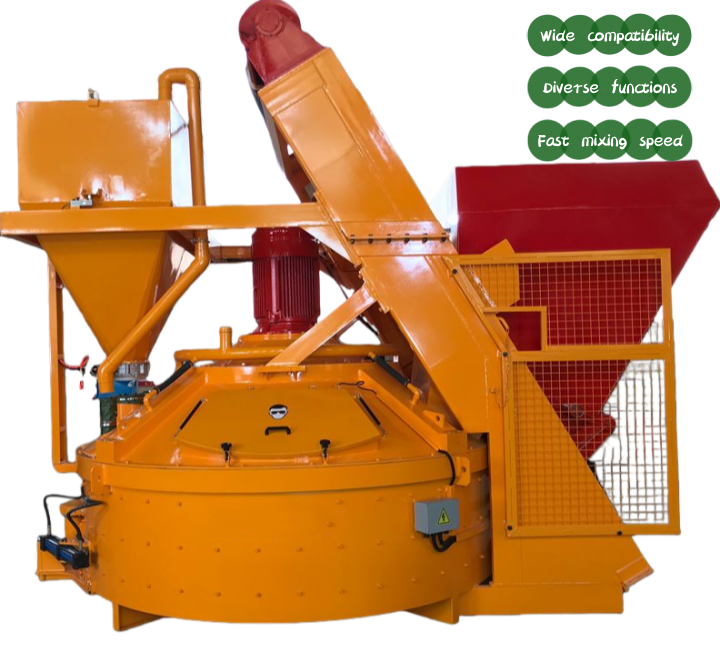

The Current Planetary Mixer has several advantages due to its structure: dead-zone-free mixing ensures stable quality, it supports functional customization and 24/7 operation, offers flexible discharge, and achieves high mixing uniformity and efficiency far exceeding ordinary mixers.

Wide Adaptability: Can handle various material forms including solid-solid, solid-liquid, and liquid-liquid phases, suitable for high-viscosity materials, and allows for the selection of 1-3 discharge gates depending on the production line.

Multifunctional: Mainstream models support customized functions such as vacuum mixing and temperature control: the vacuum system can remove air bubbles from materials, preventing oxidation and deterioration, making it suitable for sensitive materials such as electronic packaging materials and lithium battery raw materials. It can also achieve heating or cooling to meet special process requirements such as reaction and dissolution.

Fast Mixing Speed: The mixing efficiency of the planetary mixer is 3-5 times that of ordinary mixers. When processing high-viscosity materials, the mixing time can be shortened from tens of minutes to 10-15 minutes.

The Current Planetary Mixer consists of core components such as a transmission system, mixing paddle assembly, mixing drum, and discharge device. The transmission system drives the paddles to achieve a combined motion of revolution and rotation. With different functional components, it adapts to the mixing needs of high-viscosity materials in various industries.

Transmission Device: Composed of a high-quality motor from a reputable brand and a patented gearbox. The gearbox has a soft-start option, effectively transmitting power from the motor to the rotating planetary shaft for optimal performance. The gearbox has low noise, suitable for indoor factory settings, and has a high safety factor, meeting the requirements for high torque mixing.

Mixing Device: The planetary shaft with blades installed inside the mixing drum rotates, performing forced mixing through complex actions such as squeezing, shearing, and turning the materials.

Discharge Device: Depending on customer requirements, pneumatic or hydraulic methods can be used to open and close the discharge gate. 1-3 discharge gates can be freely selected, with flexible arrangement and a dedicated sealing device.

Water Supply System: The nozzle uses a spiral solid cone nozzle, providing a fine and uniform atomization effect, achieving excellent uniform water distribution and reducing dust generation.

Safety Device: Includes an emergency stop switch and power-off upon opening the door, preventing unexpected events during operation.

Inspection and Observation Device: The inspection door has an observation port, allowing observation of the mixing process while the mixer is running. The inspection door is equipped with a pneumatic spring assist device for easier opening and closing.

The core working principle of the Current Planetary Mixer lies in the combined motion mode of the mixing blades: revolution + rotation. The motor drives the transmission mechanism, causing the blades to revolve around the central axis of the mixing drum, creating an overall circulation of materials within the drum; simultaneously, the blades rotate rapidly around their own axes, generating strong shear and kneading forces. Their movement trajectory covers the entire mixing drum, achieving thorough mixing without dead zones.

The Current Planetary Mixer has a wide range of applications. Thanks to its thorough mixing capabilities, it empowers various fields such as new energy lithium battery slurries, chemical adhesives, food pastes and fillings, pharmaceutical ointments and gels, and building materials waterproof coatings, meeting the processing needs of high-viscosity materials.

The planetary mixer, with its thorough mixing characteristics through revolution + rotation and its superior adaptability to high-viscosity, multi-component materials, is widely used in critical production processes across multiple fields.

New Energy Industry: It is the core mixing equipment for lithium battery positive and negative electrode slurries and separator adhesives. Vacuum configuration can remove air bubbles from the slurry, ensuring battery energy density and cycle stability.

Chemical Industry: Used for the dispersion and kneading of high-viscosity materials such as sealants, silicone adhesives, and epoxy resins, precisely controlling the uniformity of material mixing and improving product bonding strength.

Building Materials Industry: It can quickly mix materials such as waterproof coatings, tile adhesives, and mortars, solving the problems of uneven mixing and easy stratification in traditional equipment, helping to improve the construction performance and durability of building materials.

3D Printing Materials: It can mix metal powders and binders to form a uniform printing slurry, achieve fine and uniform preparation of ceramic slurries, and gently mix sensitive materials such as bio-inks.

Agricultural Technology: Used for the uniform suspension preparation of pesticide formulations, the precise dispersion of trace elements in fertilizer additives, and the mixing of seed coating materials, improving the uniformity and safety of agricultural products.

| Model | PMC50 | PMC100 | PMC150 | PMC250/td> | PMC330 | PMC500 | PMC750 | PMC1000 | |

| Out Capacity | 50L | 100L | 150L | 250L | 330L | 500L | 750L | 1000L | |

| Input Capacity | 75L | 150L | 225L | 375L | 500L | 700L | 1125L | 1500L | |

| Feeding Weight | 120kg | 240kg | 380kg | 600kg | 800kg | 1200kg | 1800kg | 2400kg | |

| Mixing Power | 3kw | 5.5kw | 7.5kw | 11kw | 15kw | 18.5kw | 30kw | 37kw | |

| Discharge Power | ------ | ------ | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 3kw | |

| Weight | 750kg | 1000kg | 1300kg | 1500kg | 2000kg | 2400kg | 3900kg | 5500kg | |

| Dimension L*W*H mm | 950*790*1200 | 1664*1453*1487 | 1670*1460*1620 | 1860*1650*1780 | 1870*1870*1855 | 2230*2080*1880 | 2580*2340*2195 | 2891*2602*2237 |

| Model | PMC1500 | PMC2000 | PMC2500 | PMC3000/td> | PMC4000 | PMC5000 | |

| Out Capacity | 1250L | 1500L | 2000L | 2500L | 3000L | 4000L | |

| Input Capacity | 1875L | 2250L | 3000L | 3750L | 4500L | 6000L | |

| Feeding Weight | 3600kg | 4800kg | 6000kg | 7200kg | 9600kg | 12000kg | |

| Mixing Power | 55kw | 75kw | 90kw | 110kw | 160kw | 220kw | |

| Discharge Power | 4kw | 4kw | 4kw | 4kw | 4kw | 5.5kw | |

| Weight | 6500kg | 9200kg | 11000kg | 12000kg | 17500kg | 20000kg | |

| Dimension L*W*H mm | 3223*2902*2470 | 3625*3230*2695 | 3893*3550*2875 | 3893*355*3085 | 4594*4150*3634 | 4600*4200*3300 |

The planetary mixer offers a rich selection of configurations, supporting lifting systems, weighing sensors, and dust removal systems. 1-3 discharge doors can be added as needed, and it can be equipped with explosion-proof and intelligent control systems to adapt to the mixing of high-viscosity materials in various industries. Lifting System: When the equipment is being fed, the feeding door automatically opens. When the lifting hopper begins to descend, the feeding door closes. This prevents dust from overflowing from the mixing drum during the mixing process, protecting the environment.

Weighing Sensor: Uses branded tensile or compressive sensors, ensuring stable performance and high weighing accuracy.

Powder Weighing System: The powder weighing system uses weight sensors for weighing, and is equipped with a ventilation device, ensuring high weighing accuracy and strong stability.

Dust Removal System: Optional dedicated dust removal device or pulse back-blowing dust removal device; using dedicated filter elements or fabric bags.

Butterfly Valve: Uses a branded pneumatic rubber-lined butterfly valve with good sealing performance and reliable operation, and outputs open and closed position signals.

Water Metering System: Water metering methods: weighing method, time control method, and flow meter pulse method. High metering accuracy and strong reliability.

The Current Planetary Mixer achieves dead-angle-free mixing through a combination of planetary and rotational motion, suitable for high-viscosity multi-component materials; ordinary mixers have limitations and can only handle low-viscosity simple materials.

Differences in Mixing Principle and Uniformity: The core advantage of the planetary mixer lies in its combined planetary and rotational motion mode. The mixing blades rotate around the center of the mixing drum, achieving dead-angle-free mixing. Ordinary mixers mostly have a single-axis unidirectional rotating structure, relying on the pushing or stirring action of the blades to drive material flow, which easily leads to material stagnation areas on the drum wall and bottom, and is only suitable for mixing low-viscosity, simple-component materials.

Comparison of Material Adaptability: The planetary mixer has extremely strong adaptability and can handle high-viscosity materials. The application range of ordinary mixers is relatively narrow, mostly only suitable for mixing low-viscosity liquids or loose powders. When encountering high-viscosity materials, problems such as high mixing resistance and low mixing efficiency will occur.

Production Efficiency and Energy Consumption: The combined motion of the planetary mixer generates strong shear and convective forces, and the mixing efficiency is 3-5 times that of ordinary mixers. Ordinary mixers require longer mixing times to meet basic mixing requirements, resulting in relatively low production efficiency. Application Scenarios and Cost Differences: Planetary mixers have higher technical barriers and manufacturing costs, making them more suitable for applications requiring high mixing precision and product quality. Conventional mixers, with their simpler structure and lower price, are more suitable for basic processing scenarios where high mixing performance is not critical.

Dahan Machinery's Current Planetary Mixers cover a full capacity range from 50L to 5000L, meeting the needs of various industries including chemical, new energy, food, and pharmaceutical. We build a comprehensive service system centered on our customers, creating a dedicated customer file for each piece of equipment and providing long-term, full-lifecycle tracking services. We strictly adhere to warranty commitments, providing free product operation and maintenance technical training to ensure operators can quickly get started. We also maintain a stable spare parts supply system, providing professional repair services and parts support for the lifetime of the equipment, and promptly responding to all after-sales needs. With customized equipment solutions and attentive after-sales support, we have become a trusted planetary mixer partner for many companies.

The Current Planetary Mixer, with its unique technological advantages, is emerging from traditional mixing equipment to become a key piece of equipment driving industrial upgrading. Its continuous innovation in mixing precision, working condition adaptability, and functional expansion will bring high-speed and stable production solutions to more industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.