Customizable Ribbon Mixer For Detergent Powder Production Line is a core production equipment specially designed for the daily chemical industry. It adopts a double-screw counter-rotating structure, and achieves uniform mixing of multi-component raw materials such as surfactants, enzyme preparations, and flavors through three-dimensional movement of axial convection and radial shear. The mixing uniformity can reach CV≤2.5%, effectively avoiding problems such as agglomeration of washing powder and uneven decontamination. The equipment supports modular customization, and can be equipped with 316L stainless steel, temperature control jacket, explosion-proof system and other components according to production needs, and is suitable for the production of different types of washing powder such as ordinary, concentrated, and special.

Equipped with an intelligent PLC control system, it has precise batching and data traceability functions, and provides 500L-10000L full-specification models to meet the diverse needs from research and development to large-scale production.

Uniform mixing expert for washing powder production lines, modular design to adapt to diverse needs, and intelligent temperature control to ensure quality.

Customizable: Whether it is material, size, height, ribbon, or stirring speed, it can be customized according to your production needs.

Fast mixing cycle: The mixing time of a single batch is 8-15 minutes, which is more than 40% more efficient than the traditional paddle mixer and is suitable for continuous production needs.

Fully open discharge door: Pneumatic/manual discharge valve design, residual amount ≤0.3%, to avoid contamination of formulas between batches.

Accurate liquid addition: The atomizing nozzle evenly sprays flavors or liquid additives (addition accuracy ±1%) to solve the problem of uneven traditional manual addition.

PLC automation system: Store multiple sets of formula parameters (such as ordinary powder/concentrated powder/functional powder), and switch production modes with one button.

Temperature control type: Heating/cooling jacket (-10℃~150℃), suitable for special formulas (such as low-temperature enzyme preparation addition).

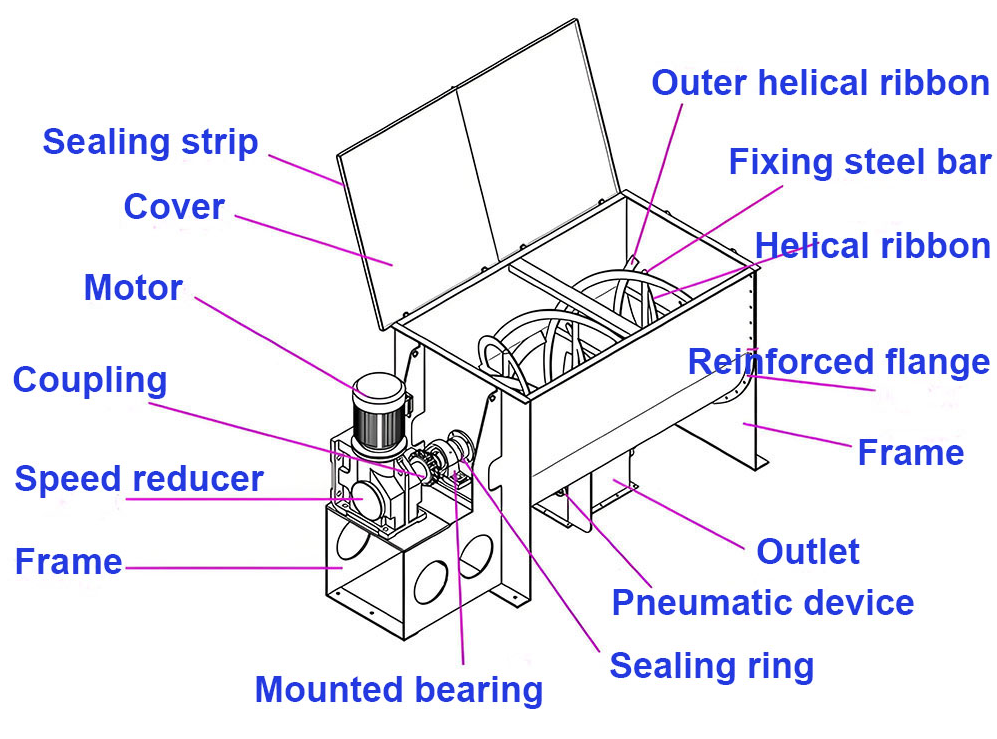

The ribbon mixer adopts a horizontal barrel design with a double-layer ribbon inside, and achieves fast and uniform mixing effect through reverse stirring.

U-shaped container: ensures that the mixed materials (powder, semi-fluid) move with low resistance in the cylinder and improves the mixing efficiency.

Double-layer spiral ribbon: the outer spiral gathers the materials from both sides to the center, and the inner spiral transports the materials from the center to both sides, forming a three-dimensional convection.

Transmission components: the motor and the mixing main shaft are directly connected through a cycloidal pinwheel reducer, which has a simple structure, high operating reliability and convenient maintenance.

Discharging method: the powder material adopts a pneumatic large-opening structure, which has the advantages of fast unloading and no residue; the high-fineness material or semi-fluid material adopts a manual butterfly valve or a pneumatic butterfly valve to meet the discharging requirements of different materials.

In order to meet the specific needs of different washing powder production lines, the spiral ribbon mixer provides a wealth of customization options.

Material selection: carbon steel, 304 stainless steel or 316L stainless steel can be selected according to the characteristics of the material to ensure that the equipment is corrosion-resistant and easy to clean.

Heating/cooling jacket: The jacket is configured to adapt to occasions that require heating or cooling. There are two optional heating methods: electric heating and thermal oil heating; the cooling process can directly inject cooling water into the jacket, the jacket has a large heat exchange area and a fast cooling speed.

Liquid spray system: Liquid additives are sprayed during the mixing process to improve mixing uniformity and product quality.

Vacuum feeding: Designed as a vacuum operation, vacuum suction is achieved to improve production efficiency.

Automatic control: Equipped with a PLC control system to achieve automated production and reduce labor costs.

Explosion-proof motor: For flammable and explosive materials, explosion-proof motors can be selected to ensure production safety.

Covering ordinary/concentrated/special laundry detergents, the actual measured uniformity is high and the agglomeration rate is reduced by 81%.

Ordinary laundry powder: mixing time 8-12 minutes, uniformity ≤2.5%, particle qualification rate ≥95%;

Concentrated laundry powder: through high shear ribbon edge, the additive microencapsulation is realized, and the detergency is improved by 30%;

Infant special laundry powder: aseptic design (CIP online cleaning + UV sterilization), microbial control ≤50CFU/g, in line with GB 19102-2013 standard.

As a manufacturer of powder mixing equipment for more than ten years, Dahan Machinery has become a leading supplier of ribbon mixers in the laundry powder industry. We use precision technology to manufacture 316L stainless steel/wear-resistant alloy steel equipment (lifetime 100,000 hours+), support 500L-10 tons full range customization (including special configurations such as explosion-proof/temperature control), and have provided intelligent mixing solutions for many companies, and ensured 100% factory qualification rate through 72 hours of rigorous testing. If you are shopping, you might as well learn about us!

Customizable ribbon mixers for washing powder production lines play an important role in washing powder production with their advantages of efficient mixing, low residue design, stable and durable, and flexible adaptation. By selecting the appropriate specifications and customized options, it can meet the needs of different production scales and improve product quality and production efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.