Feed Pellet Vertical Mixer is a vertical mixing equipment designed for livestock and poultry feed, aquatic feed, and premixes. It adopts a single spiral lifting + diffusion plate structure to achieve rapid circulation mixing. It is suitable for uniform mixing of particles, powders and trace additives, and can be better used in some feed pellet mixing scenarios with limited site range.

The feed pellet vertical mixer uses its own structural characteristics to bring the following advantages to mixed feed pellet manufacturers.

Structural advantages: The vertical design occupies a small area and is more suitable for feed factories with space restrictions.

Low energy consumption: Compared with horizontal mixers, its energy consumption is 30-50% lower.

Fast cycle: 5-10 minutes/batch, 20% more efficient than horizontal models

Three-dimensional compound motion: The dual effects of spiral lifting + gravity diffusion realize axial and radial synchronous mixing.

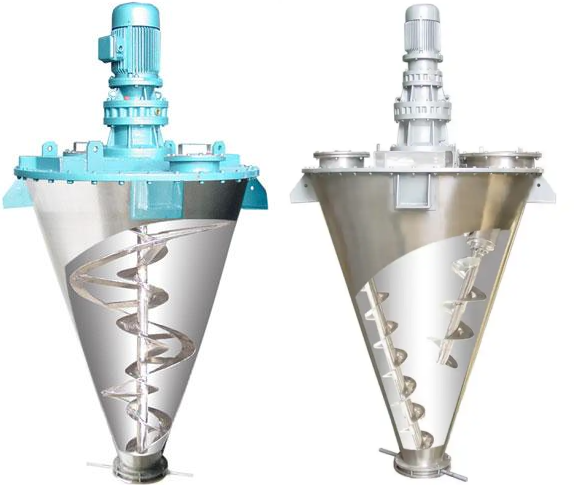

The stirring shafts we provide for feed pellet vertical mixers are divided into single spiral and double spiral.

Single screw shaft (basic type): It adopts a single vertical screw shaft with a pitch of 300-500mm. It is easy to maintain and its cost is 30% lower than that of the double-shaft model. It is suitable for mixing ordinary pellet feeds and is often used for mixing poultry and livestock feeds in small and medium-sized farms and preparing basic raw materials such as corn and soybean meal.

Double screw shaft (high-efficiency type): It is equipped with two parallel screw shafts, which can rotate in the same or opposite direction, with a speed of 20-40rpm and a power 40% higher than that of a single shaft. It can achieve high uniformity mixing with CV≤5%, and it is not easy to agglomerate when processing sticky feeds such as fish oil. It has an adjustable pitch and a shaft end leak-proof design, and is widely used in aquatic feeds containing more than 8% oil.

The feed pellet vertical mixer, with customized configuration, can accurately meet the mixing needs of different feed types such as livestock, poultry, and aquatic products!

Livestock and poultry feed: Suitable for mixing corn, soybean meal and other pellets with powder. It can evenly mix grains, bran and premixes of different particle sizes to meet the nutritional needs of pigs, chickens and other livestock and poultry, ensure the balanced distribution of various ingredients in the feed, and help livestock and poultry grow healthily.

Aquatic feed: Especially suitable for mixing high-fat formulas, it can effectively evenly blend fish oil, vegetable oil, etc. with an addition amount of ≤8% into feed particles, while avoiding feed agglomeration caused by oil accumulation, ensuring that aquatic animals obtain sufficient energy and nutrition when feeding.

Premix: It can achieve uniform distribution of trace ingredients such as vitamins and minerals, and the mixing uniformity reaches CV≤5%, ensuring that the content of trace elements in each premix is consistent, providing a precise nutritional basis for livestock and poultry feed production.

Functional feed: Suitable for mixing heat-sensitive ingredients such as probiotics and enzyme preparations. Through gentle stirring, high temperature is avoided to destroy the active ingredients, ensuring the effectiveness of functional ingredients in feed, and enhancing the promotion of feed to animal digestion and absorption.

| Model | Total volume(L) | Capacity(kg) | Mixing time(Minutes) | Power(kw) | Total height(m) | Weight(kg) | |

| CF-DSH-1 | 1000 | 400-600 | 5-10 | 4 | 2775 | 1200 | |

| CF-DSH-2 | 2000 | 800-1200 | 5-10 | 5.5 | 3424 | 1500 | |

| CF-DSH-6 | 6000 | 2400-3600 | 5-10 | 15 | 4960 | 3500 | |

| CF-DSH-8 | 8000 | 3200-4800 | 5-10 | 18.5 | 5378 | 4000 | |

| CF-DSH-10 | 10000 | 4000-6000 | 5-10 | 18.5 | 5678 | 4300 | |

| CF-DSH-12 | 12000 | 4800-7200 | 5-10 | 22 | 6015 | 4500 | |

| CF-DSH-15 | 15000 | 6000-9000 | 5-10 | 30 | 6650 | 5000 | |

| CF-DSH-20 | 20000 | 8000-12000 | 5-10 | 37 | 7176 | 6000 |

The vertical mixer for feed pellets is based on a vertical barrel with a built-in spiral conveyor. When working, the material enters from the bottom of the barrel, and the spiral blade lifts it up to the top, then spreads it around through the throwing port, and falls back to the bottom along the barrel wall under the action of gravity. In this process, the guide plate guides the material to form a circular convection, and with the repeated lifting and throwing of the spiral, feed pellets and powders of different particle sizes and densities are evenly mixed in the circulation motion.

As the source manufacturer of mixing equipment, we have customers from different users and different industries. The following is their feedback.

Case 1: Small aquaculture farm: Expect to build a set of shrimp sinking pellet feed production equipment with an hourly output of 200kg. The vertical mixer is equipped with a small footprint and convenient operation, and a batch of materials can be mixed in just 15 minutes.

Case 2: Family farmers: Need a small equipment with a daily output of about two tons of pellet feed. According to the customer's site size and financial budget, a vertical flat die pellet machine is recommended, in which an integrated feed machine is used for material crushing and mixing in the mixing process. This vertical crushing and mixing integrated machine is suitable for crushing, mixing and mixing of various granular crops, with the advantages of high production efficiency, small footprint, time-saving and labor-saving operation, and affordable price.

We provide vertical feed pellet mixers of different models, materials, and mixing shafts. We have a professional team that can recommend the appropriate model of mixer for you according to your site conditions and needs. In addition, our equipment also supports non-standard customization, providing you with one-to-one professional services!

Feed pellet vertical mixers have become the first choice for small and medium-sized feed factories with their economical and efficient characteristics, especially suitable for mixing granular materials with good fluidity and small density difference.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.