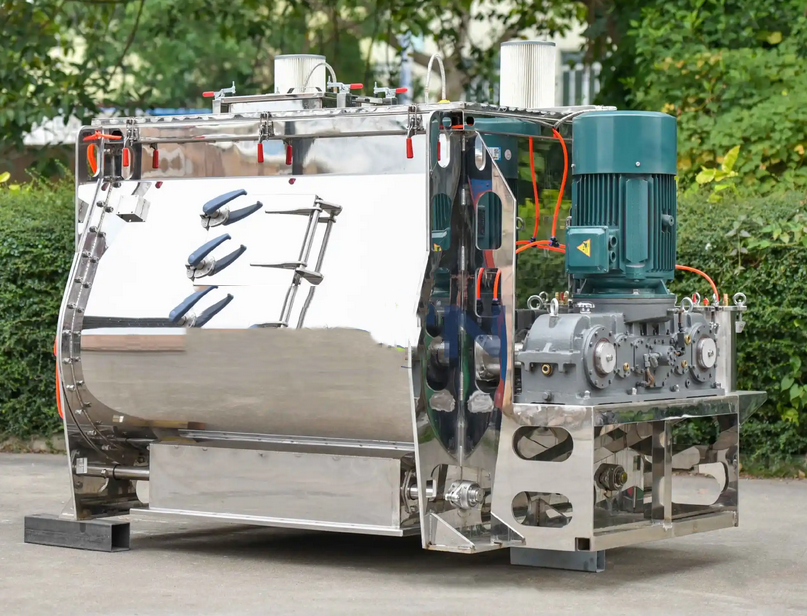

Heavy-Duty Ribbon Blender For Ceramic Powder And Glaze Mixing is specially designed for mixing ceramic powder and glaze. It adopts wear-resistant double-screw structure and optional ceramic lining to achieve high uniformity mixing. It supports 500L-10 tons capacity and -30℃~300℃ temperature control. It is equipped with intelligent PLC system, which is 40% more efficient than traditional equipment. It has been successfully applied to electronic ceramics, building glazes and other fields. It provides explosion-proof/aseptic customization and free trial service. It is an ideal choice for efficient production in the ceramic industry.

High-efficiency mixing expert! The heavy-duty ribbon mixer is specially designed for ceramic powder and glaze. It is 40% more efficient than traditional equipment. It has successfully served high-end fields such as electronic ceramics and building glazes!

Fast mixing: The double-screw belt rotates in reverse to achieve three-dimensional compound motion (axial + radial + convection), and the mixing time is shortened by 40% compared with traditional equipment.

Wear-resistant design: The mixing blades are lined with high-chromium alloy steel or ceramic, and the wear resistance life is increased by 3. Large-capacity processing: single batch capacity is 500L-10 tons, which meets the needs of industrial continuous production.

Precise temperature control: optional heating/cooling jacket (temperature range 5℃-200℃), suitable for glaze reaction or heat-sensitive materials.

Intelligent control: PLC+touch screen operation, support recipe storage, data recording, fault alarm, and realize automated production.

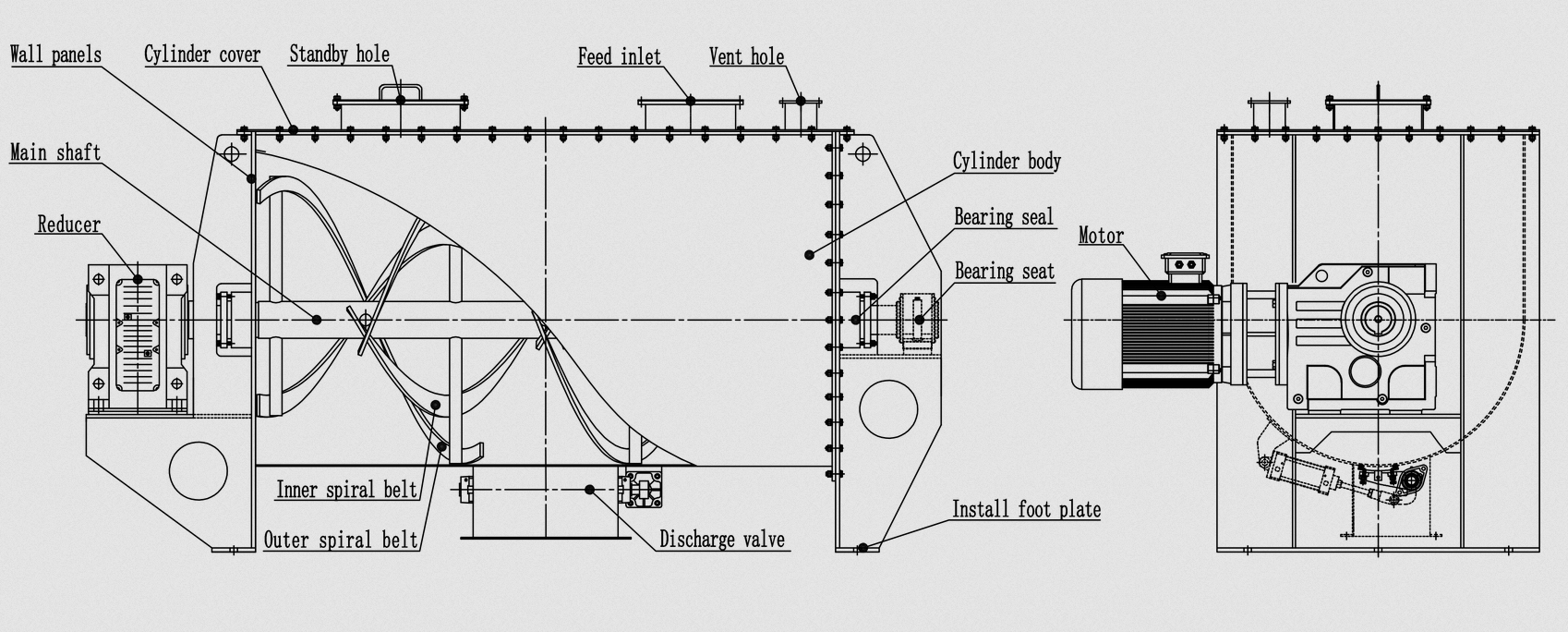

Usually includes core parts such as transmission device, stirring device, stirring cylinder, unloading mechanism, sealing and support components.

Transmission device: generally composed of electric motor, reducer, coupling, etc., to provide power for the mixer.

Stirring device: There are two layers of inner and outer spiral ribbons on the stirring shaft. The inner spiral transports the material to the outside, and the outer spiral gathers the material to the inside. The material can be evenly mixed in a short time under the convection motion of the double-layer spiral ribbon.

Mixing cylinder: generally a U-shaped horizontal cylinder, this structure is compact and reasonable, runs smoothly, has reliable quality, low noise and long service life.

Discharging mechanism: a discharge port is opened at the bottom of the horizontal cylinder of the mixer, and the spiral structure of the outer spiral belt cooperates with the rotation direction of the main shaft to drive the material inside the cylinder wall to the discharge port for discharge.

The heavy-duty ribbon blender uses a double-screw convection mixing mechanism (the outer right-handed spiral pushes the material to the center, and the inner left-handed spiral conveys the material in reverse to form a three-dimensional cycle) and high-intensity shear force to effectively break ceramic powder agglomerates and eliminate the stratification phenomenon caused by density differences. It combines variable frequency speed regulation and temperature control to achieve adaptive adjustment of process parameters. At the same time, the scraper device and continuous discharging process control the residue to 0.5%-1%. Finally, it shortens the mixing time by 60%-80%, reduces energy consumption by 30%-40%, and ensures the uniformity of CV value ≤5%, becoming the core equipment for mixing ceramic powder and glaze that takes into account efficiency, precision and low residue.

The heavy-duty ribbon blender is designed for the ceramic industry and is suitable for efficient mixing of ceramic powders such as alumina and zirconia, as well as glazes such as frit glaze and raw glaze, with a uniformity of CV≤3%

Ceramic powder premixing: The heavy-duty ribbon blender can adapt to the mixing needs of materials with different viscosities through the frequency conversion speed regulation function to ensure the fluidity and dispersibility of the powder.

Glaze modulation: Glaze formulas often contain high-density minerals and low-density fluxes, and traditional equipment is prone to stratification. The ribbon blender achieves uniform mixing of light and heavy powders through the synergistic effect of gravity diffusion and forced stirring, ensuring the gloss and flatness of the glaze after firing.

Powder-liquid mixing: In the preparation of ceramic colorants, metal oxide powders need to be mixed with organic solvents. The equipment supports a liquid spray atomization device, which can achieve instantaneous and uniform adsorption of droplets and powders to avoid local agglomeration.

The heavy-duty ribbon blender for ceramics uses 316L stainless steel + tungsten carbide wear-resistant spiral ribbon, which is specially designed for high-hardness ceramic powder and glaze, solving the industry pain points of fast wear and high residue of traditional equipment!

Anti-sticking design: In view of the strong viscosity and easy adhesion of ceramic raw materials, mirror polishing is adopted, combined with auxiliary scraping device to ensure that there is no material residue on the cylinder wall.

Wear-resistant reinforcement: Tungsten carbide alloy strips are inlaid on the edge of the spiral ribbon to greatly improve the wear resistance; the wearing parts adopt a quick-release structure, and the replacement time is shortened to less than 30 minutes.

High-precision mixing control unit: equipped with a torque monitoring system, automatic alarm when exceeding the set value of ±5%, to ensure mixing stability; optional high-precision weighing module to achieve accurate ratio.

Three-dimensional motion optimization design: innovative double-screw structure achieves efficient convection, outer screw linear speed 0.8-1.2m/s, inner and outer screw speed ratio 1:1.25, drives the material to circulate 8-12 times per minute, forming axial and radial composite motion.

Anti-stratification and intelligent control technology: adjustable baffle with pulse stirring mode to effectively break the material stratification; central airflow distributor assists material dispersion to ensure uniform fusion of ceramic powder and glaze.

|

Comparison Items |

Heavy-duty Ribbon Mixer |

Ordinary Ribbon Mixer |

|

Structural Strength |

12-20mm thick steel plate frame, 300% enhanced anti-deformation capability |

6-10mm thin plate structure |

|

Maximum Loading Density |

1.8g/cm³ |

1.0g/cm³ |

|

Motor Power |

11-75kW |

3-22kW |

|

Continuous Working Hours |

24-hour non-stop operation |

≤8 hours/day |

|

Temperature Control Range |

-30℃~300℃ (optional heating/cooling jacket) |

Ambient temperature (no temperature control) |

|

Applicable Materials |

High hardness (Mohs ≥6), high viscosity (≥50,000cP) |

Lightweight powders (density ≤1.0g/cm³) |

|

Corrosive Environment Resistance |

Resistant to pH 1-14 |

Limited to conventional environments |

Dahan Machinery has been deeply involved in the field of ceramic equipment for more than ten years, focusing on the research and development of high-performance heavy-duty ribbon blenders. With double-screw ribbon convection mixing, high-precision shear crushing and intelligent process control as core technologies, it achieves low residue, high uniformity and energy consumption optimization of material mixing. It widely serves high-end fields such as alumina ceramics and daily porcelain glazes, providing full-process solutions from material customization to vacuum temperature control. With the cooperation experience of 200+ leading companies and a global service system, it continues to empower and increase efficiency for global ceramic companies, and is a trustworthy expert partner in the field of powder mixing.

Heavy-duty ribbon blenders have become an ideal choice for mixing ceramic powders and glazes with their core advantages of high efficiency, precision and low energy consumption. Whether it is the high-purity premixing of alumina ceramic substrates or the complex modulation of glaze formulas, this equipment can provide stable and reliable solutions

Address:China,Yanjin county forest park gate to the west 1000 meters north road.