High-Speed Ribbon Mixer For Pharmaceutical Powder Homogenization is specially designed for drug production. The high-speed ribbon mixer realizes three-dimensional convection with a double helix structure. With strong shear force and precise speed control, it can evenly disperse trace APIs such as antibiotics and vitamins to 0.1%, and the mixing uniformity CV value is stable ≤2%. The fully enclosed 316L stainless steel material is equipped with a CIP cleaning system, strictly abides by GMP standards, and eliminates cross contamination. From small trials of innovative drugs to solid dosage production, from sterile biologics to highly active anticancer drugs, modular customization meets the needs of multiple scenarios and builds a solid defense line for drug efficacy stability and production compliance.

The double helix structure drives three-dimensional convection, the fully enclosed aseptic design, and modular customization adapt to multiple scenarios, from research and development to mass production, empowering both drug quality and production efficiency.

Ultra-high uniformity: suitable for precise dispersion of trace active ingredients, with a mixing ratio as low as 1:100,000 and a stable CV value of ≤3%.

Pollution-free design: fully enclosed structure to avoid external contamination. Optional CIP/SIP cleaning system to meet aseptic production requirements.

Intelligent control: PLC+touch screen control, storage of 50+ mixing process parameters. Real-time monitoring of temperature, speed, mixing time, and data traceability.

Low residue and efficient unloading: bottom fully open unloading valve (pneumatic/electric/hydraulic), residue <0.1%. Special ribbon design, no "dead zone", to avoid cross contamination.

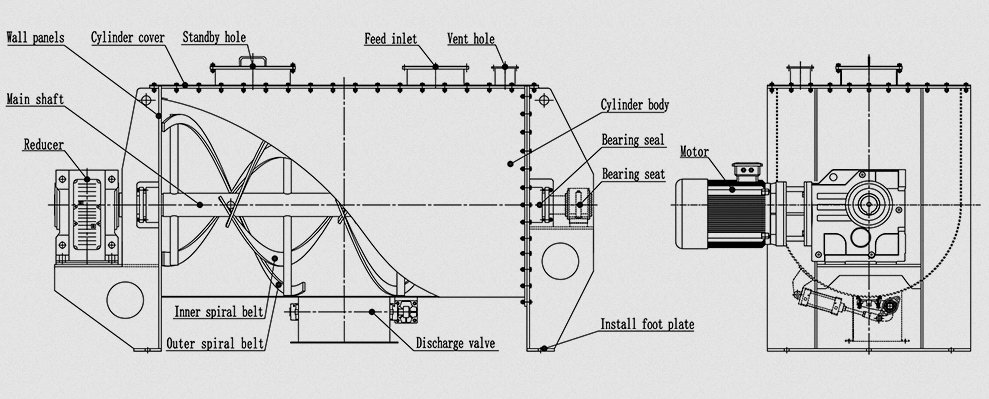

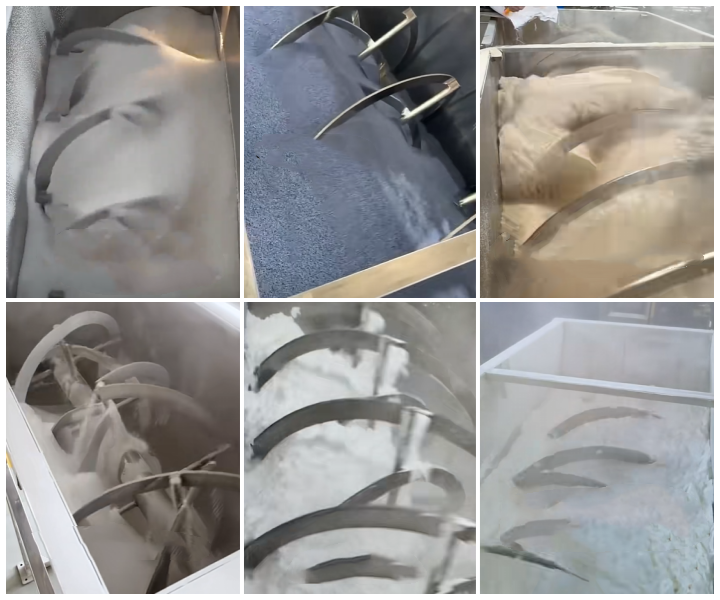

The high-speed ribbon mixer achieves drug powder homogenization through a double helix structure in a U-shaped cylinder. The inner and outer layers of the reverse spiral ribbon rotate at high speed, generating strong shear force and convection, so that the material forms a three-dimensional circulation movement in the cylinder, quickly breaks up the agglomerated particles, and promotes the uniform distribution of materials of different densities and particle sizes. The mixing uniformity CV value can reach ≤2%.

In the pharmaceutical field, the accuracy and uniformity of material mixing are directly related to the quality and efficacy of drugs. With its excellent mixing performance, the high-speed spiral ribbon mixer is deeply adapted to a variety of materials such as APIs, excipients and granules.

APIs: The mixing of trace ingredients such as antibiotics and hormones must ensure that they are evenly dispersed in the carrier to avoid affecting the efficacy due to excessive or low local concentrations.

Excipients: Excipients such as lactose, microcrystalline cellulose, and starch are indispensable components in the pharmaceutical process, and their homogenization degree directly affects the formability and stability of the drug.

Granules: The final mixing of granules and tablets is a key link in drug production, which directly affects the disintegration time and dissolution of the drug. High-speed ribbon mixer can evenly blend a variety of main drug particles with auxiliary material particles to ensure the consistency of the ingredients of each bag of powder

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Under the refined and standardized production requirements of the pharmaceutical industry, high-speed ribbon mixers are deeply integrated into multiple core application scenarios with their efficient homogenization and flexible adaptation characteristics, becoming a key equipment to ensure drug quality and production efficiency.

Solid preparation production: High-speed ribbon mixers can quickly mix a variety of raw materials such as main drugs, fillers, disintegrants, lubricants, etc. with their powerful convection and shear capabilities.

Innovative drug research and development: The small-capacity model of the high-speed ribbon mixer just meets this demand. Its modular design supports rapid disassembly and cleaning, which is convenient for switching between different formulation experiments to avoid material residues interfering with experimental results.

CMO/CDMO companies: Companies undertake commissioned production tasks of multiple varieties and small batches, and have extremely strict requirements on the versatility, flexibility and compliance of equipment. High-speed ribbon mixers have become an ideal choice for CMO/CDMO companies with their flexible customization capabilities. It can be customized with 316L stainless steel, electrolytically polished inner wall, explosion-proof device and other configurations according to the characteristics of different customers' drugs to meet the mixing needs of flammable and explosive ingredients or highly active drugs.

Aseptic powder processing: In the mixing process of sterile powders such as anti-tumor drugs and biological agents, preventing cross-contamination and microbial contamination is of paramount importance. The high-speed ribbon mixer adopts a fully enclosed design, with online cleaning and online sterilization system, which can complete deep cleaning and sterilization without disassembling the equipment to ensure that the inside of the equipment is sterile.

The factors affecting the mixing uniformity of the high-speed ribbon mixer mainly involve equipment design, process parameters and material characteristics. The following is a specific analysis.

Equipment core structure influence: The ribbon configuration, barrel size and stirring speed of the high-speed ribbon mixer directly determine the mixing effect. Improper design of the ribbon pitch, diameter and rotation direction can easily cause excessive shearing or low efficiency; mismatch of barrel length-width ratio and ribbon coverage will cause material retention.

Key role of process parameters: mixing time, loading amount and feeding order are the key points of process control. It is necessary to grasp the optimal mixing cycle to avoid short undermixing or long stratification; the loading amount is controlled at 30% - 70% of the volume to ensure material flow; follow the "light first, heavy later" feeding order.

Material property adaptation requirements: the material's own characteristics significantly affect the mixing uniformity. Large differences in particle size and density are easy to segregate, and pretreatment is required for improvement; hygroscopic and sticky materials are easy to agglomerate and adhere, and need to be matched with drying or anti-sticking design; materials with poor fluidity rely on strong shear force to disperse, otherwise they are prone to local accumulation.

For different materials such as APIs, excipients, granules, etc., the mixing time varies significantly.

Highly active drugs: Mixing takes 20-40 minutes. By extending the mixing time, the trace API is ensured to be evenly dispersed (CV≤3%). At the same time, low-speed operation reduces the risk of static electricity, and adapts to the strict safety requirements of high-risk ingredients such as anti-tumor drugs.

Inhalation powder aerosol: Use airflow-assisted mode to mix for 10-20 minutes to solve the problem of particle size difference between lactose carrier (80μm) and API (1-5μm), avoid fine powder agglomeration, and meet the dispersion uniformity standard of pulmonary drug delivery preparations.

Segmented processing of Chinese medicine compound powder: It takes 12-25 minutes of intermittent mixing. For components with large density differences such as mineral drugs and plant extracts, segmented feeding and variable speed stirring are used to achieve homogenization, ensuring the quality stability of traditional compound preparations.

As a professional ribbon mixer manufacturer, Dahan Machinery's products cover a full range of 316L stainless steel models from 5 to 2000L. It uses a patented double-ribbon design to achieve precision mixing of CV≤3% (supports 1:100,000 micro-dispersion), and is equipped with an intelligent control system and CIP/SIP cleaning function. It has provided a complete solution covering equipment, validation documents and lifelong services for more than 300 pharmaceutical companies around the world (including TOP10 multinational pharmaceutical companies), especially for the high-standard mixing needs of highly active drugs, APIs and excipients.

High-speed ribbon mixers play an irreplaceable role in the homogenization of pharmaceutical powders. Through efficient mixing functions and the advantages of meeting hygiene standards, they provide reliable mixing solutions for the pharmaceutical industry. Customized mixers will provide customers with more choices and promote the development and progress of the pharmaceutical production industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.