Horizontal Shaft Ribbon Mixer for Cattle Feed uses a horizontally shaft-driven spiral ribbon as its mixing core. It is suitable for the uniform mixing of multiple components in cattle feed, including concentrates, roughage, additives, and minerals. Utilizing the counter-current convection motion of the double spiral ribbon, it thoroughly mixes and blends cattle feed materials of different specific gravities and particle sizes, effectively preventing stratification. It is suitable for mixing silage, straw meal, soybean meal, cornmeal, and other cattle feed ingredients.

The Horizontal Shaft Ribbon Mixer for Cattle Feed supports non-standard customization, allowing you to adjust the machine size and change the shape and size of the inlet and outlet to meet your needs. It also supports various configuration requirements, including the addition of moving rollers, spray systems, and intelligent control systems, ensuring various mixing needs are met during the mixing process.

The Horizontal Shaft Ribbon Mixer for Cattle Feed is suitable for processing various cattle feeds, including concentrates, roughage, and daily rations, boasting core advantages such as high mixing uniformity, strong material adaptability, and low residue.

High mixing uniformity: The dual-ribbon counter-current convection mixing system thoroughly mixes and blends cattle feeds of different proportions and particle sizes, including concentrates, roughage, additives, and minerals, effectively preventing material stratification.

Suitable for various cattle feeds: Designed for common cattle feed ingredients such as silage, straw powder, soybean meal, corn flour, and distillers' grains, the mixing force is moderate, neither breaking roughage fibers nor failing to evenly disperse trace additives.

Suitable for large-scale farming: The horizontal shaft ribbon mixer creates a bidirectional vortex, significantly shortening the mixing cycle. Single batch processing capacities range from hundreds of kilograms to tens of tons.

Low residue: The U-shaped cylinder conforms to the ribbon mixing trajectory, with a smooth inner wall and no dead corners. Precise control of the gap between the ribbon and the cylinder wall ensures complete material discharge.

Easy operation: Supports variable frequency speed control, allowing adjustment of the mixing speed according to material characteristics; equipped with a convenient discharge valve for simple unloading; modular design for easy disassembly and cleaning.

The Horizontal Shaft Ribbon Mixer for Cattle Feed is available in two main types based on ribbon configuration: single ribbon and double ribbon. Both are suitable for multi-component mixing needs of cattle feed. The core differences lie in the mixing structure, mixing efficiency, and applicable scenarios, precisely matching the production needs of different farming scales.

Single-Screw Ribbon Mixer for Cattle Feed: Utilizing a single-unit continuous spiral belt mixing structure, the horizontal shaft drives the feed in a circular motion, conveying and mixing the feed from one end of the drum to the other. It features a simple structure, low energy consumption, gentle mixing force, and minimal breakage of roughage fibers such as straw and silage. Suitable for small to medium-sized cattle farms requiring small-batch, low-frequency cattle feed mixing.

Double-Screw Ribbon Mixer for Cattle Feed: Equipped with a double-layer counter-rotating spiral belt, the outer layer gathers the feed from both sides towards the center of the drum, while the inner layer pushes the material outwards in the opposite direction, creating a bidirectional convection vortex. This ensures thorough mixing of concentrates, roughage, and trace additives, resulting in a more uniform and thorough blend. Suitable for large-scale, continuous cattle feed production needs in cattle farms and feed processing plants.

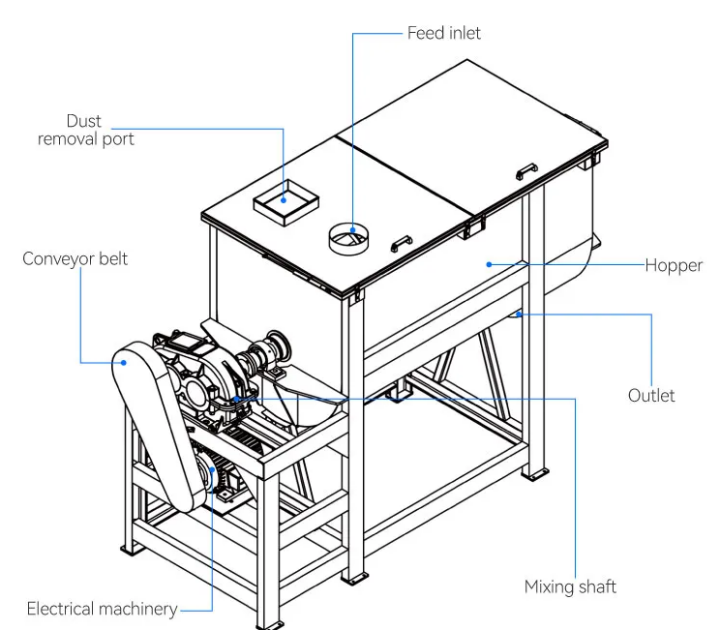

The horizontal shaft belt mixer for cattle feed is a horizontal integrated structure, consisting of four core parts: the main drum, the horizontal shaft mixing system, the transmission drive system, and the unloading control system.

Main Unit: Constructed of thickened carbon steel and stainless steel, its classic U-shaped design conforms to the mixing trajectory, eliminating dead corners and preventing material buildup. The unit wall undergoes wear-resistant and rust-proofing treatment, withstanding friction from coarse and hard raw materials such as straw and distiller's grains.

Horizontal Shaft Mixing System: The core of this system is a horizontal through-shaft mixer paired with a ribbon mixing assembly. The gap between the ribbon and the unit wall is precisely controlled. Wear-resistant bushings are fitted at both ends of the mixing shaft, ensuring effective mixing while preventing wear from hard friction.

Transmission Drive System: Composed of a motor, reducer, coupling, and sealing cover. The motor is typically a frequency converter, allowing for adjustable mixing speed. The reducer is equipped with high torque output to meet the power requirements for mixing roughage. The transmission components undergo double-layer sealing to prevent feed dust and moisture ingress.

Unloading Control System: An arc-shaped discharge port is located at the bottom of the unit, paired with manual/pneumatic discharge valves. The valves fit snugly against the arc of the tank bottom, ensuring thorough and residue-free unloading. The pneumatic version can be linked for control, adapting to automated production lines.

The Horizontal Shaft Ribbon Mixer for Cattle Feed features a horizontal cylindrical structure with multiple layers of counter-rotating spiral belts inside. During operation, the main motor drives the spiral belt shaft to rotate via a reducer. The outer spiral belt pushes the material from both ends towards the center, while the inner spiral belt conveys the material in the opposite direction, creating a high-intensity convection circulation. The material simultaneously undergoes radial, axial, and tangential combined motions in three-dimensional space, achieving uniform mixing of roughage and concentrate under shearing and diffusion effects.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The Horizontal Shaft Ribbon Mixer for Cattle Feed is highly adaptable, capable of mixing all types of cattle feed, including concentrates such as cornmeal and soybean meal, roughage such as straw meal and silage, and can also mix trace additives, byproducts, and wet feed containing liquid.

Fine Feeds: Suitable for mixing with powdered and granular concentrates such as cornmeal, soybean meal, wheat bran, rice bran, and rapeseed cake. The spiral mixing mechanism ensures uniform blending of different protein and energy-producing concentrates.

Roughage Feeds:Compatible with straw powder, silage, yellow silage, peanut vine powder, and hay powder. The gentle mixing prevents damage to the coarse fiber structure, meeting the feed requirements for ruminant digestion in cattle.

Total Mixed Rations:Enables precise blending of concentrates and roughages, while also being compatible with by-products such as distiller's grains, soybean residue, and beet pulp, providing a one-stop solution for mixing complete cattle rations.

Additive-Based Compound Feeds:Thoroughly mixes trace elements, vitamins, amino acids, mold inhibitors, probiotics, and other micronutrient additives with the base feed, preventing localized additive aggregation.

Wet/Semi-Wet Feeds: Can be mixed with wet or semi-wet feeds containing water, syrup, and oil. The spiral mixing mechanism ensures thorough blending of liquid and dry feeds without dead zones or residue buildup.

Our factory offers two main material options for the Horizontal Shaft Ribbon Mixer for Cattle Feed: carbon steel and stainless steel. The choice depends on the scale of the farm, the type of feed, and the operating conditions, balancing practicality and cost control. The carbon steel material is thickened and wear-resistant, treated with rust-proof paint. It boasts high hardness and impact resistance, withstanding friction from coarse feeds such as straw and distiller's grains. It also offers lower procurement and maintenance costs, suitable for the basic needs of small to medium-sized cattle farms mixing regular dry feed and roughage.

The stainless steel material is made of food-grade stainless steel. Its smooth, corner-free inner wall is corrosion-resistant and prevents feed residue buildup. It is easy to clean and avoids feed contamination. It is suitable for mixing wet feeds containing moisture, acids, or alkalis, as well as waste feeds, or for large-scale farms and feed processing plants with high hygiene standards.

The batch mixing time of the Horizontal Shaft Ribbon Mixer for Cattle Feed varies slightly depending on the ribbon type, material ratio, and batch capacity, but typically ranges from 3 to 20 minutes. Single-ribbon models are suitable for small-batch mixing of dry and roughage, achieving uniform mixing in 3-20 minutes. Double-ribbon models, with their bidirectional convection vortex design, offer even higher mixing efficiency; even for large-batch mixing of blended concentrates and roughage, high uniformity can be achieved in just 5-20 minutes, without damaging the roughage fiber structure throughout the process.

Dahan Machinery manufactures Horizontal Shaft Ribbon Mixers for Cattle Feed, which can be customized with carbon steel or stainless steel materials. The entire machine is manufactured in strict accordance with industry standards, with a comprehensive quality control system to ensure durability and mixing stability. Supporting customized designs, equipment parameters and configurations can be adjusted according to the scale of farming and production conditions. Factory trial runs, debugging guidance, and after-sales spare parts services are also provided. The products cover large, medium, and small cattle farms and feed processing plants, and have gained long-term recognition from farmers across the country due to their high cost-effectiveness and comprehensive service.

The Horizontal Shaft Ribbon Mixer for Cattle Feed, as a key piece of equipment for modern large-scale farm production, has become a core tool for improving feed nutritional uniformity and reducing farming costs due to its rapid mixing performance and stable operation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.