Industrial Powder Ribbon Mixer For Chemical Raw Materials Mixing is an industrial-grade ribbon mixer specially developed for mixing chemical raw materials. The bidirectional ribbon design ensures more than 99% mixing uniformity. The equipment supports 3-15 minutes of rapid mixing, and optional explosion-proof, nitrogen protection, heating/cooling jackets and other configurations to meet the stringent working conditions of lithium battery materials, pesticide powders, pharmaceutical intermediates, etc. It adopts PLC intelligent control, has formula storage and real-time monitoring functions, and the mixing efficiency is 40% higher than that of traditional equipment!

It provides carbon steel and stainless steel options. Both materials support explosion-proof, heating and other customization to meet the needs of different industries.

Carbon steel ribbon mixer: Focusing on the mixing of non-corrosive, non-food-grade chemical raw materials, it is suitable for materials such as mineral powders and fertilizers, and is suitable for building materials metallurgical drying conditions. With the carbon steel substrate and wear-resistant and load-bearing characteristics, a single batch can process 1-10 tons of materials, and the price is 30%-50% lower than stainless steel.

Stainless steel ribbon mixer: specially designed for high-cleanliness or strong corrosion scenarios such as food, medicine, and fine chemicals, suitable for materials such as lithium battery materials and pharmaceutical intermediates. Made of 304/316L stainless steel, the surface is mirror polished and easy to clean.

The bidirectional ribbon design achieves 99% high uniform mixing and quickly completes batch processing in 3-15 minutes. It is an ideal choice for industries such as fine chemicals and medicine.

Professional chemical grade configuration: The contact parts are made of 316L stainless steel, and acid-resistant and alkali-resistant coatings or Hastelloy alloy materials are optional.

Low wear and low residue design: The gap between the edge of the ribbon and the cylinder is controlled at 0.5-1mm, and wear-resistant surfacing technology is adopted to reduce material wear; the bottom of the U-shaped cylinder is tilted and equipped with a pneumatic butterfly valve, and the discharge residue is <0.1%, which is suitable for mixing high-value chemical raw materials.

Multifunctional expandability: can be integrated with heating/cooling jacket (thermal oil temperature control range - 30℃~200℃), spray liquid addition system and vacuum degassing device to meet the complex process requirements such as chemical reaction mixing and wet granulation.

Professional chemical safety design: the equipment is specially designed for the chemical industry, equipped with a fully enclosed structure and nitrogen protection interface to meet the explosion-proof requirements of flammable and explosive materials.

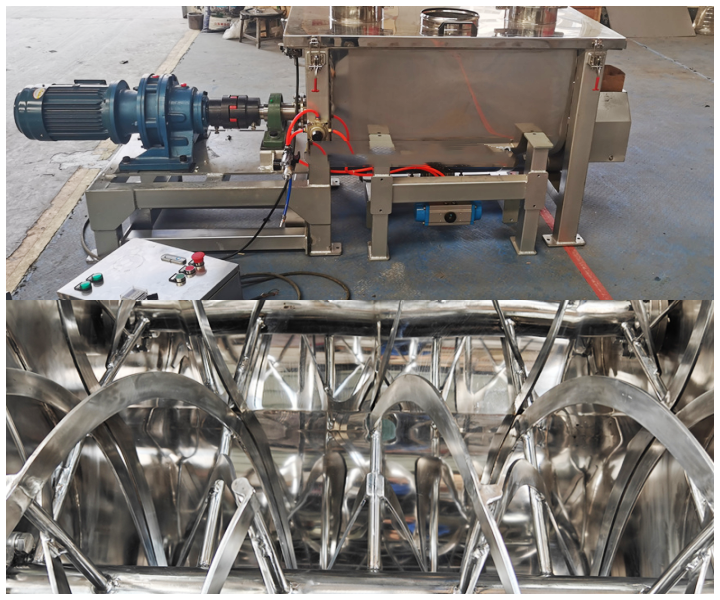

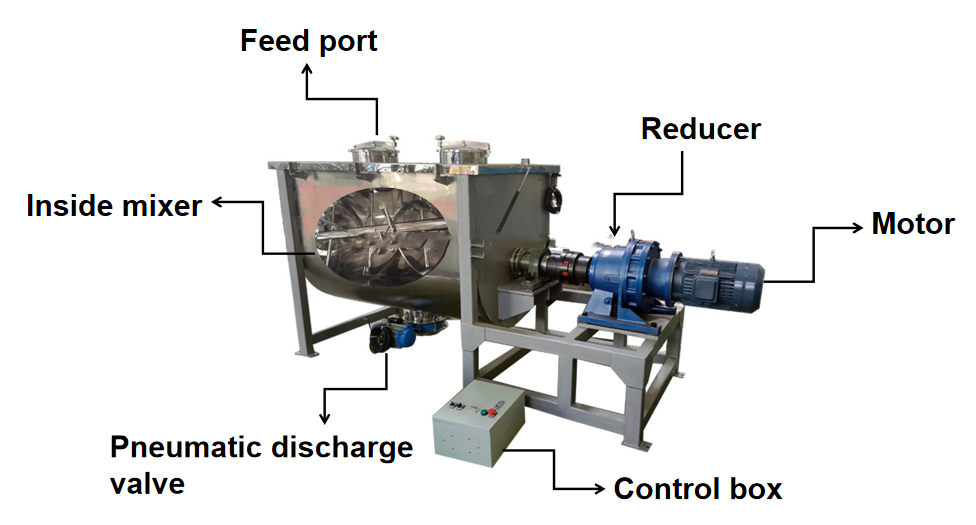

It adopts U-shaped barrel, inner and outer double-layer spiral ribbon stirring shaft, motor, feeding and discharging device and other bar systems.

Bidirectional spiral ribbon rotor: It consists of main spiral ribbon and auxiliary spiral ribbon, made of 304/316L stainless steel or special alloy

Mixing blade: multi-layer design (usually 3-5 layers), blade thickness 8-15mm, surface polishing.

Drive device: equipped with cycloidal pinwheel/gear reduction motor (power 5.5-55kW), variable frequency speed control

Mixing tank: U-shaped or W-shaped design, volume 100-10000L, with jacket (optional steam/circulating water temperature control)

Sealing system: double-end mechanical seal (sealing pressure ≤ 0.6MPa) + packing seal composite structure

Frame: heavy carbon steel welded frame (surface anti-corrosion treatment), with shock absorber.

The industrial powder ribbon mixer achieves mixing through the rotation of double-layer reverse ribbons in the U-shaped cylinder. The outer ribbon rotates right to push the material from both ends to the center, and the inner ribbon rotates left to transport the central material to both ends, forming a "radial convection + axial circulation" movement. The material is quickly and evenly mixed in repeated shearing, diffusion and flipping.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

This equipment is widely used in fine chemicals, medicine, new energy, food additives and other industries, providing 99% high uniformity mixing, supporting explosion-proof, temperature control and other customization.

Catalyst preparation: The active components are mixed with the molecular sieve carrier, and the catalyst particles are prevented from breaking by gentle stirring of the spiral ribbon. A petrochemical enterprise uses a 316L stainless steel mixer to achieve uniform distribution of active components of hydrogenation catalysts, and the catalytic efficiency is increased by 15%.

Polymer material modification: During the mixing process of PVC resin with plasticizer and stabilizer, the shearing action of the spiral ribbon promotes the penetration of additives, and the plasticization time of the mixed material is shortened by 20%.

Pesticide powder production: Through the dust-proof sealing design (negative pressure ventilation at the shaft seal), the dust overflow problem when sulfur powder and organophosphorus pesticides are mixed is solved, which meets the environmental protection requirements of the chemical industry.

When choosing a suitable mixer, you need to pay attention to material properties, mixing requirements and other working conditions.

Material properties: Corrosive materials use 316L stainless steel + Teflon coating; flammable and explosive materials are equipped with explosion-proof motors and anti-static grounding systems.

Mixing volume requirements: The standard model has a volume of 0.1-10m³, and it is recommended that the loading volume be controlled at 40%-60% of the cylinder volume to ensure mixing efficiency.

Process integration: When heating and mixing are required, the jacket heat transfer coefficient should be ≥800W/(㎡・K); liquid addition and mixing require a spiral ribbon structure with a guide plate to prevent local agglomeration of the liquid.

Dahan Machinery has focused on the research and development and manufacturing of industrial powder spiral ribbon mixers for many years, with strong technical strength. The product models are rich, covering carbon steel material series and stainless steel material series. The carbon steel model is cost-effective and uses Q235B or Q345R carbon steel. It is treated with anti-corrosion such as plastic spraying and galvanizing. It is wear-resistant and strong in load-bearing, and is suitable for non-corrosive chemical raw materials. The stainless steel model uses 304/316L material, which is corrosion-resistant and easy to clean. It meets strict hygiene standards and meets the needs of food, medicine, and fine chemicals. The manufacturer provides customized services and perfect after-sales service to fully guarantee the customer's experience.

Specified equipment helps customers achieve efficient and accurate raw material mixing process. Support non-standard customization, welcome to inquire for industry solutions!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.