Organic Fertilizer Compost Rotary Mixer is the core equipment of modern agriculture and organic waste treatment. It adopts mechanical turning technology to quickly mix raw materials such as poultry and livestock manure, straw, kitchen waste, etc., greatly shortening the composting cycle and improving the maturity and fertilizer efficiency. Compared with manual turning, its automated operation saves more than 60% of labor costs, uniform mixing ensures sufficient aerobic fermentation, and stable temperature (60-70℃) can effectively kill pathogens and weed seeds.

Depending on different processing scales and process requirements, there are many types of organic fertilizer compost rotary mixers, but their core principle is to mix and turn the compost materials through rotating stirring parts.

Horizontal rotary mixer: The materials are mixed in the horizontal cylinder through the rotating stirring shaft and paddles. This type of mixer has a compact structure and good mixing effect, and is suitable for processing materials with high water content.

Vertical rotary mixer: The mixing shaft is arranged vertically, and the material is lifted and turned from the bottom through the spiral or plow-shaped mixing parts. The vertical mixer occupies a small area and is easy to unload.

Drum mixer: The material is mixed and turned in the rotating drum by friction and internal stirring ribs. This mixer has a simple structure and is easy to maintain, suitable for compost with a large amount of processing.

The rotary mixer drives the drum or paddle to rotate through a motor or hydraulic pressure to turn, crush and mix the compost material.

Even mixing: Make the raw materials, bacterial agents and auxiliary materials fully contact to improve the fermentation efficiency.

Oxygenation ventilation: Promote aerobic microbial activity and reduce the odor produced by anaerobic fermentation.

Adjust moisture: Evaporate excess moisture during the turning process to optimize the compost humidity (50%~60% is best).

Breaking lumps: Break up the material to improve the looseness and uniformity of the compost.

With its high speed and intelligent features, the organic fertilizer compost rotary mixer has become a key equipment for modern compost production, helping to utilize agricultural waste resources and promote sustainable agricultural development.

Improve fermentation efficiency: shorten the composting cycle (traditional composting takes 2 to 3 months, while mechanical turning can be shortened to 15 to 30 days).

Save manpower: mechanized operation replaces manual turning, saving more than 70% of labor costs; aerobic fermentation reduces the emission of harmful gases such as methane and hydrogen sulfide, which meets the requirements of green agriculture.

Strong adaptability: It can handle a variety of organic wastes such as livestock and poultry manure, straw, kitchen waste, sludge, etc., and can break up agglomerated materials to improve the looseness of compost.

Convenient operation: Some models are equipped with automatic temperature and humidity monitoring, remote control and other functions to accurately optimize fermentation conditions and reduce manual intervention.

Durability: Made of 304 stainless steel or anti-corrosion coating material, it is corrosion-resistant, wear-resistant, and stable in long-term operation; modular design facilitates cleaning and component replacement.

When the organic fertilizer compost material enters the mixing tank, the mixer starts, and the mixing shaft drives the blades to rotate at high speed. Taking the propeller blade as an example, during the rotation process, the blade pushes the material from one end of the mixing tank to the other end, and at the same time, the material produces strong convection movement in the axial and radial directions, realizing all-round mixing of the material.

Organic fertilizer compost rotary mixer is widely used in agriculture, breeding and circular economy due to its efficient mixing, oxygenation and fermentation functions, and is suitable for the treatment and resource utilization of various organic wastes.

Livestock and poultry breeding: Organic fertilizer compost rotary mixer is mainly used for harmless treatment of livestock and poultry manure in farms, which can effectively reduce odor and pathogens and produce high-quality organic fertilizer

Agricultural field: It is suitable for composting agricultural by-products such as straw, fruit and vegetable waste, and realizing resource recycling.

Scaled production of organic fertilizer: This equipment is the core machinery of commercial organic fertilizer processing plants. It can efficiently process various organic raw materials and produce high-quality biological organic fertilizer with microbial agents.

Garbage disposal: Mixers can be used to treat urban organic waste such as kitchen waste and sludge, and achieve garbage reduction and resource utilization through aerobic fermentation.

Soil improvement: Fermented organic fertilizer can be used to improve saline-alkali land and degraded soil to improve soil fertility; in the field of landscaping, it is used for composting waste such as dead branches and leaves to make green cultivation substrates.

|

Comparison Item |

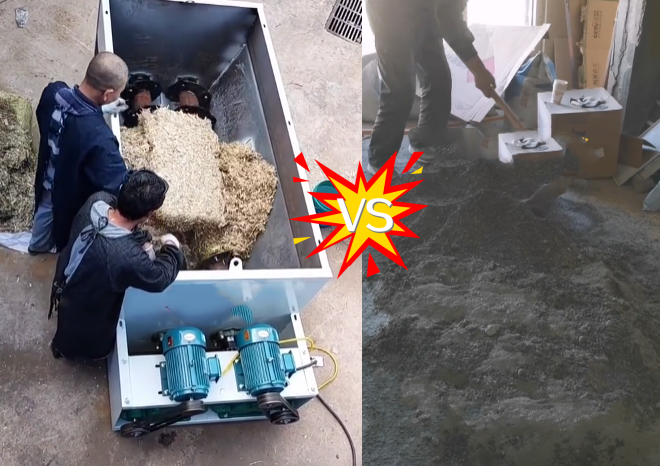

Manual Turning |

Organic Fertilizer Composting Rotary Mixer |

Advantage Comparison |

|

Work Efficiency |

2-3 tons per person/day |

5-20 tons per hour |

fficiency improved by 5-8 times |

|

Fermentation Cycle |

2-3 months |

15-30 days |

Cycle shortened by 50%-75% |

|

Labor Cost |

Requires continuous heavy labor input |

1 person can operate |

Labor cost saved by over 60% |

|

Fermentation Quality |

Uneven, prone to anaerobic zones |

Uniform mixing, thorough aerobic fermentation |

Fertilizer efficiency increased by 30% |

|

Temperature Control |

Difficult to maintain stable high temperature |

Can maintain 60-70℃ continuous high temperature |

More thorough sterilization |

|

Environmental Performance |

Open operation, odor diffusion |

Closed/semi-closed design, reduced emissions |

More environmentally friendly |

|

Material Adaptability |

Only suitable for low-humidity loose materials |

Can handle high-humidity (70%) and viscous materials |

Broader application range |

Dahan Machinery focuses on the research and development of high-speed and durable compost rotary mixers. Our equipment is made of 304 stainless steel, equipped with 15-30kW motors, and has a processing capacity of 5-20 tons/hour, which can meet the production needs of organic fertilizers of different scales. Core products include trough-type compost turners (fermentation cycle shortened to 15 days), crawler compost turners (adapted to open-air operations) and other series, all of which have passed CE certification and have the characteristics of low energy consumption and high mixing uniformity (up to 95%). In addition, suitable mixing equipment can be made for you according to your needs.

Organic fertilizer compost rotary mixer is an indispensable and important equipment in modern organic fertilizer production. It optimizes the composting environment and accelerates the decomposition of organic matter through mixing operations, significantly improving the quality and production efficiency of organic fertilizer. Choosing a suitable rotary mixer will greatly improve the organic fertilizer production process and inject new vitality into the sustainable development of agriculture and horticulture.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.