Pesticide Horizontal Mixer is one of the indispensable key equipment in the pesticide production process, especially in the production of solid pesticide preparations such as powder, wettable powder, granule, etc. It undertakes the important task of uniformly mixing various materials such as pesticide original medicine, carrier, adjuvant, etc. Its mixing effect directly affects the quality of the final pesticide product, the uniformity of efficacy and the safety of use.

The pesticide horizontal mixer (horizontal ribbon mixer) is specially designed for the production of pesticide preparations and has the following outstanding features.

It adopts a fully enclosed 316L stainless steel structure with strong corrosion resistance.

The CV value of mixing uniformity is ≤3%, ensuring the precise distribution of active ingredients.

Explosion-proof motor + static elimination device, safety level Ex dⅡBT4.

The residual amount is less than 0.5%, which meets the FAO/WHO pesticide production specifications.

The working principle of the pesticide horizontal mixer is based on the dual effects of mechanical stirring and material movement. When the equipment is started, the motor drives the stirring shaft to rotate through the transmission device, and the stirring blades installed on the stirring shaft rotate at high speed. The movement of the stirring blades causes the material to produce a complex flow state. The centrifugal force and thrust generated by the rotation of the paddle blades and anchor blades cause the material to diffuse to the side wall of the stirring tank, and then return to the center, forming a radial circulation flow, which promotes the mixing and dispersion of the materials.

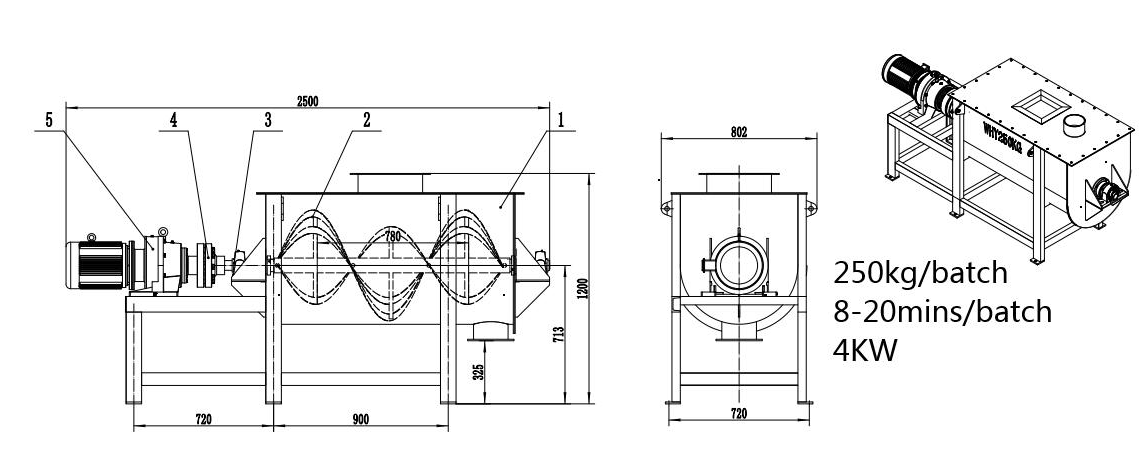

The pesticide horizontal mixer is mainly composed of a stirring tank, a stirring shaft, stirring blades, a transmission device, a feed port and a discharge port.

Mixing tank: A horizontally placed tank structure, usually made of stainless steel or corrosion-resistant materials to adapt to the corrosiveness and chemical properties of pesticide materials.

Mixing shaft and stirring blades: The stirring shaft runs through the center of the stirring tank and is driven to rotate through the transmission device. The material of the stirring shaft has high strength and wear resistance to withstand the torque and friction generated during the mixing process. The stirring blades are installed on the stirring shaft and are the key components for achieving material mixing.

Transmission device: The transmission device is composed of a motor, a reducer, a coupling and other components.

Feed inlet and discharge inlet: The feed inlet is set above the mixing tank to facilitate the addition of materials. The feeding method can be manual feeding, spiral conveying, pneumatic conveying and other forms, which can be selected according to the production process and material characteristics.

|

Model |

LHY-0.25 |

LHY-0.5 |

LHY-1 |

LHY-1.5 |

LHY-2 |

LHY-3 |

LHY-4 |

LHY-6 |

LHY-8 |

LHY-10 |

|

One-time mixing (kg) |

100-150 |

200-300 |

400-600 |

600-900 |

800-1000 |

1200-1800 |

1600-2400 |

2400-3600 |

3200-4800 |

4000-6000 |

|

Mixing time (min) |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

8-20 |

|

Mixing speed (r/min) |

60 |

55 |

45 |

40 |

35 |

25 |

25 |

20 |

15 |

15 |

|

Motor power (kw) |

3-5.5 |

4-11 |

7.5-15 |

11-18.5 |

15-22 |

18.5-30 |

22-37 |

37-55 |

37-55 |

45-75 |

|

Weight (kg) |

500 |

900 |

1800 |

2500 |

3200 |

4100 |

5100 |

6300 |

7500 |

|

Pesticide horizontal mixers are generally suitable for mixing various types of pesticide products, including pesticide raw materials in the form of powder, granules, liquids, and liquid powders.

Powdered pesticides: including fine powder and granular pesticide products, such as powdered pesticide raw materials such as insecticides and fungicides.

Granular pesticides: Some pesticide products exist in the form of granules and need to be mixed to ensure the uniform distribution of various ingredients.

Liquid pesticides: Some pesticide products exist in the form of liquids and need to be fully mixed with other raw materials to obtain the final pesticide formulation. Horizontal mixers can mix liquid pesticides with other auxiliary raw materials evenly.

Liquid powder pesticides: Some pesticide products are in the form of liquid powders, that is, granular powders are suspended in the liquid, and mixing is required to ensure the uniform distribution of particles. Pesticide horizontal mixers are also suitable for mixing this type of pesticide products.

Pesticide horizontal mixers can efficiently handle a variety of dosage forms such as powders, granules, liquid-solid mixtures, etc. When selecting, it is necessary to match the equipment material and function according to the characteristics of the pesticide (corrosiveness, viscosity, toxicity) to ensure mixing uniformity and production safety!

|

Pesticide Type |

Recommended Mixer Model |

Key Configuration |

|

Powder |

Horizontal Screw Ribbon Mixer |

Dust-proof Sealing + Frequency Conversion Speed Regulation |

|

Granules |

Twin Shaft Paddle Mixer |

Low Rotation Speed (20-40rpm) |

|

Liquid + Powder |

Spray Mixer |

316L Stainless Steel + High-pressure Atomizing Nozzle |

|

Highly Corrosive |

Lined Plastic/Enamel Mixer |

Acid and Alkali-resistant Material + Exhaust Gas Recovery |

Pesticide horizontal mixers play a key role in pesticide production. Through effective mixing and stirring, the quality of pesticide products can be ensured to be stable and the composition is uniform, thereby improving the use effect and production efficiency of pesticides. Choosing a suitable pesticide horizontal mixer is crucial to improving the efficiency and quality of the pesticide production process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.