Stainless Steel Mixer For Baking Ingredients is made of 304/316L food-grade stainless steel, CE certified, and specially designed for baking production such as bread, cakes, and biscuits. The equipment is equipped with variable frequency speed regulation and multiple types of stirring paddles (S-shaped/hook-shaped/paddle-shaped), which can complete high-uniform mixing in 3-10 minutes, with a single batch processing capacity of 50-1000kg, suitable for dough, powder and high-fat raw materials, and a residual rate of <0.3%.

We provide food-grade stainless steel mixers with a variety of capacities from 10L to 1000L, suitable for various raw materials such as flour, cake batter, biscuit powder, etc., and support customization.

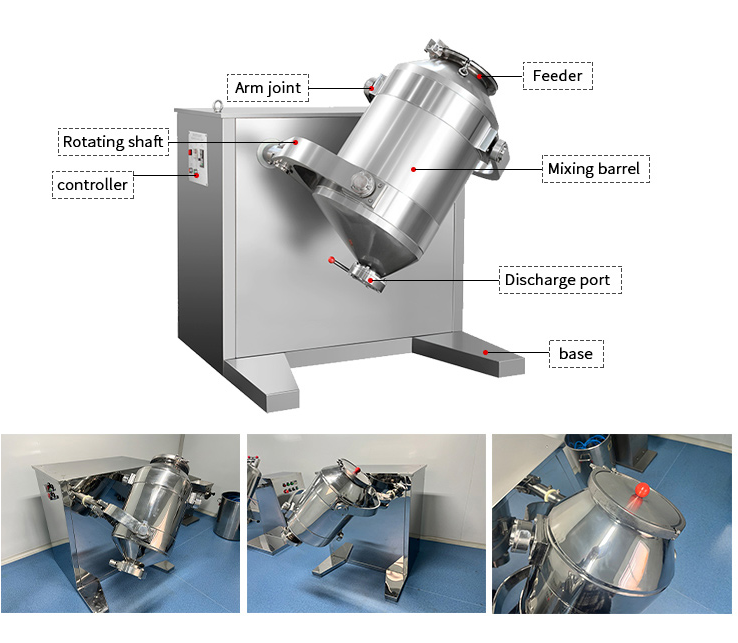

Three-dimensional mixer: With its unique design, it can achieve 360-degree mixing without dead angles when mixing materials. The special movement of the barrel can enable the material to perform complex translation, flipping, diffusion and other movements in space, with excellent mixing effect and high uniformity.

Horizontal mixer: When working, the inner and outer spiral belts on the stirring shaft cooperate with each other to turn the material back and forth in the barrel. The inner spiral belt pushes the material from the middle to the sides, and the outer spiral belt pushes the material from the sides back to the center, forming a convection cycle, so that the material can be quickly and evenly mixed in a short time.

V-type mixer: It is a high-efficiency asymmetric mixing equipment with a simple structure and closed operation. The V-shaped barrel is driven by a motor to continuously operate, driving the material in the barrel to move up and down, left and right, and front and back in multiple directions to achieve full mixing.

Rapid mixing in 3-10 minutes, uniformity CV≤5%, residual rate <0.3%, and its advantages also include the following points.

304/316L stainless steel liner: corrosion-resistant and rust-proof, in line with FDA, CE, EHEDG food hygiene standards, ensuring no risk of heavy metal migration.

Multiple types of paddles are available: S-shaped paddles are suitable for high-gluten dough, hook-shaped paddles are suitable for handling high-viscosity materials, and paddles are suitable for quickly mixing cake batters and biscuit powders in 3-5 minutes.

PLC touch screen control: 50+ recipes are preset, and time, speed and other parameters are automatically recorded to ensure batch consistency.

Weighing batching system (optional): Accurate feeding, error ≤0.5%, reducing manual intervention.

Temperature control options: The sandwich design supports heating (to 80°C) or cooling (to -10°C) to handle sensitive raw materials such as chocolate and cream.

Anti-stick treatment: Teflon-coated paddles (optional) solve the problem of sticking to the cylinder for high-sugar and high-fat formulas.

CIP online cleaning (optional): Pipeline spray system, deep cleaning in 30 minutes.

The main body consists of a precision-polished mixing barrel, a mixing paddle, a variable frequency drive system, etc. The modular design is easy to maintain and meets the baking industry's stringent requirements for hygiene, efficiency and intelligent production.

Mixing barrel: 304 stainless steel liner, mirror polished (Ra≤0.8μm), easy to clean and corrosion-resistant.

Mixing paddle: optional S-shaped, hook-shaped or paddle-shaped design, suitable for raw materials of different viscosities (such as dough, powder).

Drive system: variable frequency motor (3-15kW), adjustable speed 20-200rpm, to meet the needs of low-speed kneading to high-speed mixing.

Temperature control options: sandwich design, support heating/cooling (-10℃ to 80℃), handle chocolate or cream that needs temperature control.

Intelligent control: PLC touch screen, preset 10-50 groups of recipes, automatic recording of process parameters.

When working, it performs complex spatial movements around multiple axes, including translation, flipping and rotation. The material is affected by gravity, centrifugal force and shear force generated by the movement of the cylinder, and is constantly lifted, thrown and flipped in the cylinder, forming multi-directional convection and diffusion in three-dimensional space. Because the movement of materials in different directions is intertwined, various materials can be mixed quickly and evenly.

Perfectly adapted to the production needs of all categories such as cakes, bread, biscuits, etc., meeting the stringent requirements of modern baking technology for hygiene, efficiency and quality.

Dry raw materials: flour, powdered sugar, milk powder, etc., mixing uniformity CV≤5%.

Wet raw materials: eggs, milk, oil, support liquid quantitative spraying system.

High viscosity dough: bread, pizza dough, kneading dough evenly without sticking to the cylinder.

Functional addition: trace ingredients such as yeast and leavening agents are accurately dispersed.

With its food-grade safety standards and efficient mixing performance, stainless steel mixers for baking ingredients fully cover the application scenarios of all links in the baking industry chain.

Stainless steel mixers for baking ingredients play a key role in many scenarios with their excellent performance and reliable quality.

Baking food production factory: In large-scale bread/pastry mass production, baking raw material stainless steel mixers can efficiently mix doughs such as toast and European bread to ensure uniform fermentation and improve the fluffiness of the finished product.

Central kitchens and chain bakery stores: Relying on the standardized production capacity of stainless steel mixers, the dough formula of each store can be unified to ensure consistent product taste. At the same time, it supports batch production of frozen dough and produces semi-finished products that can be refrigerated/frozen, which greatly saves store operation time. .

Health and functional food processing: In gluten-free baking, mixers can effectively mix alternative raw materials such as brown rice flour and almond flour to solve the problem of easy stratification; in the face of low-sugar/sugar substitute formulas, erythritol, stevia, etc. can be evenly dispersed.

Catering and hotel kitchens: Stainless steel mixers help dessert making, can batch process mousse and pudding bases, and significantly improve production efficiency.

Food R&D and laboratories: Small-capacity (10-50L) mixers have become a powerful tool for new product development, facilitating the testing of formula ratios and optimizing process parameters; in raw material testing, the mixing compatibility of different flours and additives can be evaluated.

|

Indicator |

Stainless Steel Mixer |

Manual/Ordinary Mixing |

|

Mixing Time |

-10 minutes/batch |

15-30 minutes/batch |

|

Uniformity |

CV≤5% |

High manual error (CV≥15%) |

|

Productivity |

100-500kg/hour |

Low efficiency relying on manpower |

|

Hygiene Standard |

Food-grade certification |

High risk of contamination |

As a professional stainless steel mixer manufacturer for baking ingredients, Dahan Machinery has many years of industry experience and provides a full range of food-grade 304 stainless steel equipment from 50L to 1000L. The products are CE certified and have intelligent functions such as variable frequency speed regulation, PLC control, temperature control and CIP cleaning. The mixing uniformity CV≤5% has served listed baking companies, international chain brands and other customers, providing customized solutions and fast delivery. It is your exclusive mixing solution manufacturer.

The stainless steel mixer for baking ingredients is an indispensable core equipment in modern baking production lines. Its excellent hygienic performance, high-speed mixing ability and professional design for baking processes not only greatly improve production efficiency and ensure food safety, but more importantly, it provides bakers with tools to accurately control the mixing of raw materials, thereby stably producing high-quality and delicious baking products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.