Twin Shaft Paddle Mixer For Bulk Materials is designed for powdery, granular and sticky materials. It is made of 304 stainless steel/carbon steel and equipped with a 7.5-55kW dual motor drive system. The mixing uniformity CV≤5%, the single batch processing volume is 0.5-6m³, and the mixing is completed quickly in 3-5 minutes. The equipment achieves triple mixing of convection, shear and diffusion through a unique counter-rotating dual-shaft + multi-angle paddle design, with a residual rate of <0.3% and energy consumption as low as 0.6kWh/t!

Adopting a bidirectional stirring shaft + multi-angle paddle design, the mixing uniformity CV≤5%, 3-5 minutes/batch is completed at high speed.

Fast mixing: 3-5 minutes/batch, uniformity CV≤5%, far exceeding traditional single-shaft mixers.

Widely applicable: can handle powdery (such as flour, additives), granular (such as feed, fertilizer) and sticky materials (such as sludge, rubber powder).

Low energy consumption: energy consumption per ton of material ≤ 0.6kWh, energy saving more than 20%.

Low residue: the discharge door design makes the residue rate <0.3% to avoid cross contamination.

Intelligent control (optional): PLC system supports formula storage and data traceability, in line with GMP standards.

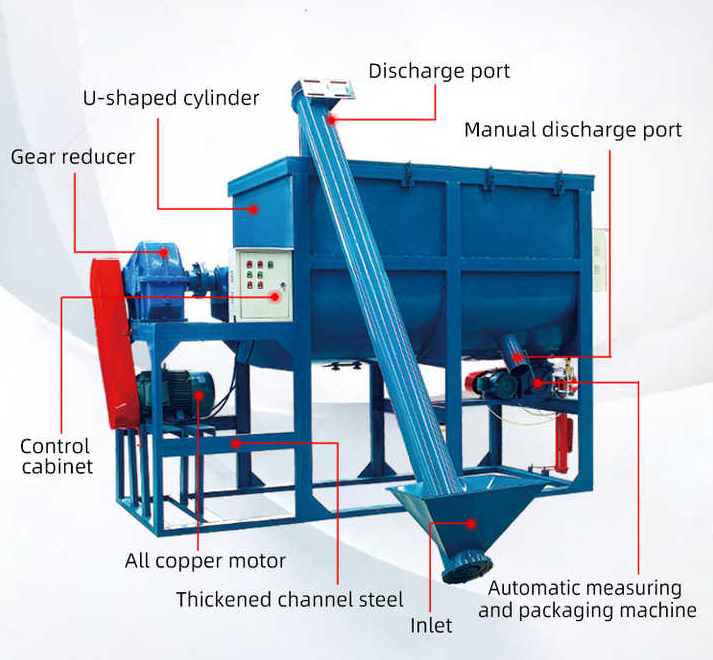

The main body of the equipment adopts 6-12mm thick carbon steel/304 stainless steel box, equipped with double parallel stirring shafts and other structures, meeting the strict standards of food, chemical, feed and other industries.

Box: 6-12mm thick Q345 carbon steel or 304 stainless steel welding

Sealing system: Silicone + polyurethane composite seal (temperature resistance -20℃~120℃)

Observation window: 2-4 visual cleaning windows are standard (pressure resistance 0.6MPa)

Mixing shaft: dual-axis parallel arrangement, shaft diameter Φ200-500mm (depending on capacity)

Paddle configuration: 8-16 sets of special angle paddles per shaft (25°/45°/60° optional)

Motor: Dual 7.5-75kW variable frequency motors (protection level IP55)

|

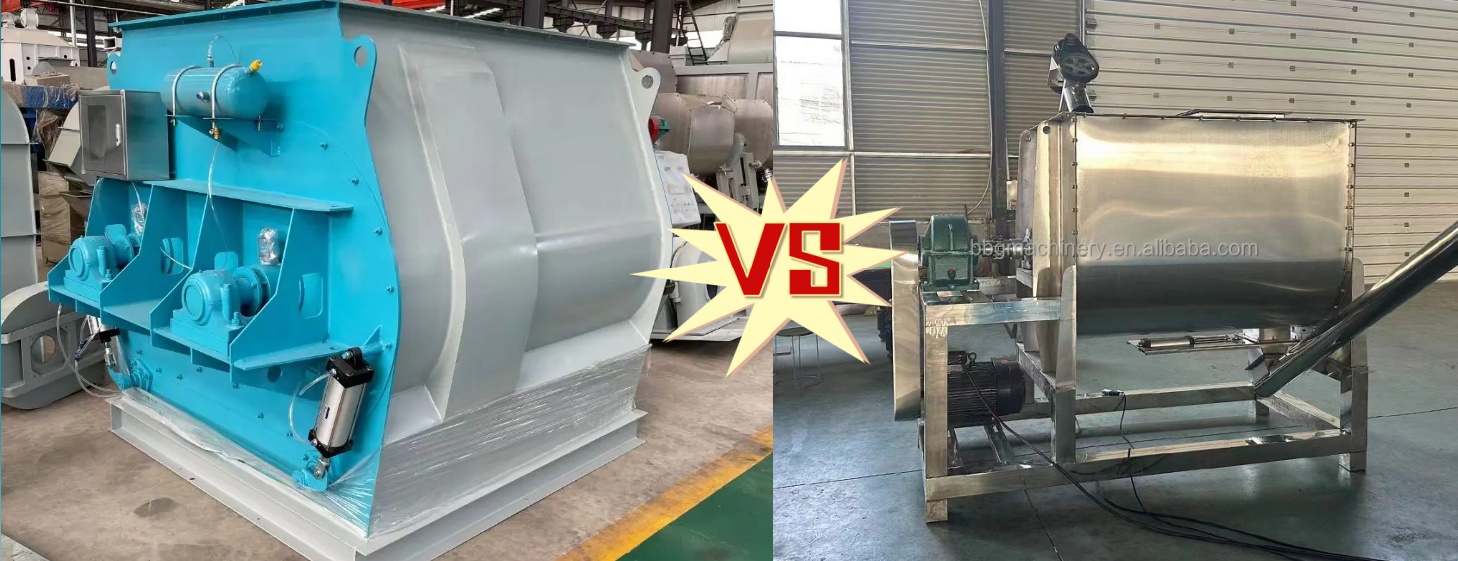

Comparison Dimension |

Double-Shaft Paddle Mixer |

Single-Shaft Mixer |

|

Mixing Motion Trajectory |

Axial (0.3-0.8m/s) + radial (spray height 300-600mm) + tangential (speed ratio 1:1.2~1.5), 3D composite motion |

Single-plane rotation, weak axial/radial motion, low tangential speed ratio |

|

Mixing Time |

3-5 minutes/batch |

8-15 minutes/batch |

|

Uniformity (CV Value) |

CV≤5% |

CV≤8% |

|

addle Layout |

Staggered multi-paddles, weightless zone formed by dual-shaft intersection |

Single paddle or spiral paddle layout |

|

Power Configuration |

Independent dual-motor drive with differential speed control |

Single-motor central drive |

|

Applicable Material Types |

High-viscosity materials (≤15,000cP), materials with 5-8% liquid addition, density difference ≥1:3 |

Low-viscosity dry powders, liquid addition ≤3%, materials with similar densities |

|

Special Functions |

Can be equipped with liquid spraying/jacket devices, supporting solid-liquid mixing and drying |

Single function, only suitable for pure dry material mixing |

|

Raw material loss reduced by 5-8%, suitable for large-scale production |

Raw material loss reduced by 5-8%, suitable for large-scale production |

Suitable for small-batch production; long-term benefits depend on production capacity needs |

|

Typical Application Scenarios |

Premixes, dry-mixed mortars, feeds (with liquid addition), chemical pigment mixing |

Simple dry powder mixing, laboratory small-batch production, low-viscosity materials (e.g., flour, cement) |

The bulk material twin-shaft paddle mixer achieves high-speed mixing through axial, radial and tangential motion coordination. During axial movement, the blades push the material along the axis at a speed of 0.3 - 0.8m/s; during radial movement, the material is centrifugally diffused under the action of the blades, and the throwing height reaches 300 - 600mm; the tangential movement relies on reverse rotation to produce a differential speed ratio of 1:1.2 - 1.5. Its mixing mechanism covers the forced convection zone, where the blades act directly and the mixing intensity is the highest; in the diffusion exchange zone, the material falls freely to complete micro-mixing.

It can quickly process high-viscosity materials (≤15,000cP), composite materials containing 5 - 8% liquid addition, and materials with a large density difference of ≥1:3, suitable for premixes, dry mortar, liquid feed, chemical pigments and other scenarios.

Powder materials: Suitable for mixing all kinds of fine powders, ultrafine powders and lightweight powders, including ultrafine powders such as cement, fly ash, nano calcium carbonate, silica, and lightweight materials such as expanded perlite and wood fiber, ensuring high uniformity (CV≤5%) and no stratification.

Granular materials: Mixed regular granular plastic particles, feed particles, irregular granular slag, biomass particles, aspect ratio ≤3:1 and compound fertilizers, catalysts, density difference ≤1:3, to meet the mixing needs of different particle sizes and densities.

Special materials: Designed for sticky, heat-sensitive and dangerous goods, it can handle sticky materials such as sludge and rubber powder with a moisture content of ≤40%, heat-sensitive materials such as PVC paste resin and food additives with a temperature resistance of ≤80℃, and flammable and explosive materials that require explosion-proof configuration.

Twin-shaft mixer feed to sludge conditioning is widely used in many industries. The following are some of our customers' feedback

Large feed companies: Customers want to improve the mixing uniformity of vitamins and trace elements and reduce batch differences. Use SJS-10 twin-shaft paddle mixer (1m³ capacity, stainless steel material) with integrated PLC automatic batching system. Mixing uniformity CV≤3%, single batch processing time is shortened to 4 minutes, and production capacity is increased by 40%.

Chemical companies: Solve the problem of uneven mixing caused by the density difference (1:2.5) between catalyst carrier and active ingredient. Customized explosion-proof twin-shaft mixer (2m³ volume, with nitrogen protection). Achieve high-precision mixing of materials with different densities (CV≤4%) with a mixing cycle of 5 minutes/batch.

Sludge conditioning mixing: Treat municipal sludge with a moisture content of 35%. Traditional mixers are prone to wall adhesion and agglomeration. Choose a heavy-duty twin-shaft mixer (paddle with self-cleaning function) + heating system (60℃),

The wall adhesion rate is reduced by 90%, the cleaning time is reduced by 70%, and the daily processing capacity is increased from 80 tons to 150 tons.

The company is equipped with a professional R&D team, deeply researching mixing technology, and creating high-speed and stable mixer products for the needs of different industries. The twin-shaft paddle mixer produced has high mixing efficiency, and a batch of mixing can be completed in 3-5 minutes, and the uniformity reaches CV≤5%. The internal staggered multi-blade layout is adopted, and the double shafts cross to form a weightlessness zone. With independent dual motor drive, it can handle high-viscosity materials (≤15,000cP), adapt to materials containing 5-8% liquid addition and density difference ≥1:3, and can also be equipped with spray/jacket devices as needed to provide customers with a full range of mixing solutions.

The twin-shaft paddle mixer has become a leader in the field of bulk material mixing with its unique structural design, high-speed working principle, excellent performance advantages and wide application fields. It provides reliable technical support for the production processes of various industries, helping enterprises to improve product quality, increase production efficiency and reduce production costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.