Twin Shaft Paddle Mixer For Feed Mills adopts a two-way mixing design, with high mixing uniformity (CV≤5%), strong processing capacity (1-6m³/batch), and can complete efficient mixing in 3-5 minutes, with energy consumption as low as 0.6kWh/t. The equipment is made of high-quality carbon steel or stainless steel, suitable for powder, granular materials and high-fat formula (below 8%), with a residual rate of less than 0.3%, ensuring balanced feed nutrition. It supports customized configuration, including intelligent control system, liquid addition device, etc., to meet the needs of feed mills of different sizes.

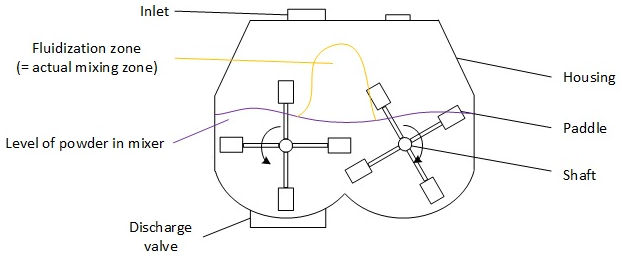

The twin-shaft paddle mixer adopts two counter-rotating paddle shafts with a unique paddle design, which can produce strong convection, shear and diffusion effects during the mixing process.

Fast mixing speed: Usually a batch of mixing can be completed within 45-120 seconds, greatly improving production efficiency.

High mixing uniformity: The coefficient of variation (CV) can reach less than 5% or even lower, ensuring the nutritional balance of each batch of feed.

Low residue: The optimized discharge door and internal structure minimize material residue and avoid cross contamination.

The twin-shaft paddle mixer is based on a U-shaped wear-resistant cylinder, with dual-shaft reverse drive and staggered paddles, fully enclosed seal, intelligent transmission and modular easy-to-maintain design, laying a solid foundation for quality and production capacity for feed mills.

Mixing box: welded with 6-12mm thick carbon steel or stainless steel (304/316L), the interior is smooth without dead corners, easy to clean and corrosion-resistant.

Twin stirring shafts: two parallel main shafts, made of alloy steel, surface hardened, and strong wear resistance.

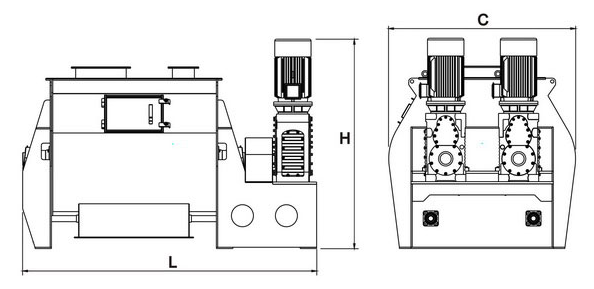

Dual motor + reducer: independently drive dual shafts, power 7.5-75kW (selected according to capacity), support variable frequency speed regulation.

Transmission mode: synchronous transmission by gear or sprocket to ensure the counter-rotation of the two shafts.

Auxiliary system (optional): liquid addition spray device, online moisture detector, PLC automatic control system

The twin-shaft paddle mixer achieves efficient mixing of materials in three-dimensional space through the synergistic effect of two counter-rotating stirring shafts and multi-angle paddles: first, large-scale convection mixing is completed through the axial push of the paddles, and then the cross-shear force generated by the reverse rotation is used to break the agglomerates, and finally the microscopic diffusion mixing is achieved by material throwing. The typical workflow includes three stages: feeding (filling rate 60%-80%), mixing (twin-shaft 20-50rpm speed, 3-5 minutes to complete) and unloading (fast discharge at the bottom, residual rate <0.3%), ensuring that the feed reaches a uniformity of CV≤5% in a short time, while avoiding cross-contamination between batches..

Due to its high-speed mixing performance, the twin-shaft paddle mixer is widely used in livestock, poultry, aquatic products, ruminant feed and premix production.

Livestock and poultry feed: mixed pig complete feed (corn 60% + soybean meal 20% + premix 20%), ensure balanced nutrition such as amino acids, calcium and phosphorus, and increase the daily weight gain of fattening pigs by 5%-8%;

Aquatic feed: mixed shrimp puffed feed (fish meal 30% + flour 40% + phospholipid oil 5%), anti-stratification design to avoid oil sedimentation, and reduce the feed conversion ratio (FCR) by 10%;

Ruminant feed: mixed dairy cow concentrate supplement (corn 50% + cottonseed meal 25% + baking soda 3%), ensure uniform distribution of rumen buffer and reduce the risk of acidosis;

Premix production: mixed vitamin premix (vitamin A 0.01% + carrier 99.99%), with a uniformity of 98%, meeting the high-precision requirements of feed additive companies.

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight(kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

We are well aware that the production process and needs of each feed mill are unique. Therefore, in the design and manufacture of twin-shaft paddle mixers, we always put customer needs first and provide highly customized solutions.

Capacity customization: According to your actual production volume requirements, we provide mixers of different volumes from small to large to ensure that the equipment matches your production line perfectly.

Material selection: According to the corrosiveness or hygiene requirements of the material, you can choose different materials such as carbon steel, stainless steel (such as 304, 316L) to ensure the service life of the equipment and product quality.

Additive liquid interface and atomization system: In response to the needs of liquid addition, a high-precision liquid addition system and atomization nozzle can be integrated to ensure uniform spraying of the liquid and avoid agglomeration.

Intelligent control system: It can be equipped with an advanced PLC control system to achieve automated operation, formula management and production data tracking, and improve the level of intelligent production.

The price of the twin-shaft paddle mixer mainly depends on factors such as equipment specifications, material configuration and production capacity. Equipped with a variable frequency motor and an intelligent control system, although the investment is higher, the long-term operating cost is lower. Equipment prices are also affected by brand premium, customization requirements, and after-sales service content. Investing in an excellent twin-shaft paddle mixer is investing in the future of your feed business. Contact us now and let us work together to improve your feed production level!

Choosing a twin-shaft paddle mixer suitable for your feed mill is a key step to improve production efficiency and feed quality. We know that efficient and stable mixing is the basis of high-quality feed. We not only provide high-performance mixing equipment, but also strive to become a reliable partner on your production line and tailor-make the mixing solution that best meets your needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.