V-type powder mixer also known as V-shaped powder mixer or V-type blender, is an industrial mixing equipment suitable for mixing powders and granules with good fluidity and small differences in physical properties. Since the materials in the V-shaped mixing container can flow smoothly without damaging the original shape of the materials, they are also suitable for mixing granular materials that are easy to break and wear, or for mixing finer powders, block materials, and materials containing a certain amount of moisture.

The V-type powder mixer, with its unique structural design and flexible customization capabilities, is an ideal choice for laboratory trials and small- to medium-sized production runs. All material-contacting parts are constructed of 304 or 316 stainless steel. The equipment supports full customization, especially the overall height, which can be adjusted to suit the customer's workshop space and loading and unloading station layout. Customizable inlet size, discharge valve type, and mixing speed allow the equipment to seamlessly integrate into existing production lines, meeting diverse mixing needs from dry powders to lightly wetted powders. It provides customized mixing solutions for users in various industries.

The 50L, 100L, 100L, 200L, and 300L V-type mixers we launched are tailored for different material characteristics and production scales. The following is a detailed analysis of the adaptation scenarios and material types of each capacity model.

50L V-type mixer: suitable for laboratory research and development, small-scale trial production, and small-batch production of high-end customized products.

100L V-type mixer: suitable for daily production of small and medium-sized enterprises, medium-scale product research and development and production, and some production links with high mixing accuracy requirements. For example, the production of specialty products in regional food processing plants and the manufacture of special chemicals for small chemical companies.

200L V-type mixer: suitable for conventional production of large and medium-sized enterprises, large-scale product formula mixing, and continuous production links that require high production efficiency. Such as the mixing of staple food ingredients in large food processing plants and standardized batch production of chemical raw materials.

300L V-type mixer: large-scale industrial production, high-yield standardized product manufacturing, and scenes with extremely high requirements for mixing efficiency and production continuity. Such as the production of complete feed in large feed plants and the mixing of basic chemical raw materials in large chemical companies.

Uniformity is as high as more than 99%, gentle mixing (degradation rate ≤0.1%), and compatible with CIP system. Low energy consumption, residual rate <5%, and ATEX explosion-proof options for explosive powders.

Versatility: V-type powder mixers are versatile and can handle a wide range of materials, including powders, granules, and even some pastes.

Easy to Clean: The design of the mixer allows for easy cleaning and maintenance, reducing downtime between batches.

Low Energy Consumption: These mixers are known for their energy efficiency, making them cost-effective for continuous use in industrial settings.

Scalability: V-type powder mixers come in various sizes, allowing for scalability to meet different production requirements.

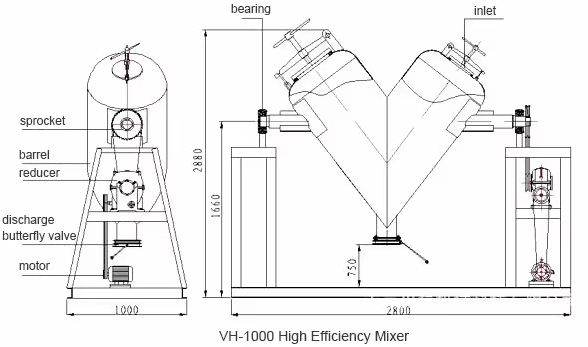

The V-type powder mixer consists of an asymmetrical twin-cylinder unit, a precision transmission system, and a sealed discharge mechanism. Made of 304/316L stainless steel with a polished interior, it achieves vertical and horizontal material flow through gravity diffusion and offset translation, achieving a mixing uniformity exceeding 99%.

V-Shaped Mixing Chamber: The mixer features a V-shaped chamber with two asymmetrically positioned cylinders that form a V shape. This design helps in efficient mixing and prevents material accumulation in the corners.

Rotating Mixing Blades: Inside the chamber, there are typically two or more rotating blades that move the material in a three-dimensional motion, ensuring thorough blending.

Drive System: The mixer is powered by an electric motor that drives the rotation of the mixing blades. The speed and direction of rotation can often be adjusted to achieve the desired mixing effect.

Discharge Valve: At the bottom of the chamber, there is a discharge valve that allows for easy removal of the blended material after mixing is complete.

The V-type powder mixer achieves mixing through a combination of "V-shaped chamber rotation + dynamic material convection." The core process revolves around the chamber's motion. After the equipment is started, a motor drives the V-shaped stainless steel chamber to rotate back and forth at a set speed. The powder inside the chamber continuously changes position with the chamber's motion. As the chamber rotates, the powder first converges at the V-shaped angle. Then, as the chamber rotates, it is divided into the two chamber arms, where it converges and divides again, forming a "division-convergence-convection" cycle.

Due to their high uniformity, cleanliness, and adaptability to small and medium-sized batches, V-type powder mixers are widely used in core mixing processes across multiple industries, providing efficient homogenization solutions.

Pharmaceutical Industry: When mixing active pharmaceutical ingredients with excipients, the V-shaped chamber's seamless rotation ensures uniform dispersion of the API, preventing uneven content that could affect efficacy. When preparing granules or capsule filling materials, drug powders can be thoroughly mixed with lubricants and disintegrants, improving the stability and dissolution rate of the finished formulation.

Food Industry: V-type powder mixers meet the homogenization requirements of various raw materials. When producing compound seasonings, they can precisely blend spices, salt, sugar, and other ingredients to avoid overly strong or weak flavors. When mixing baking ingredients, they ensure the thorough integration of flour, powdered sugar, leavening agents, and improvers, reducing dough mixing time and improving the taste and appearance of baked goods.

In the chemical industry: When mixing pigments or dyes, its circulating convection mode allows color powders of different particle sizes and specific gravities to fully blend, ensuring consistent color between batches. When adding plastic additives, it can evenly blend masterbatches, flame retardants, plasticizers, and other additives into plastic particles, improving the coloring effect and performance of plastic products.

In the agricultural industry: When producing feed additives, it can evenly blend trace ingredients such as vitamins, minerals, and enzymes into base feed powder, improving animal nutrient absorption and reducing waste.

| Type | Swept Volume(L) | Total Volume(L) | Mixing Power(kw) |

| VH-2 | 0.8 | 2 | 0.04 |

| VH-5 | 2 | 5 | 0.55 |

| VH-8 | 3.2 | 8 | 0.55 |

| VH-10 | 4 | 10 | 0.55 |

The V-type powder mixer offers a wide range of options. Available materials include 304 or 316 stainless steel, respectively meeting food-grade requirements and corrosion-resistant requirements in pharmaceutical and chemical applications. Additional features include liquid spraying devices and explosion-proof systems.

Variable frequency speed control device: The speed of the mixer is adjusted by changing the power supply frequency of the motor. The speed can be flexibly adjusted according to different material characteristics and mixing requirements to achieve the best mixing effect.

Heating/cooling device: For some powder mixing processes that require temperature, a heating or cooling jacket can be equipped to control the temperature of the mixing cylinder by circulating hot or cold media to ensure that the materials are mixed at a suitable temperature.

Vacuum system: It can evacuate the material during the mixing process to remove air and moisture from the material to prevent oxidation and moisture.

Spray device: During the mixing process, liquid additives such as adhesives and lubricants can be evenly sprayed into the material to fully mix the powder material with the liquid.Safety protection device: It includes emergency stop button, overload protection device, protective door switch, etc.

The price of the V-type powder mixer is affected by multiple factors. Equipment capacity is the key factor. The 50L small laboratory model has a relatively affordable price due to its small processing volume and relatively simple structure; while large industrial-grade models such as 300L have higher standards in material strength, power system, and processing technology to meet the needs of large-scale production, and the price is also increased accordingly. Differences in equipment configuration will also cause price fluctuations. For example, models equipped with automatic control systems, variable frequency speed regulation, and heating and cooling devices will have significantly higher prices than basic models. For specific model price lists, please contact us to obtain the latest price lists!

Dahan Machinery's mixers are customizable. The material-contacting parts are constructed of 304/316 stainless steel, with a polished interior that creates seamless surfaces. They are suitable for the pharmaceutical, food, and chemical industries. Fully customizable, the machine's height and capacity can be adjusted as needed, and liquid spraying devices, explosion-proof systems, and PLC control systems can be added. Flexible pricing is available, with bulk purchases starting as low as $1,350. Our products are sold worldwide, and we offer after-sales accessories and video inspection. Our products are exported to Europe, America, Southeast Asia, and other regions due to their high uniformity and stable performance. We provide customers with a comprehensive solution from selection to after-sales service.

The V-type powder mixer, with its unique dual-tube symmetrical structure and gravity diffusion principle, offers significant advantages in powder mixing. Its fully enclosed design effectively prevents cross-contamination. Its 304/316L stainless steel construction and precision polishing ensure durability and easy cleaning, making it particularly suitable for industries with stringent hygiene requirements, such as pharmaceuticals and food. By optimizing the vertical and horizontal material flow paths, this equipment achieves mixing uniformity exceeding 99% with a carryover rate as low as 0.5%, significantly improving efficiency and cost-effectiveness in high-value or small-batch production.

What materials are available for V-type powder blenders?

V-type powder blenders are primarily made of 304 and 316 stainless steel. 304 stainless steel contains chromium-nickel alloy, offering general corrosion resistance, while 316 stainless steel contains molybdenum, offering enhanced resistance to acid, alkali, and chloride corrosion.

Can V-type powder blenders mix special materials?

V-type powder blenders can be customized to meet customer needs to mix a variety of special materials. 316L stainless steel is suitable for mixing highly active pharmaceutical ingredients and corrosive chemical powders. Its fully enclosed structure and vacuum system enable it to handle materials such as graphite powder that are prone to flying and require contamination control.

Will V-type powder blenders cause lumps when mixing wet materials?

V-type powder blenders may cause lumps when mixing wet materials. This is because high-moisture materials tend to adhere to the mixer walls and form lumps, especially without auxiliary equipment. However, this can be improved with appropriate configuration.

How to choose between a V-type powder blender and a three-dimensional motion mixer?

The selection process should be based on the material characteristics and production requirements. V-type mixers are suitable for mixing small to medium batches of dry powders with small variations in specific gravity or particle size, achieving a mixing uniformity of approximately 98%. Three-dimensional motion mixers achieve seamless mixing through compound motion and are suitable for materials with large variations in specific gravity, containing liquids, or being fragile.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.