What is a Small mixer machine?

Small mixer machine is a compact device designed specifically for mixing small quantities of materials. Its compact size and ease of operation allow it to precisely process powders, granules, liquids, and pastes, meeting diverse needs such as small-batch production and formulation development, providing a stable and reliable mixing solution for precision processing.

Small mixer machines offer advantages: They are compact, space-saving, and easy to use. They are suitable for mixing small quantities, have low energy consumption, and deliver uniform mixing, providing a flexible and reliable mixing solution for laboratories and small factories.

Small size: Suitable for space-constrained locations such as laboratories and small workshops.

Low energy consumption: Power consumption is typically between 0.5 and 5 kW, saving over 30% energy compared to larger equipment.

Easy operation: Available with manual or automatic control, and easy cleaning and maintenance.

Versatile adaptability: Customizable materials include 304/316L stainless steel, and dust-proof and explosion-proof sealing.

High cost-effectiveness: Lower price than standard mixers, providing a rapid return on investment.

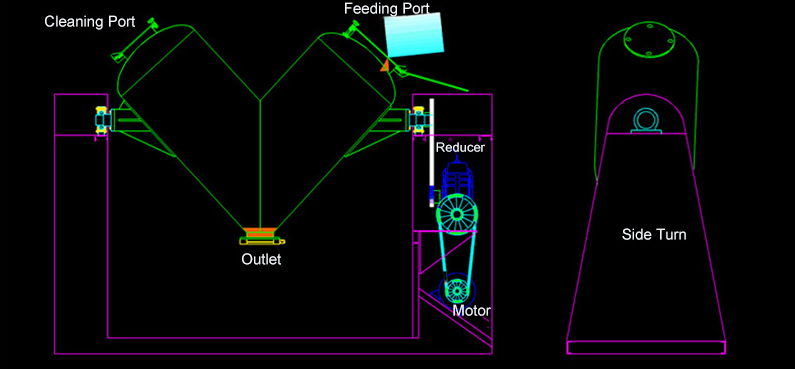

The core of a small mixer machine consists of three parts. Its overall structure is simple, utilizing the weight-induced drop and cross-mixing of materials generated by the rotating drum to achieve efficient and uniform mixing.

The small mixing drum: It is composed of two symmetrical, tilted cylinders welded into a V-shape, typically at an angle of 60°-90°. The inner wall of the drum is polished to reduce material residue and serves as the core mixing chamber.

The drive system: This system comprises a motor, a reducer, and a coupling. The drive shaft drives the V-shaped drum to rotate around the horizontal axis at a speed of typically 10-30 rpm, ensuring alternating turbulence within the drum.

Auxiliary components: The machine is equipped with an inlet and discharge valve. Some models also include a vacuum system or an inert gas port to accommodate specialized material mixing needs.

| Type | Swept Volume(L) | Total Volume(L) | Mixing Power(kw) |

| VH-2 | 0.8 | 2 | 0.04 |

| VH-5 | 2 | 5 | 0.55 |

| VH-8 | 3.2 | 8 | 0.55 |

| VH-10 | 4 | 10 | 0.55 |

A small mixer operates based on the principles of forced convection and shear mixing. When the motor is turned on, the agitator shaft rotates at high speed, and the mixing blades rotate accordingly, applying strong shear forces to the material, breaking up any agglomerates. At the same time, the blades of the small mixer machine propel the material into circulation within the container, creating convection currents that cause the materials to collide and mix at different locations, ultimately achieving uniform dispersion.

A small mixer machine can mix a wide variety of materials, including powders such as flour and seasonings, granules like feed and plastic pellets, liquids and pastes like sauces and cosmetics, and even corrosive, acid- and alkali-sensitive, and heat-sensitive pharmaceutical excipients.

Powders/Granules: Suitable for materials such as flour, feed, and plastic pellets, achieving a mixing uniformity of ≥95%. The machine's optimized mixing structure ensures sufficient convection and diffusion of powders and granules within a short period of time.

Pastes/High Viscosity: Designed for high-viscosity materials such as adhesives, cosmetics, sauces, and battery slurries, it utilizes a high-shear mixing element to break down material agglomerates and achieve a fine blend. An optional liquid spray system allows precise control of the liquid addition rate and mixing rhythm to prevent localized clumping.

Corrosive Materials: Made of chemically resistant 316L stainless steel, the machine ensures durability and material purity. Heat-sensitive materials: Equipped with low-temperature mixing capabilities, these machines prevent material deterioration caused by high temperatures, meeting the stringent process requirements of industries such as pharmaceuticals and fine chemicals.

Small mixer machines have been used across a wide range of sectors, from improving seasoning uniformity in food factories, accelerating R&D processes in laboratories, to optimizing feed ratios in livestock farms. They all enable fast and precise mixing.

Small food processing plants: Manual mixing of raw materials is inefficient and difficult to control, resulting in inconsistent product quality. The introduction of small mixers has significantly improved this situation, enabling the mixing of spice powders and granules of varying particle sizes at optimal speeds.

Research laboratories: Mixing small quantities of powders with varying properties and liquid reagents is a common requirement. Small mixers, with their high-precision mixing control and small mixing tanks, are an ideal choice. In developing new battery electrode materials, nano-sized metal oxide powders must be mixed with specific solvents in precise proportions. The mixer's ingeniously designed impellers achieve gentle mixing at low speeds, preventing powder agglomeration while ensuring full penetration of the liquid.

Small farms: Manually mixing pig feed was previously labor-intensive and time-consuming, and uneven mixing could affect pig growth and development. The introduction of small feed mixers has revolutionized this situation. The mixer's large capacity allows it to meet a farm's daily feed needs. Its unique spiral mixing blades thoroughly blend ingredients like cornmeal, soybean meal, and premix, ensuring nutritional balance in every bite.

Small mixers start as low as $500, with pricing influenced by various factors. Basic models with small capacity and simple functions are often used for mixing basic materials in laboratories, offering an affordable price and suitable for budget-conscious customers. Small mixer machine prices increase with larger capacities, such as up to 1500 grams, and with upgraded features like variable speed control, heating and temperature control, or higher-quality stainless steel. Customizing a special mixing mechanism to accommodate high-viscosity materials or specialized processes will also increase costs.

As a professional manufacturer with many years of experience in the small mixer field, we are renowned for our superior quality and innovative technology. Our factory is equipped with advanced production equipment, and our small mixer machines are made from high-quality stainless steel and other materials, ensuring product durability from the very beginning. Our R&D team continuously innovates, creating a variety of practical models with capacities ranging from 100 grams to 1500 grams. Each unit undergoes rigorous quality inspection before shipment to ensure stable performance. Whether you're mixing materials in the laboratory or needing small-batch production, we can provide customized solutions and tailor-make the right mixing equipment for you.

Mixed materials are a common need in many production and experimental scenarios, and small mixers have emerged as a crucial requirement. Designed specifically for mixing small quantities of materials, they play a key role in various fields thanks to their unique advantages.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.