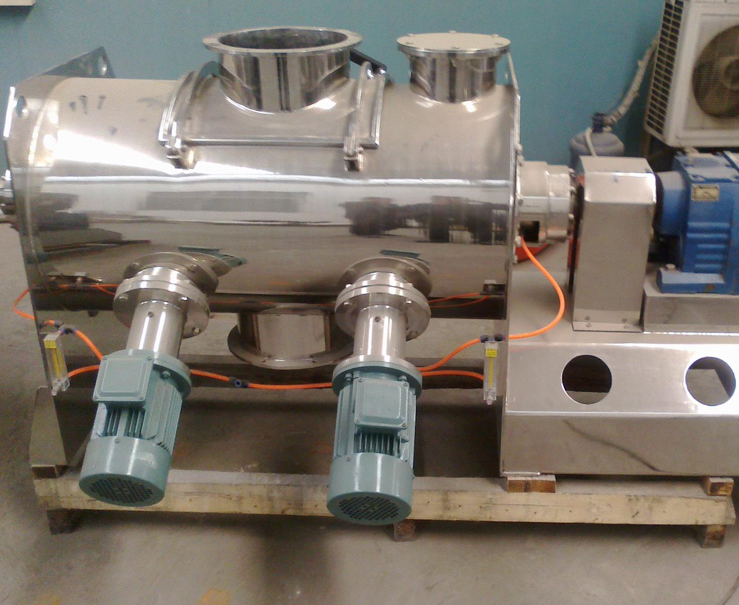

As a key device for achieving uninterrupted material mixing, the Continuous mixer process follows a closed-loop design of "continuous feeding - dynamic mixing - stable discharging." It is suitable for the large-scale continuous production needs of industries such as chemicals, building materials, and food. An intelligent control system adjusts parameters such as speed and mixing ratio in real time throughout the process to ensure mixing uniformity and production efficiency. Compared to batch mixers, it offers advantages such as high production capacity, low energy consumption, and a high degree of automation.

The continuous mixer, with its high-speed, continuous production process, offers significant advantages in modern production. Compared to traditional batch mixers, it enables uninterrupted feeding, mixing, and discharging, making it particularly suitable for large-scale continuous production.

24-hour non-stop operation: The continuous mixer's flow-through design ensures uninterrupted material flow from feeding to discharging, resulting in 40%-60% higher efficiency than traditional batch mixers.

Dynamic mixing and instant adjustment: The PLC control system monitors material flow in real time, enabling millisecond-level adjustments to mixing parameters. Precise temperature and pressure control: In chemical applications, the mixing chamber is equipped with a double-jacket cooling system, which uses thermal oil circulation to control temperature fluctuations within ±1°C.

Energy consumption is reduced by 20%-30%: Variable frequency speed regulation technology matches the actual load, significantly saving energy compared to fixed-speed equipment.

Raw material loss is reduced by 15%: The precise metering system and anti-stick coating technology work together to reduce material residue.

The process flow of a continuous mixer can be divided into four core stages, each of which is dynamically balanced by a precision control system.

Intelligent batching stage: Using electronic scale reduction-based metering technology, aggregates, powders, and liquid additives are controlled with an accuracy of ±0.5% through independent metering hoppers.

Synchronous conveying stage: Conveying equipment is activated sequentially based on the distance from the mixer inlet, creating a "time difference compensation" mechanism.

Compound mixing stage: The built-in planetary motion blade assembly generates a spiral-cycloidal composite trajectory through three-axis linkage, creating a three-dimensional turbulent flow field within the mixing drum. For special concrete with viscosities up to 5000 cPs, the blades generate a shear force of 12 kN at a speed of 120 rpm. This, combined with the vibration module in the diversion pipe, effectively prevents high-viscosity materials from sticking.

Continuous discharge phase: The finished product is discharged through a pipe whose inner wall is coated with a nano-ceramic coating to reduce friction.

The core breakthrough in the continuous mixer process lies in the application of intelligent dynamic control technology. High-precision sensors monitor material conditions in real time, combined with AI algorithms to automatically optimize mixing parameters, achieving a new industry standard of mixing uniformity of ±1%.

Intelligent dynamic mix correction system: A high-precision PLC monitors the mixer's current curve in real time and, combined with a machine learning algorithm, predicts material viscosity changes. If excessive current fluctuations are detected, the system automatically adjusts the admixture dosage to ensure that the concrete slump remains within a stable range of 180 ± 10 mm.

Modular explosion-proof safety system: A three-level protection system specifically designed for flammable and explosive working conditions. All electrical components comply with ExdIICT4 explosion-proof standards. The mixing drum has a grounding resistance of ≤0.1Ω and is equipped with an ionizing air bar to eliminate static electricity. A temperature safety interlock automatically activates nitrogen protection when the chamber temperature exceeds 60°C.

Intelligent wear compensation mechanism: The blade's integrated strain gauge sensor monitors wear in real time. When blade thickness loss exceeds 3mm, the system automatically implements a compensation strategy: increasing the speed by 15%, extending the mixing time by 20 seconds, and simultaneously issuing a replacement warning.

In industrial continuous production scenarios, continuous mixers must work effectively with various conveying equipment to build a complete "raw material conveying - mixing - finished product transfer" production line. Inclined screw conveyors, Z-belt conveyors, and bucket elevators, with their differentiated conveying advantages, have become core supporting equipment for continuous mixers.

Continuous mixer + inclined screw conveyor: This combination offers the core advantages of enclosed conveying and a small footprint. It is suitable for close-range, 5°-45° inclination feeding of raw materials and conveying of finished products. It is particularly suitable for fine materials such as flour and chemical powders that are prone to dust or require pollution control.

Continuous mixer + Z-belt conveyor: This combination, with its wide-angle climbing and flexible routing, can handle sites with large height differences and obstacles. It can handle granular, small, and mixed materials such as feed pellets and building material aggregates.

Continuous mixer + bucket elevator: This combination offers the advantages of vertical conveying, a small footprint, and high height. It is ideal for vertically elevating raw materials or finished products and is suitable for a variety of materials, including cement and ore pellets.

Continuous mixers, with their continuous process flow, are demonstrating their exceptional value across multiple industries. Through three case studies, we will demonstrate how continuous mixers, through intelligent proportioning control, explosion-proof safety design, and precise mixing technology, can help companies improve production efficiency, ensure production safety, and achieve breakthrough improvements in product quality.

Building materials industry: The adoption of intelligent continuous mixers successfully resolved the problem of concrete slump fluctuations caused by traditional batch mixing. By integrating a dynamic proportioning correction system, the equipment monitors current changes in real time and automatically adjusts the water-reducing agent flow rate, improving mixing uniformity by 40% and increasing daily production to over 800 tons.

Chemical industry: Titanium dioxide modification companies faced serious safety challenges in the mixing of flammable powders. The introduction of modular explosion-proof continuous mixers, with their three-level explosion protection system and nitrogen protection mechanism, completely eliminated the risk of explosions, achieving zero accidents throughout the year.

Food industry: A compound seasoning manufacturer reduced batching error from ±5% to ±0.3% by deploying an AI-driven continuous mixer, completely resolving batch stability issues. The intelligent transformation reduced customer complaints by 90% and reduced labor costs by 70%, enabling 24-hour unmanned production.

Continuous mixers achieve stable and efficient large-scale production through automated feeding, rapid mixing, and continuous discharging. Widely used in industries such as chemicals, food, and building materials, they are essential equipment in modern industrial production. Choosing the right continuous mixer can significantly improve production efficiency and product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.