Feed for single shaft horizontal mixer has a single shaft running through the horizontal barrel and is equipped with spiral stirring blades or ribbons. After startup, the single shaft drives the stirring assembly to rotate at a constant speed, which can quickly turn and push a variety of feed ingredients such as corn flour, soybean meal, and mineral premixes, achieving dual axial and radial mixing. The equipment volume is mostly suitable for mixing needs of 50-1000kg/batch. The unloading adopts a bottom-opening design, and the residue rate is as low as below 0.5%, which perfectly meets the cost and production capacity requirements of small and medium-sized feed processing.

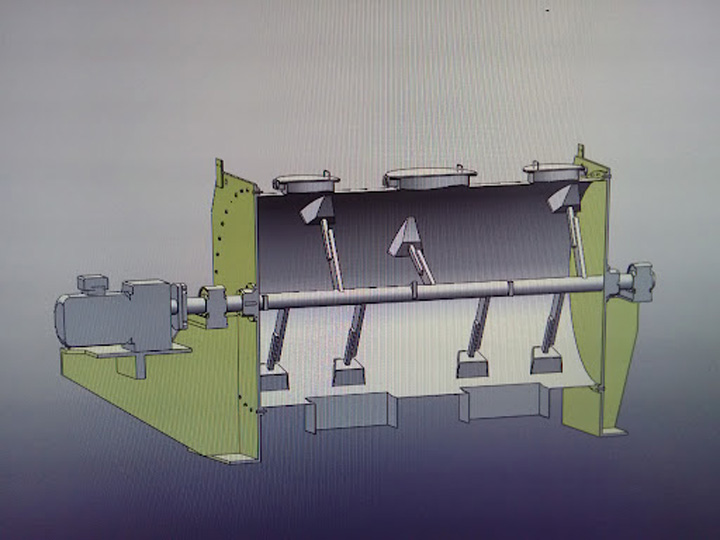

Composition structure of feed for single shaft horizontal mixer is an important part of the whole mixing process, and its structure directly affects the uniform mixing of materials and production efficiency. Let's take a closer look at the composition structure of feed for single shaft horizontal mixer.

Main structure: usually composed of frame, mixing barrel, transmission system, feed port, discharge port and other parts.

Stirring device: single shaft agitator or blade, used to mix raw materials.

Transmission system: including motor, reducer, etc., to provide power for the agitator.

feed for single shaft horizontal mixer the mixer connects to a conveyor or hopper through a top feed port, and raw materials enter the horizontal drum at a set rate. During the feeding process, the single-shaft agitator operates synchronously at a low speed to initially disperse the material, preventing accumulation and blockage, and laying the foundation for subsequent uniform mixing.

Starting equipment: the motor drives the agitator to rotate in the mixing barrel.

Feeding: various feed raw materials are added to the mixing barrel through the feed port.

Mixing: The mixer continuously mixes and turns the feed raw materials in the mixing barrel to achieve uniform mixing of the raw materials.

Discharging: After mixing, open the discharging port and take out the mixed feed.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Feed for single shaft horizontal mixer The single shaft horizontal mixer takes the single shaft mixing structure as its core, with a refined structure and simple maintenance. It is suitable for multi-form materials such as powders and granules, with smooth feeding without material blockage and flexible material selection.

Even mixing: The mixer is reasonably designed and can fully mix various feed raw materials to ensure uniform ratio.

Easy operation: The structure is simple, easy to operate, easy to clean and maintain, and saves labor costs.

High efficiency and energy saving: The mixing effect is good, and the mixing process can be completed quickly, saving time and energy consumption.

Improve feed quality: Even mixing can ensure that various ingredients in the feed are fully mixed, and improve the quality and nutritional balance of the feed.

Wide range of applications: Feed for single shaft horizontal mixer is suitable for mixing various feed raw materials to meet the feeding needs of different animals, and is widely used in livestock and poultry farming, aquaculture and other fields.

Feed for single shaft horizontal mixer and a feed for single shaft vertical mixer are two common feed mixing equipment. The main difference lies in the different structural forms, floor space and applicable scenarios:

| Types |

feed for single shaft horizontal mixer |

feed for single shaft vertical mixer |

| Structure | The main shaft is placed horizontally, the whole machine is a horizontal structure, and the interior of the mixing barrel is usually U-shaped or trough-shaped. | The main shaft is placed vertically, the whole machine is a vertical structure, and the interior of the mixing barrel is usually cylindrical. |

| Mixing method | The mixing blades are fixed on the main shaft, and mixing is achieved by the rotation of the main shaft. The mixing effect mainly depends on the stirring action of the blades. | The mixing blades are fixed on the main shaft, and mixing is achieved by the rotation of the main shaft. The mixing effect mainly depends on the stirring action of the blades. |

| Scope of application | It is suitable for mixing granular or powdered feed raw materials, simple operation, easy to clean and maintain. | It is also suitable for mixing granular or powdered feed raw materials, with good mixing effect, and is suitable for some special mixing processes. |

| Space occupied | Relatively large, requiring a certain site layout. | Relatively small, suitable for use in limited space. |

Feed for Single Shaft Horizontal Mixers this mixer has a wide range of applications in the feed industry. Its design features make it particularly suitable for processing a variety of feed ingredients, ensuring uniform mixing and efficient production.

Premix Production: The propeller design achieves high-precision mixing, ensuring uniform dispersion of trace ingredients such as vitamins and minerals, preventing stratification and clumping. Its low-shear characteristics provide gentle mixing, maximizing the nutritional activity of heat-sensitive ingredients.

Complete Formula Feed Production: The horizontal structure, equipped with a large-capacity mixing chamber, is suitable for continuous processing of ingredients such as corn and soybean meal, meeting the production capacity needs of large-scale farms. The propeller's forced agitation ensures thorough mixing of pellets and powder, eliminating local nutrient deviations.

Ruminant Diet Production: For TMR diets for dairy and beef cattle, the propeller's pushing action breaks down long fibers while maintaining their structural integrity, promoting rumination. The uniformity of the horizontal mixer prevents feed stratification, ensuring consistent nutrition in every bite, and improving animal feed intake and digestibility. Pet feed production: The low-speed design gently mixes diverse ingredients such as meat and vegetables, minimizing particle breakage and preserving the natural taste and shape of pet food. The equipment supports the uniform addition of liquid ingredients, meeting the needs of high-end formulations.

Specialty feed production: For applications such as aquatic feed and young animal feed, where uniformity is crucial, the single-shaft mixer achieves precise mixing of various formulations by adjusting mixing time and speed. The single-shaft design simplifies cleaning, prevents cross-contamination, and supports rapid production switching between multiple varieties.

Mixing feed additives and carriers: Gentle mixing technology reduces friction between additives such as enzymes and probiotics and mechanical components, preventing loss of activity. The equipment ensures uniform mixing of additives and carriers, ensuring consistent ingredient content per gram of feed, improving feed performance.

We are a company integrating R&D, production, and sales of feed equipment, specializing in single-shaft horizontal mixers for over a decade. Our products feature high-speed mixing, low energy consumption, and durability. Utilizing a high-strength propeller and optimized transmission design, they precisely process powders, pellets, and crude fiber, achieving a uniformity of over 98%. We offer customizable services, adjusting the mixing chamber capacity, speed, discharging method, and material to meet customer needs. We also integrate modules for liquid addition and temperature control, making them suitable for diverse production scenarios such as premixes, ruminant feed, and pet food.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.