Chemical powder ribbon mixer uses double-screw reverse stirring technology to achieve three-dimensional efficient mixing. The main body is made of 304/316L stainless steel, which has both corrosion resistance and easy cleaning characteristics. It is suitable for mixing powders, particles and liquids. It can be equipped with explosion-proof, temperature control and intelligent PLC systems. It saves more than 30% energy than traditional equipment, improves mixing efficiency by 50%, and supports 100-10000L customized services.

Double-screw three-dimensional mixing, uniformity CV≤3%, suitable for 1μm-3mm powder, supports liquid-solid mixing and temperature control, and helps chemical industry to be highly efficient and homogenized!

Fast mixing: the CV value of mixing uniformity is ≤5%, which is much better than the 10%-15% of traditional V-type mixers.

High processing capacity: the processing capacity can reach 10t/h (taking calcium carbonate as an example), which is more than 30% higher than that of conical double-screw mixers.

Wide application: suitable for powders with a particle size of 20-1400 mesh, and the spray volume can be accurately controlled within the range of 0.1%-5%.

Precise temperature control system: jacketed heating/cooling design, supporting electric heating (up to 300℃) and thermal oil heating (heating speed increased by 40%).

Low energy consumption and easy maintenance: using cycloid pinwheel reducer direct drive, the transmission efficiency is more than 95%, which saves 20% energy compared with gear transmission.

Reduce pollution: pneumatic discharge valve design, residual volume ≤0.5%, reducing the risk of cross contamination.

The working principle of chemical powder ribbon mixer is based on multiple synergistic mechanisms: the double spiral convection mechanism pushes the material from the axis to the outside through the inner spiral, and the outer spiral reverses the material to the center, forming a three-dimensional convection, so that the material can quickly reach high uniformity; the axial circulation strengthening mechanism uses the spiral blades to push the material to rise along the cylinder wall and fall back axially at the top, forming a forced circulation, effectively eliminating the mixing dead corner and avoiding the stratification of materials with large density differences.

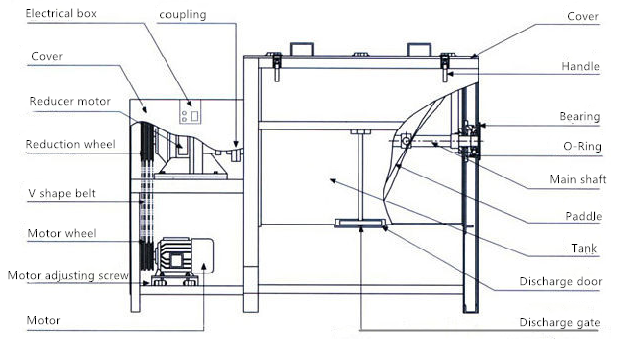

It is composed of double spiral ribbon stirring paddles, U-shaped stainless steel cylinders, variable frequency drive systems, intelligent control modules and other components to achieve efficient powder mixing and safe production.

Spiral ribbon stirring paddle: adopts an inner and outer double-layer spiral steel belt structure, the outer spiral ribbon pushes the material axially (from both ends to the middle), and the inner spiral ribbon pushes in the opposite direction (from the middle to both ends), forming a three-dimensional convection mixing.

Stirring shaft: solid shaft design, the diameter matches the cylinder volume (usually 50-150mm), and is connected to the spiral ribbon by welding or bolts to ensure strength and stability during high-speed rotation.

U-shaped cylinder: formed by rolled plate welding, volume specification 50-5000L, smooth inner wall without dead angle; bottom inclination angle ≤3°, with large door discharge port.

Drive motor: standard three-phase asynchronous motor, power configuration according to volume (2.2-37kW).

Speed reducer: gear reducer or cycloidal pinwheel reducer, transmission ratio 10-50:1, stable output torque.

Feed inlet: flange feed inlet is set at the top, which can be connected to screw conveyor, vacuum feeder, etc.;

Discharge port: pneumatic/electric discharge valve is set at the bottom center, the gate material is wear-resistant stainless steel, the switching time is ≤5 seconds, and the guide groove is used to reduce material residue.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

This equipment can meet more than 90% of industrial mixing needs through modular design. It is recommended to provide material samples for process verification before actual application. We provide free material adaptability testing services to ensure that the equipment selection accurately matches your production requirements.

Powder + powder mixing: specially designed for fine powder mixing, typical applications include pigments and fillers (such as titanium dioxide + calcium carbonate), pharmaceutical raw materials (API + excipients) and battery materials (positive electrode powder + conductive agent), etc. The equipment has significant advantages, with a mixing uniformity coefficient of variation CV≤3%, and can handle powder materials with a fineness range of 1μm-3mm.

Powder + liquid mixing: supports a variety of liquid additions, such as adhesives (PVA solution), wetting agents (silicone oil), reaction liquids (catalyst solutions), etc. The key technology uses an atomization spray system, the droplet size is controlled at 50-200μm, and the maximum liquid addition amount can reach 15% of the material weight.

Powder + particle mixing: suitable for materials with a wide particle size range, powder particle size 1-500μm, particle size 0.5-5mm. Typical cases include plastic masterbatch (color powder + PE particles), feed additives (vitamin powder + carrier particles), etc.

Powder + paste mixing: For paste materials with a viscosity of 5,000-50,000cP, reinforced spiral blades and side wall scrapers are configured to solve the adhesion and mixing problems of high-viscosity materials. Applicable to inks, ointment bases, sealants and other fields.

This equipment is optimized by CFD fluid dynamics design, saving more than 30% energy compared with traditional mixers.

Batch cycle time: The conventional material mixing cycle is 5-15 minutes/batch, and the optimization effect is significant: titanium dioxide mixing only takes 8 minutes (12 minutes shorter than traditional equipment), and lithium battery material mixing (including inert gas replacement process) takes 12 minutes, greatly improving production efficiency.

Mixing uniformity: Under standard mixing level, the coefficient of variation (CV value) can be controlled at 3%-5%; after process optimization, the mixing uniformity of special formulas can reach CV≤1.5%. The sampling analysis method is used for detection, and at least 5 sampling points are set for each batch to ensure the consistency and reliability of mixing quality.

Volumetric efficiency: The effective volume ratio of the equipment is 60%-75%. The specific value is adjusted according to the bulk density of the material, which can meet the batch mixing requirements under different working conditions, taking into account the space utilization and mixing effect.

To select a suitable chemical powder ribbon mixer, you need to consider multiple dimensions such as material characteristics, production requirements, and equipment performance. The following are specific screening points and suggestions.

Material characteristics and equipment adaptation: Clarifying the basic characteristics of the material is the key to selecting a chemical powder ribbon mixer. First, you must determine the material state and mixing type. At the same time, you must understand the physical and chemical properties of the material, including particle size and fineness, corrosiveness/wear resistance, heat sensitivity/flammability and explosiveness.

Production scale and equipment volume: Production scale and efficiency requirements directly affect equipment selection. The equipment volume is determined according to the mixing amount of a single batch, and the conventional effective volume ratio is 60%-75%. The conventional material mixing cycle is 5-15 minutes/batch. In pursuit of high efficiency, you need to choose a high-speed motor and a double-ribbon structure.

Mixing system and speed control: Mixing system design is crucial to mixing efficiency. The double-layer ribbon structure is 30% more efficient than the single-layer structure and is suitable for materials with large particle size differences; reinforced spiral blades and sidewall scrapers are required to handle high-viscosity pastes.

Additional functions and automation integration: Select additional function modules according to actual needs. The temperature control system is suitable for reaction mixing that requires temperature control, with a temperature control accuracy of ±2℃; the liquid addition device needs to confirm the metering pump accuracy and maximum addition amount; in terms of automation integration, the PLC control cabinet supports formula storage and MES docking, which is suitable for large-scale production.

The price span of chemical powder ribbon mixers is large. Small and simple models (less than 50KG, mostly made of ordinary carbon steel or 201 stainless steel) are mainly used in laboratories or small workshops, with a lower price of about US$85-690. Conventional industrial type (50KG - 1000KG, material is usually 304 stainless steel) can meet the general chemical powder mixing needs, with basic mixing and some additional functions, the price is usually 1000-5000 US dollars. The specific price will be quoted according to your detailed needs. If you need it, you can contact us at any time to get a detailed quotation!

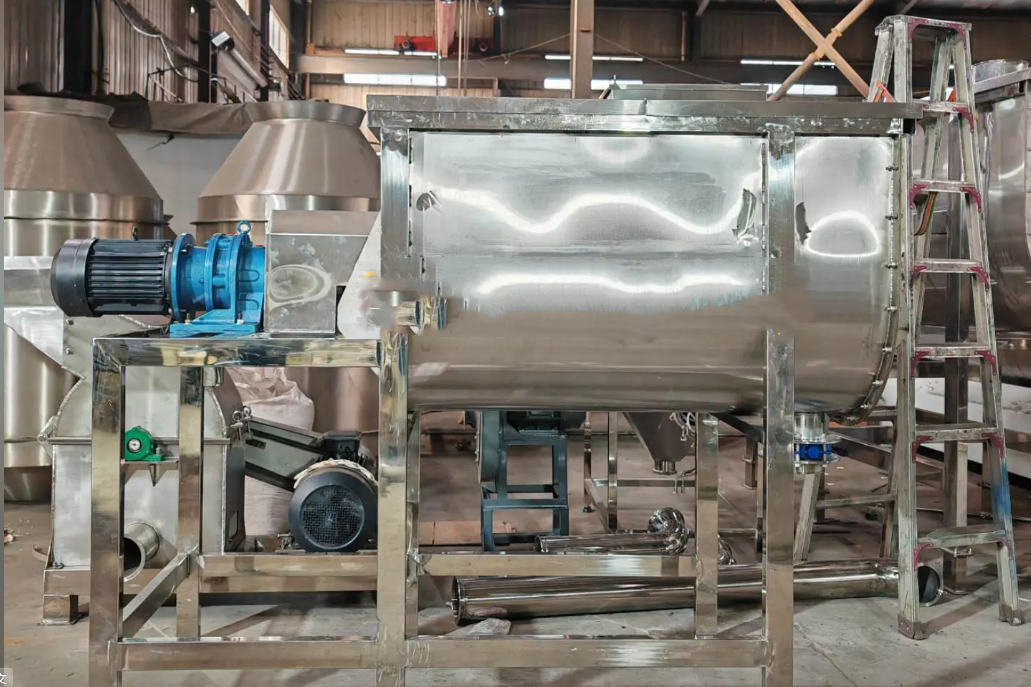

As a professional chemical powder ribbon mixer manufacturer, Dahan Machinery has been focusing on the research and development and manufacturing of high-efficiency mixing equipment for more than 10 years. We use 316L stainless steel ribbon components and provide a full range of customized equipment from 100 to 20000L, covering explosion-proof, vacuum, heating and other configurations. The products have been successfully applied by many companies and exported to many countries. We ensure that each equipment has an ultra-long service life, and provide free material trial mixing services to provide you with customized production services.

Chemical powder ribbon mixers have become the preferred equipment in the field of powder mixing due to their high efficiency, stability and safety. Whether it is fine chemicals or large-scale production, we can provide customized solutions to help companies improve product quality and production efficiency!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.