Stainless steel ribbon mixer is a high-speed mixing equipment designed for powder, granular and paste materials. It is made of 304/316L stainless steel and has the characteristics of corrosion resistance, easy cleaning and high mixing uniformity. Its unique double-ribbon reverse mixing structure can achieve three-dimensional mixing, ensuring that the material reaches a high degree of uniformity in a short time and meets the needs of industrial production.

Stainless steel ribbon mixers are divided into two types: vertical and horizontal. The difference in their structure directly affects the application scenarios.

Vertical stainless steel ribbon mixer: It adopts a vertical barrel design. The ribbon spirals up around the central axis. Under the force of gravity and the ribbon, the material is lifted up along the barrel wall and then falls from the center to form a circulating convection mixing. This model occupies a small space and is suitable for small production scenarios or laboratory research and development. It can handle materials with good fluidity, such as some food additives, dry powdered chemical raw materials, etc.

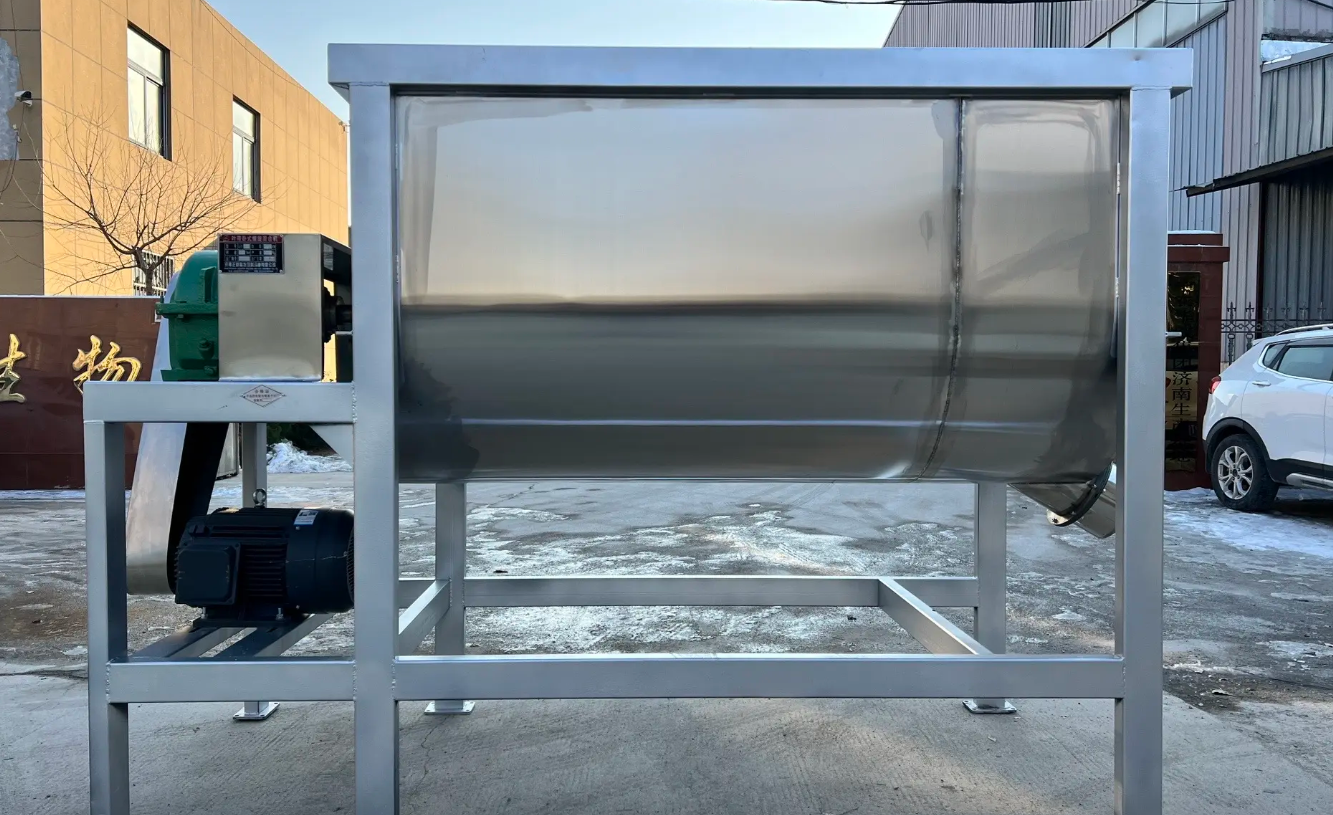

Horizontal stainless steel ribbon mixer: Based on a horizontally placed U-shaped cylinder, it is equipped with inner and outer double-layer ribbons. The outer ribbon pushes the material to move axially, and the inner ribbon conveys in reverse to form strong convection, realizing three-dimensional mixing of materials. The horizontal model has high mixing efficiency and good uniformity, and can handle large batches of materials with large density differences or high viscosity, such as pharmaceutical particles, high-concentration coating powders, etc.

This stainless steel ribbon mixer uses medical-grade 316L material, and achieves dead-angle mixing through double-ribbon reverse mixing, and supports explosion-proof/sterile customization.

Low shear force: Through the reasonable gap design between the ribbon and the cylinder wall (usually 5-10mm), low shear force mixing is achieved to avoid material particle crushing or fiber breakage, especially suitable for fiber-containing foods or easily agglomerated powders.

Clean and hygienic: The equipment is made of 304 or 316L stainless steel. 304 is suitable for general corrosive environments (such as food and beverage industries), while 316L contains molybdenum, which has better resistance to pitting and crevice corrosion and is suitable for high-salt and high-chlorine environments. Long service life: The corrosion resistance of 316L stainless steel in chlorine-containing media is more than 3 times that of 304, and the equipment life can reach more than 10 years, significantly reducing replacement costs. .

Can mix a variety of materials: The equipment can handle materials with a viscosity range of 1-1,000,000cP, from low-viscosity liquids (such as juice) to high-viscosity pastes (such as chocolate), and supports high-solid content mixing (such as mortar solid content of 80%)

Customized design: The equipment can be equipped with a vacuum system to realize vacuum degassing or drying process; equipped with a weighing module and a liquid level sensor to realize automated production control. In addition, special materials (such as Hastelloy), explosion-proof configurations or special sealing structures can be customized according to customer needs.

We offer two kinds of stainless steel ribbon mixers: 304/316L. 304 is suitable for general corrosive environments, while 316L is more acid-resistant and alkali-resistant, and is specially used for high-salt and high-humidity working conditions.

304 stainless steel: Due to its good corrosion resistance and economy, it is widely used in the food and pharmaceutical industries for mixing low-corrosive materials (such as syrup, juice, and sauce), meets food-grade hygiene standards, and performs well in the treatment of neutral or weakly acidic media (such as water-based paints and detergents) in general chemical industries, and is especially suitable for cost-sensitive projects.

316 stainless steel: Due to the addition of molybdenum, it has stronger corrosion resistance and is suitable for highly corrosive environments (such as seawater desalination, salt chemicals, and electroplating liquid mixing) and high-temperature and high-pressure working conditions (such as pharmaceutical sterilization tanks and high-temperature paint mixing). Its pitting and intergranular corrosion resistance are significantly better than 304. In addition, 316 stainless steel is also widely used in medical devices and bioengineering.

The stainless steel ribbon mixer achieves efficient mixing by generating three-dimensional compound motion through the reverse rotation of double ribbons: the outer ribbon drives the material to flow axially at a linear speed of 0.8-1.5m/s, and the inner ribbon rotates in the opposite direction to form shear convection. With the baffle, the material forms an "∞"-shaped circulation trajectory in the cylinder, completing 8-12 times/minute three-dimensional tumbling.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

| Model | Speed | Power | Dimension | Diameter x Height |

| 50 KG | 40 RPM | 0.75 KW | 800*780*980 | 780*420 |

| 75KG | 40 RPM | 1.5KW | 950*900*980 | 900*420 |

| 100 KG | 40 RPM | 1.5 KW | 1050*1000*980 | 1000*420 |

| 150 KG | 40 RPM | 2.2 KW | 1150*1100*980 | 1100*420 |

| 200 KG | 40 RPM | 3 KW | 1250*1200*1080 | 1200*490 |

| 250 KG | 40 RPM | 4 KW | 1350*1300*1100 | 1300*490 |

| 400 KG | 40 RPM | 5.5 KW | 1450*1400*1300 | 1400*560 |

| 500 KG | 40 RPM | 7.5 KW | 1550*1500*1400 | 1500*560 |

This machine is designed for multi-materials and can mix powders, particles, liquids and high-viscosity pastes!

Powder and powder mixing: widely used in chemical, food, medicine, building materials and other fields. Two different powders can be fully mixed and mixed to ensure the sanitation of the materials.

Powder and particle mixing: mainly serves feed, plastic processing, battery materials and other industries. It can mix and mix two different shapes of materials, powder and particles, and fully mix to ensure the uniformity of the mixing.

Mixing of powder and liquid: plays an important role in binder addition, food seasoning, pharmaceutical granulation and other links. Powder and water-based solvent are mixed in ceramic glaze production; spice powder and oil spraying are completed during food seasoning.

Mixing of high-viscosity pastes: focuses on industries such as cosmetics, adhesives, and food sauces. It is used for mixing foundation cream and lipstick matrix in cosmetics production; the adhesive industry is suitable for high-viscosity materials such as silicone sealants and epoxy resins; when making food sauces, chocolate paste, jam, etc. are uniformly mixed.

As a professional manufacturer who has been deeply involved in the field of mixing equipment for many years, we have become the preferred supplier of 3000+ companies with patented technology and ISO/CE/full system certification. The 304/316L stainless steel ribbon mixer (accuracy ±0.1mm) manufactured with precision technology can achieve industry-leading uniformity of CV≤3%, support full-series customization from 100L to 20 tons (explosion-proof/sterile/temperature control, etc.), and pass 72 hours of rigorous testing to ensure an ultra-long life of 100,000 hours. We provide a global service system with 24-hour response and lifelong maintenance. Typical customer cases show that the mixing efficiency can be improved by more than 50%. We sincerely invite you to visit and enjoy the free trial service!

The stainless steel ribbon mixer has become an ideal choice for powder processing in various industries with its advantages of efficient mixing, durable corrosion resistance, and intelligent control. It supports fully customized services and helps companies improve product quality and production efficiency!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.