Bulk Material Industrial Mixer designed specifically for powders, granules, and slurries, serves as a crucial link between raw materials and finished products due to its powerful processing capacity and precise mixing performance. Addressing the characteristics of large batches, diverse types, and continuous operation of bulk materials, the Industrial dry powder mixer employs a horizontal cylinder and rapid mixing structure, enabling large-scale mixing within a volume of 1-50 m³. Forced convection circulation breaks down material stratification and agglomeration, controlling the coefficient of variation in mixing uniformity to ≤5%. It can easily mix non-corrosive building sand and gravel, dry mortar, food-grade flour and protein powder, as well as corrosive powders used in the chemical industry.

Our Bulk Material Industrial Mixer can be customized to suit the characteristics of bulk materials, such as viscosity, particle size, and corrosivity, including mixing speed, discharge method (side discharge, bottom discharge), and auxiliary devices. For bulk materials with poor flowability, vibration devices can be added or the screw angle optimized to ensure smooth feeding and mixing. Standardized interfaces are provided for seamless integration with automatic feeders, screening machines, packaging machines, and other upstream and downstream equipment, enabling fully automated operation from raw material input to finished product packaging, significantly reducing labor costs.

The core material selection for the Bulk Material Industrial Mixer revolves around adapting to material characteristics and industry standards. Both of our offered materials are customizable and can be flexibly combined according to the material contact areas.

Carbon Steel: As an economical and practical basic choice, it is suitable for non-corrosive bulk materials without special hygiene requirements, such as construction sand and gravel, dry mortar, and common feed ingredients. The material has high strength and controllable cost, meeting the needs of large-scale mixing of bulk materials.

Stainless steel material: Primarily focused on corrosion resistance and hygiene, it is divided into two main types: 304 stainless steel and 316L stainless steel. 304 stainless steel is suitable for food-grade materials and mildly corrosive chemical powders, is easy to clean, leaves no residue, and avoids material contamination. 316L stainless steel offers stronger corrosion resistance and is suitable for highly corrosive bulk materials, resisting material erosion of equipment and extending its service life. It is the preferred material for high-requirement chemical and pharmaceutical industries.

The core advantage of a Bulk Material Industrial Mixer lies in its ultra-large processing capacity and high-speed mixing performance. Designed for large batches of bulk materials requiring continuous operation, the equipment's cylinder volume can be customized from 1-50m³, with a single mixing capacity covering several tons to tens of tons, easily meeting the production capacity requirements of large-scale production. It adopts efficient mixing structures such as double-ribbon, paddle, or plow-type mixers, using a motor-driven forced convection circulation to control the coefficient of variation of uniformity of bulk materials with different specific gravities and particle sizes to ≤5%, ensuring consistent composition and stable performance in each batch of product.

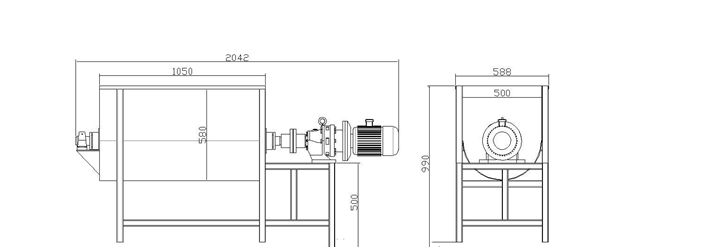

The core structure of the Bulk Material Industrial Mixer is designed around stable support, rapid mixing, smooth feeding and discharging, and safe control. All components work together to achieve large-scale, uniform mixing of bulk materials.

Frame and Drum: The frame provides stable support for the entire equipment and is welded from carbon steel to ensure stability when handling large volumes of bulk materials. The drum is the core mixing area, with a horizontal structure; its volume can be customized, and the material is selected based on the material characteristics, using either carbon steel or stainless steel.

Mixing System: The core power component, consisting of a motor, reducer, mixing shaft, and mixing blades. The motor provides power, and the speed is regulated by the reducer. The mixing shaft runs through the drum, and a double-layer spiral ribbon or special blades are installed on the shaft. The outer spiral ribbon pushes the material towards the center, while the inner spiral ribbon disperses the material to both sides, forming a forced convection circulation.

Feed Inlet: The feed inlet is usually located at the top of the drum, equipped with a dust cover or an interface for connecting to an automatic feeder. Some models are equipped with a feed hopper and control valve for easy adjustment of the feeding speed.

Discharge port: Located on the side or bottom of the cylinder, equipped with gate valves, butterfly valves, and other control components, it allows for the rapid and smooth discharge of mixed materials.

The Bulk Material Industrial Mixer achieves homogeneous mixing through a closed-loop process of feeding - forced mixing - discharging. During operation, bulk materials enter the horizontal sealed cylinder through the top inlet. The motor drives the reducer to rotate the mixing shaft. The double-layer spiral ribbon on the shaft creates forced convection: the outer spiral ribbon gathers the material from both sides of the cylinder towards the center, while the inner spiral ribbon disperses the material in the center to both sides, causing materials with different properties to tumble and cross-mix rapidly within the cylinder. During mixing, the sealing structure prevents dust leakage, and the wall scraping device reduces residue on the cylinder wall. After homogeneous mixing, the mixture is discharged through the side or bottom outlet.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Bulk material industrial mixers can mix bulk materials from various industries, suitable for powders and granules, meeting the needs for uniform mixing of bulk materials with different specific gravities and particle sizes.

Building Materials Industry: Used for mixing bulk materials such as dry mortar, putty powder, and insulation materials, ensuring the bonding strength and insulation performance of building materials.

Chemical Industry: Processes bulk powders such as pigments, plastic additives, and fertilizers, ensuring uniform product composition and stable performance.

Food Industry: Suitable for large-scale mixing of materials such as flour, starch, and feed premixes, meeting food hygiene standards and production capacity requirements.

Feed Industry: Uniformly mixes bulk raw materials such as corn flour, soybean meal, and vitamins to produce nutritionally balanced livestock, poultry, and aquatic feed.

Choosing the right Bulk Material Industrial Mixer hinges on precise matching based on three core dimensions: material characteristics, production needs, and industry standards. Blindly selecting a model can lead to poor mixing results or wasted production capacity.

Based on material characteristics, identify core parameters: Prioritize material type (powder, granules, materials with a small amount of viscosity, etc.), corrosiveness (non-corrosive/slightly corrosive/strongly corrosive), moisture content, and mixing uniformity requirements. For non-corrosive materials, economical carbon steel models are suitable; for food-grade or slightly corrosive materials, 304 stainless steel is recommended; for strongly corrosive chemical materials, 316L stainless steel is necessary. Highly viscous materials prone to clumping require anti-bridging devices or customized mixing blades.

Determine equipment specifications based on production capacity requirements: Consider daily/monthly output and single-batch mixing volume to select a suitable drum volume, ensuring equipment capacity matches the production line. For small-batch production, models under 5m³ are suitable; for large-scale production, larger volume equipment of 10m³ or more is required.

Select structural functions based on the production line: For automated operation, prioritize models with pre-reserved standardized interfaces for seamless integration with automatic feeders and packaging machines; if the production line layout is limited, customize the discharge method and outlet location. For applications requiring liquid additive mixing, a spray system is necessary; dust-sensitive environments require enhanced sealing and dustproof design; and mobile models with wheels are recommended for frequent relocation.

Regarding industry standards and operating costs: The food and pharmaceutical industries require compliance with hygiene standards, prioritizing all-stainless steel construction and easy-to-clean structures; the chemical industry requires corrosion resistance, explosion-proof, and other safety requirements. While balancing cost-effectiveness, a basic carbon steel model is suitable for short-term, low-cost needs; for long-term use and special materials, a custom stainless steel model is recommended.

Dahan Machinery's Bulk Material Industrial Mixers start at $1000, but the exact price varies significantly depending on various factors. Basic carbon steel models with small capacities are affordable and suitable for mixing small to medium batches of non-corrosive materials; food-grade 304 stainless steel or chemical-grade 316L stainless steel models, due to higher requirements for corrosion resistance and hygiene, will have a higher price. When the volume increases to 10m³ or more, or when customized functions are required, such as spray systems, arch-breaking devices, or automated control systems, the cost will increase with the configuration upgrade. The price of large-capacity, highly customized industrial-grade models can be further calculated based on specific needs. Please tell us your detailed requirements and parameters, and we will provide and recommend suitable mixing equipment and models, along with a detailed quotation.

As a supplier of industrial mixers, we can provide you with customized, high-quality, and full-service Bulk Material Industrial Mixer solutions. With years of industry experience, we can customize materials including carbon steel/304/316L stainless steel, volumes from 1-50m³, and functional configurations according to your material characteristics and production capacity requirements, ensuring precise equipment adaptation to your production scenarios. Core components are sourced from well-known brands, and the entire production process undergoes strict quality control, ensuring a mixing uniformity CV ≤ 5% and a residue rate ≤ 1%, guaranteeing stable and reliable quality. We also provide pre-sales selection guidance, regular after-sales maintenance and spare parts supply services, and free technical training to help you reduce production risks and operating costs.

With its core advantages of high capacity, high precision, strong adaptability, and high safety, the Bulk Material Industrial Mixer solves the pain points of large-scale mixing of various bulk materials through customized design and efficient operation, helping enterprises improve production efficiency and ensure product quality. It is an indispensable key equipment in modern industrial large-scale production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.