Food Additive for Powder Ribbon Mixer is a homogenizing mixer designed for powdered food additives such as seasoning powder, vitamin powder, and non-dairy creamer. Its unique ribbon agitator makes it a key device for precise multi-component mixing in food processing. It can handle single batches of 50kg to 500kg, with a maximum mixing capacity of 1000kg per batch customizable to suit production scale. The device's core advantage lies in its high degree of customization. It can be configured with a 304/316L stainless steel body, a liquid spray system, a variable frequency speed control system, and customizable with enclosed structures or explosion-proof motors, adapting to diverse food additive production scenarios and providing companies with mixing solutions that meet food safety standards.

Based on our customers' production needs and environments, we offer different types and materials of Food Additive for Powder Ribbon Mixer to meet mixing requirements for various materials, such as seasoning powder, vitamin powder, and non-dairy creamer.

Horizontal Single-Shaft Ribbon Mixer: Utilizes a single-shaft driven dual-ribbon structure. The outer ribbon propels the material toward the center of the barrel, while the inner ribbon pushes it in the opposite direction, creating a circulating convection mixing process. With a single batch capacity of 500L-2000L, it's suitable for small and medium-sized feed mills producing compound feed.

Horizontal Twin-Shaft Mixer: Equipped with two parallel shafts and staggered paddles, the high-speed rotation of the paddles creates a shearing and spreading action, resulting in a 30% higher mixing efficiency than a single-shaft mixer. Capacities range from 1000L-5000L, supporting continuous operation and suitable for large-scale feed mills.

Vertical Mixer: A vertical barrel features a bottom-mounted spiral or paddle mixer. The material is lifted by the spiral and then falls back by gravity to complete mixing. Occupying only 1-2㎡, with a capacity of 50L-500L, it's economical and suitable for family farms and small breeding operations.

The Food Additive for Powder Ribbon Mixer utilizes a bidirectional ribbon design to achieve three-dimensional convection mixing, achieving a uniformity of <4% in 3-15 minutes. It also reduces energy consumption by 30% compared to traditional equipment. Its sealed structure reduces dust contamination and is compatible with stainless steel and jacketed temperature control.

High mixing efficiency: the spiral ribbon is reasonably designed, which can quickly and efficiently mix the additive powder evenly, shorten the production cycle and improve production efficiency.

High mixing uniformity: mixing uniformity is an important guarantee for food safety and quality. The spiral ribbon mixer can effectively eliminate the dead corners generated during the mixing process and ensure the uniformity and consistency of the additive powder mixing.

Simple and convenient operation: The equipment has a simple structure, is easy to operate and maintain, and can reduce the workload of operators.

Meet food safety standards: The material, process, and design all meet food safety standards to ensure the cleanliness and hygiene of the production process and guarantee food quality.

Strong scalability: Mixers of different sizes and configurations can be customized according to actual production needs to meet the production needs of different specifications.

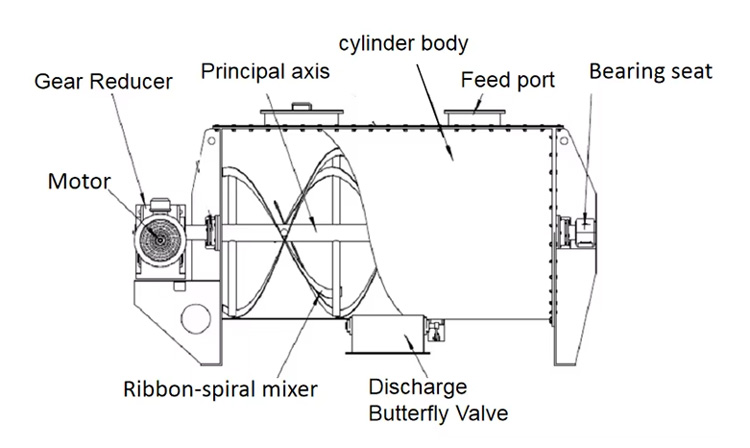

The Food Additive for Powder Ribbon Mixer consists of five core components, ensuring high-speed mixing that meets food standards. The interior is polished to eliminate dead corners; the core mixing element is a double-layered ribbon, with the outer layer gathering the material and the inner layer dispersing it. A variable frequency reduction motor provides stable power. The inlet is equipped with a dust cover, and the outlet is equipped with a quick-opening valve to control material flow in and out.

Mixing chamber: a mixing chamber used to hold food additive powder, usually with suitable capacity and structure to ensure effective mixing operation.

Spiral agitator: a core component of the mixer, which effectively mixes food additive powder through rotational motion to ensure uniform mixing effect.

Motor and transmission device: a motor and transmission device driving the spiral agitator, providing power support so that the spiral agitator can rotate and perform mixing operations.

Control system: a control system used to set mixing time, speed and other related parameters to ensure precise control of the mixing process.

Discharge port: used to take out the mixed food additive powder to facilitate subsequent production processes or packaging operations.

The working principle of food additive for powder ribbon mixer is similar to that of pharmaceutical raw material powder ribbon mixer. Both are based on the rotating motion of the spiral ribbon to tumble and stir the powder material to achieve uniform mixing.

Movement of the spiral ribbon: When the spiral ribbon rotates, the outer spiral ribbon pushes the material upward, and the inner spiral ribbon brings the material downward to form a circular flow.

Tumbling of materials: During the circular flow, the material tumbles continuously, and different components contact each other to promote mixing.

Mixing uniformity: The design and rotation direction of the spiral ribbon can effectively overcome the static electricity and adhesion of the powder and ensure the uniformity of mixing.

The Food Additive for Powder Ribbon Mixer is suitable for mixing a variety of powders with food additives. Common powders include flour, starch, protein powder, and traditional Chinese medicine powder. Food additives include sweeteners, preservatives, colorants, and nutritional supplements.

Vitamin Premix: Utilizing a low-shear reverse-ribbon design, the mixing uniformity is ≤5% CV, minimizing the loss of heat-sensitive ingredients.

Flavors and Fragrances: The atomizing spray system ensures uniform encapsulation of liquid flavors and carriers, achieving an aroma retention rate of ≥95%. Precisely proportioning compound seasonings and trace ingredients is achieved with an error of ≤0.5%.

Thickener: The shear force of the double-ribbon design breaks down colloid agglomerates, improving viscosity consistency by 50% after mixing.

Leaving Agent: A temperature-controlled jacket is used to maintain the mixing temperature at ≤40°C, preventing premature reactions that affect the leavening effect.

Probiotic Powder: Utilizing an inert gas-protected mixing process, the viable bacterial survival rate is ≥97%, surpassing the 10% loss rate of traditional processes.

Dietary Fiber: The modular design allows for simultaneous addition of liquids, increasing solubility by 30% after mixing.

The Food Additive for Powder Ribbon Mixer can be used to mix seasoning powders, add and mix vitamin/mineral powders, formulate non-dairy creamer and meal replacement powders, and homogenize baking mixes and solid beverage powders, meeting the mixing needs of food additive manufacturers and food processing companies.

Seasoning production: Mix various spices, spices, seasoning powders, etc. to prepare various seasonings.

Baked food production: Mix flour, sugar, yeast, additives, etc. to prepare baked foods such as cakes and bread.

Beverage production: Mix various powdered additives, such as milk powder, powdered sugar, essence, etc. to prepare various beverages.

Meat product processing: Mix various additives, such as marinade, pigments, preservatives, etc. to process meat products.

Other food production: Mix various additives, such as thickeners, emulsifiers, stabilizers, etc., for the production of various foods.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

When selecting a Food Additive for Powder Ribbon Mixer, first determine the capacity based on your production scale. Furthermore, consider the additive's characteristics and choose a food-grade stainless steel material with a chamber that is free of dead corners to ensure compliance, uniform mixing, and minimize contamination.

Laboratory Series: Suitable for new product development, formulation testing, and small-batch trial production. Made of 304 stainless steel, with a manual quick-opening door.

600-1200L Pilot Series: Suitable for process validation and pilot production, with a mixing cycle of 8-15 minutes and a residual content of <0.1%.

1800-6000L Standard Production Line: With a processing capacity of 4000-6000 kg/hour and a motor power of 7.5-55 kW, it is suitable for large-scale industrial manufacturers.

The Food Additive for Powder Ribbon Mixer, used in the food additive industry, must strictly adhere to industry-specific requirements. First, it must be made of food-grade stainless steel to prevent additive contamination. Second, the mixing chamber must be designed with no dead corners to ensure uniform mixing and no residue.

Material: The part in contact with the material must be made of food-grade stainless steel, commonly SUS304 or SUS316L, to meet food hygiene requirements and prevent material contamination.

Sealing: The shaft end seal and the discharge port seal must be good to prevent dust leakage from causing environmental pollution and material loss.

Cleanliness: The design should be easy to clean, minimize dead corners, facilitate thorough cleaning and production change, and prevent cross contamination.

No residual discharge: The design of the discharge valve should ensure that the material is emptied as much as possible and reduce residue.

Dahan Machinery Manufacturing Co., Ltd. is deeply involved in the field of food additive mixing. Aiming at the characteristics of preservatives, nutritional enhancers, probiotic powder and other materials, the core products are made of 316L stainless steel, equipped with temperature control jacket (±1℃), silicon nitride ceramic wear-resistant spiral belt and inert gas protection system to meet the mixing needs of heat-sensitive and highly corrosive additives. We have provided customized solutions and 24-hour response services to more than 300 food companies around the world, enabling the safe production of food additives with the dual drive of technology and service.

We set the industry benchmark with superior quality, high-speed service to ensure on-time delivery, flexible solutions to meet diverse needs, and a professional team to provide full support.

Customization Capabilities: We can precisely customize your equipment, from materials to structure, based on your material characteristics, such as powders, granules, corrosiveness, and operating conditions, conveying height, angle, and output, for greater adaptability.

Quality Assurance: We use high-strength carbon steel plates and food-grade/industrial-grade stainless steel. Key components undergo rigorous testing to ensure long-term stable operation.

Service Support: We provide a full-process service from initial selection consultation, mid-term installation guidance, to ongoing maintenance. We respond quickly to after-sales needs and reduce your production concerns.

The Food Additive for Powder Ribbon Mixer utilizes counter-rotating double or multi-layer ribbons to achieve convection, shear, and diffusion within the mixing chamber, quickly achieving uniform mixing. It is particularly well-suited for mixing fine powders such as food additives, chemical powders, and pharmaceutical raw materials. The device supports customizable mixing methods, making it a key component in powder production to ensure mixing quality and improve processing efficiency. It provides stable and reliable powder mixing solutions for businesses of all sizes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.