High-Performance Powder Ribbon Mixer is a core piece of equipment developed to meet the mixing needs of various powder materials. With its precise mixing structure and flexible customization design, the equipment employs a horizontal double-ribbon mixing system. The outer and inner ribbons rotate in opposite directions to create forced convection, which can quickly break up powder agglomerates and achieve uniform mixing. A single mixing cycle takes only 3-10 minutes, with a mixing uniformity consistently above 99%. It supports comprehensive non-standard customization, and is available in carbon steel and 304/316L stainless steel. The mixing capacity ranges from 50L to 5000L, adapting to different production capacity requirements from small-scale pilot production to large-scale mass production. Furthermore, it can be equipped with features such as a liquid spraying device, dust removal system, and roller design to address specific process challenges, creating powder mixing solutions tailored to the actual production needs of enterprises.

The High-Performance Powder Ribbon Mixer, with its low energy consumption, low residue, high loading coefficient, and modular design, is suitable for the needs of various industries such as food, chemical, and building materials, and has become a key piece of equipment for improving efficiency and quality in mass production.

Ultra-Uniform Mixing:The ribbon design allows powder to tumble and convection throughout the drum, ensuring rapid and uniform mixing of powders of different compositions and particle sizes, resulting in more stable product quality.

Extremely Minimal Residue: The optimized structure ensures clean mixing. After mixing, minimal powder residue is left inside, reducing material waste and simplifying cleaning.

Low Energy Consumption: Low electricity consumption during operation saves businesses significant electricity costs, resulting in a clear cost advantage in the long run.

Flexible Material Selection: We can select different materials to meet the mixing standards of customers in various industries, offering options such as stainless steel and carbon steel.

Fast Mixing Speed:Fast mixing speed, with a single mixing cycle of only 3-10 minutes, maintaining a mixing uniformity of over 99%.

Wide Applicability:Suitable for mixing various powder materials, meeting the powder mixing needs of different industries.

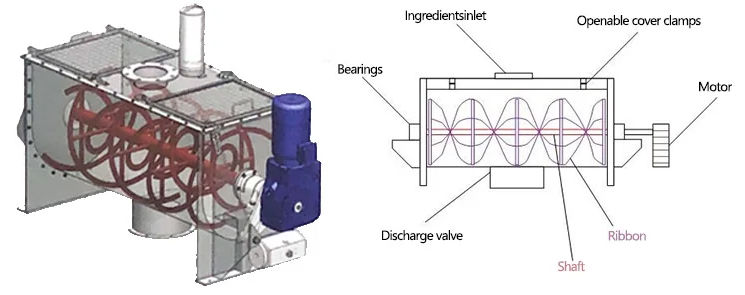

The High-Performance Powder Ribbon Mixer uses a U-shaped cavity as the material mixing carrier, and its core technology achieves efficient homogenization through a dual-ribbon mixing system. A motor-driven reducer rotates the mixing shaft, while the outer ribbon pushes the powder material towards the center of the cavity along the inner wall, and the inner ribbon transports the material from the center to both sides in the opposite direction, forming a strong forced convection circulation. During this process, the powder is continuously sheared, tumbled, and mixed, quickly breaking up clumps and ensuring thorough blending of different powder components. The entire mixing process is thorough, achieving uniform mixing within 3-10 minutes, and the final product is discharged through the bottom outlet.

The High-Performance Powder Ribbon Mixer features a built-in double-layer counter-rotating helical ribbon blade. The outer layer centrifugally gathers the material, while the inner layer centrifugally conveys it, creating a convective vortex. This, combined with a cycloidal reducer direct drive, achieves low-power, high-efficiency mixing. The equipment employs a pneumatic, large-opening unloading design, resulting in a residue rate as low as 0.1%.

Cylinder: Usually cylindrical or trough-shaped, it is the main container of the mixer and is used to hold the powder materials to be mixed.

Ribbon agitator: This is the core component of the mixer, consisting of two or more layers of inner and outer ribbons. The ribbon usually adopts a wide blade design, which can generate strong stirring and conveying force when rotating.

Discharge device: Located at the bottom or side of the cylinder, it is used to discharge the mixed powder materials.

Feeding device: Used to add various powder materials into the mixer cylinder.

Sealing device: In order to prevent the leakage of powder materials and external impurities from entering the mixer, sealing devices are provided at various connection parts of the cylinder and the connection between the shaft of the ribbon agitator and the cylinder.

Control system: Used to control the operating parameters of the mixer, such as stirring speed, stirring time, feed amount, discharge amount, etc.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

With its unique double-ribbon structure and efficient transmission design, the High-Performance Powder Ribbon Mixer can achieve comprehensive mixing of everything from dry powders to high-moisture pastes.

Low-moisture powders (moisture content ≤ 5%): such as cement powder, flour, and dry chemical powders. The forced convection of the double-ribbon structure ensures rapid homogenization without clumping.

Medium-moisture powders (moisture content 5%-15%): such as starch, protein powder, and some feed ingredients. A spray device can be added for precise moisture control, preventing clumping and ensuring uniform mixing.

High-moisture powders (moisture content 15%-25%, loose): such as certain food filling powders and organic fertilizer powders. A wear-resistant ribbon and an anti-stick cavity are required to ensure smooth mixing without residue.

Belt mixers use spiral ribbon blades as their core to achieve mixing of high-viscosity materials through omnidirectional flow in the axial, circumferential, and radial directions. Paddle mixers, on the other hand, are characterized by straight or folded blades and complete the circulation of low-viscosity fluids through tangential and radial flow. They are commonly used in fields such as coatings, water treatment, and food.

| Comparison Items | Ribbon Mixer | Paddle Mixer |

| Structural Features | Composed of a horizontal cylindrical container and ribbon - shaped spiral blades installed inside the container. | The blades are simple in shape, usually flat rectangular or trapezoidal, and are connected to the agitator shaft by welding or bolts. |

| Working Principle | During operation, the material moves axially from one end of the mixer to the other under the push of the ribbon, and at the same time, it moves radially in the gap between the ribbon and the container wall, forming a complex three - dimensional flow pattern to achieve full mixing of the material. | When the blades of the paddle mixer rotate, they mainly shear and push the material, forming a flowing material flow that drives the surrounding materials to move together, thus realizing the mixing of materials. |

| Application Scenarios | Suitable for mixing high - viscosity and large - volume materials, such as in industries like plastics, rubber, food, and pharmaceuticals. | Suitable for mixing low - viscosity materials, such as in the processes of liquid material mixing, dissolution, and heat transfer. |

| Mixing Effect | Due to its unique spiral structure and three - dimensional flow pattern, it can achieve a high degree of uniform mixing of materials, with high mixing accuracy. It can mix materials in different proportions very evenly, especially for some difficult - to - mix materials. | The mixing effect is relatively weak, mainly suitable for occasions where the requirement for mixing uniformity is not particularly high. |

The High-Performance Powder Ribbon Mixer, with its high-speed, uniform mixing, low residue, and strong adaptability, has become a core piece of process equipment. We can provide suitable mixing equipment for different customers, ensuring that every production line operates normally.

Pharmaceutical industry: It is necessary to mix a variety of pharmaceutical excipients (such as lactose, microcrystalline cellulose, etc.), requiring a mixing uniformity of ≥99% and complying with GMP clean standards. 316L stainless steel ribbon mixer is selected, equipped with a dustproof sealing system and CIP cleaning function.

New energy materials: Lithium battery material manufacturers need to evenly mix nano-scale lithium cobalt oxide and conductive agents to avoid stratification and agglomeration. Customized gas-protected ribbon mixer, oxygen content controlled <50ppm.

Food additives: The company needs to evenly disperse 0.5% flavor into the carrier powder, using a three-stage dynamic mixing system: main ribbon coarse mixing + auxiliary paddle fine mixing + pneumatic spray system.

The price of a High-Performance Powder Ribbon Mixer varies depending on the equipment configuration, starting at $1200 for the basic model. The price is affected by factors such as mixing capacity, material selection, and customized functions. For example, the small basic model (50-300L, carbon steel, no additional functions) offers excellent value and is suitable for small-batch pilot production or simple powder mixing scenarios. Medium and large models (500-5000L), stainless steel models, or customized models with added functions such as liquid spraying, dust removal, and variable frequency speed control will have higher prices due to increased material costs and process complexity. Overall pricing balances performance and economy; the most suitable and cost-effective equipment solution can be selected based on actual production capacity, material characteristics, and process requirements.

As a professional manufacturer of High-Performance Powder Ribbon Mixers, Dahan Machinery has been deeply involved in the research and development and production of mixing equipment for over ten years. We have an independent R&D center and a standardized production workshop, equipped with advanced CNC machining equipment and precision testing instruments, ensuring that every piece of equipment meets international quality standards. Our products cover a variety of specifications of ribbon mixers, featuring high-speed mixing, low energy consumption, and easy maintenance, and are widely used in chemical, pharmaceutical, food, new materials, and other industries. We provide a full range of services from solution design and customized production to installation, commissioning, and after-sales maintenance, and have a professional technical team and a rapid response mechanism to create a worry-free and reliable cooperation experience for our customers.

The High-Performance Powder Ribbon Mixer, with its unique ribbon structure and advanced design concept, achieves high-speed and uniform mixing of powder materials, effectively solving the pain points of uneven mixing and excessive residue in traditional equipment. It is widely applicable to various industries such as chemical, pharmaceutical, and food, helping companies improve product quality and production efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.