Vertical Powder Ribbon Mixer for Solids and Powders features a vertical design, effectively saving workshop space. The mixing system, centered on a belt structure, uses a rotating belt to tumble and shear the material, achieving uniform mixing of solid particles and powders. It is suitable for materials ranging from fine powders to small to medium-sized particles. Available in carbon steel and stainless steel, it can be equipped with rollers, greatly enhancing its mobility and allowing for flexible deployment across different production areas. Customization is also available to meet specific customer needs, including mixing capacity, mixing speed, feeding method, and the addition of features such as spraying and heating. It comprehensively matches the mixing processes of various industries, providing customized solid-powder mixing solutions for businesses.

The Vertical Powder Ribbon Mixer for Solids and Powders offers advantages such as precise adaptation to solid and powder mixing scenarios. Its compact vertical structure saves space, and it can be equipped with casters for flexible movement. The belt mixing component achieves efficient material mixing through forced convection, with a uniformity of over 99%. It is suitable for various material forms, meeting both general industrial and food/pharmaceutical compliance requirements, helping multiple industries improve mixing efficiency and product stability.

Uniform Mixing Adaptability to Various Material Forms:Utilizing a belt mixing structure, the rotating belt propels solid particles and powders to tumble and shear, quickly breaking up material agglomerates and achieving a mixing uniformity of over 99%. It can handle both fine powder mixing and powder compounding with small to medium-sized solid particles.

Material Options:Available in carbon steel and 304/316L stainless steel, suitable for general industrial scenarios and high-hygiene-requirement fields such as food and pharmaceuticals, balancing cost-effectiveness and compliance.

Flexible Customization: Mixing capacity (50L-3000L), mixing speed, and feeding method can be customized according to customer needs. Features such as spraying and heating can also be added to match different process requirements.

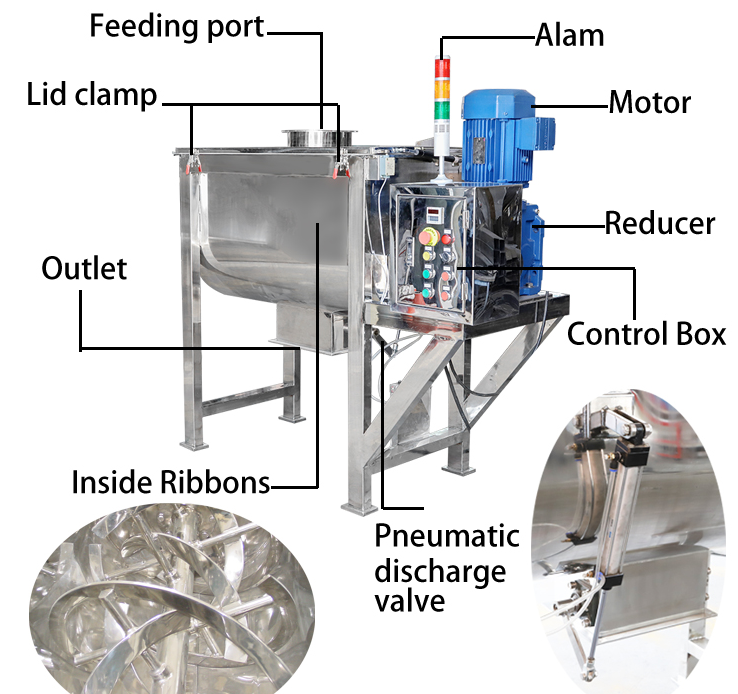

The Vertical Powder Ribbon Mixer for Solids and Powders is designed for efficient mixing of solids and powders. Its core consists of five main components, ensuring precise mixing, easy operation, and adaptability to various scenarios.

Mixing Cylinder: Available in carbon steel or 304/316L stainless steel to meet the corrosion resistance and hygiene requirements of different industries. The inner wall of the cylinder is polished to reduce material residue. The volume is customizable, and a sealed top cover prevents dust spillage during mixing.

Agitation System: The core is a belt agitator, consisting of an agitator shaft and a mixing belt. The agitator belt uses a spiral or paddle design, rotating to tumble and shear the material, achieving uniform mixing of solids and powders.

Transmission System: Composed of a motor, reducer, and coupling, providing stable power to the mixing system. The motor power can be matched to the equipment capacity. The reducer lowers the speed and increases the torque, ensuring smooth operation of the mixing belt.

Feed Inlet: Located at the top of the cylinder, it can be connected to a feeder or manually fed. Some models can be equipped with a screening device to remove impurities. Discharge port: Located in the conical area at the bottom of the cylinder, equipped with a pneumatic or manual valve to precisely control the discharge speed and flow rate, preventing material caking and blockage.

Support structure: A frame is installed at the bottom, with the option to add casters for easy movement and repositioning, improving workshop layout flexibility.

Vertical powder ribbon mixer for solids and powders drives solid and powder materials to tumble, shear and mix continuously in the mixing barrel through the rotation of the spiral agitator. This design ensures that the materials are fully mixed, avoids dead corners, and achieves a uniform mixing effect. The unique structure of the spiral agitator can effectively push the materials to the center of the mixing barrel, thereby achieving all-round mixing.

Vertical Powder Ribbon Mixer for Solids and Powders Technical Specifications

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The Vertical Powder Ribbon Mixer for Solids and Powders, with its adaptability to both solid and powder materials and its customization capabilities, is widely used in mixing scenarios across multiple industries.

Food Processing Industry: Suitable for homogeneous mixing of food ingredients, such as blending flour and grain powders, mixing milk powder and vitamin powders, and stirring seasonings and fillers. It can also be used for mixing ingredients in functional foods such as candy powders and meal replacement powders.

Chemical and Building Materials Industry: Suitable for mixing chemical powders and solid additives, such as mixing paint powders and curing agents, plastic granules and modifiers, and rubber additives and fillers. In the building materials field, it can mix cement and additives, dry mortar and aggregates. The carbon steel version is suitable for industrial-grade corrosion resistance requirements.

Pharmaceutical and Health Products Industry: Meets the precise mixing requirements of pharmaceutical powders and excipients, such as stirring traditional Chinese medicine powders and excipients, and mixing health product ingredients and nutritional additives. It offers high mixing uniformity, ensuring the stability of the ingredients in pharmaceuticals and health products.

Feed production industry: Suitable for mixing raw materials for livestock and poultry feed, such as basic raw materials like corn flour and soybean meal powder, and mixing with mineral and vitamin premixes. Large-capacity models can be customized, and the roller design facilitates workshop movement, meeting the batch production needs of different feed formulations.

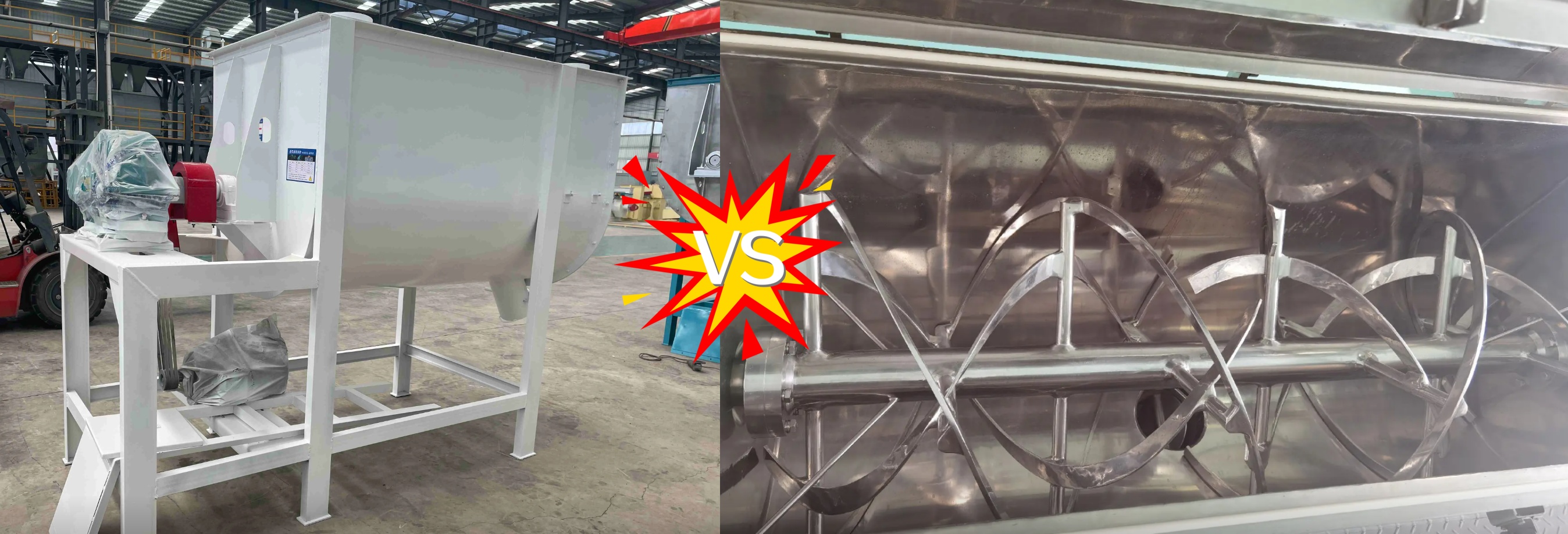

The core difference between vertical mixers and belt mixers lies in their structural form and mixing principle, which in turn affects mixing efficiency, suitable materials, and application scenarios. Their specific applications differ significantly.

Structural Differences: Belt mixers are mostly horizontal in structure, with a core belt-shaped mixing component. This component rotates, shears, and pushes materials, creating forced convection mixing, resulting in more vigorous material circulation and mixing within the chamber.

Suitable Materials: Vertical mixers are suitable for small to medium batches of free-flowing powders and granules, but struggle with high-viscosity or large solids. Belt mixers are suitable for mixing solids and powders, materials with a small amount of viscosity, and scenarios requiring high-intensity mixing, offering superior dispersing effect on agglomerated materials.

Mixing Efficiency: Vertical mixers have a longer mixing cycle (10-20 minutes/batch); belt mixers mix faster (5-15 minutes/batch) with higher uniformity, making them particularly suitable for dispersing trace components.

Space and Mobility: Vertical mixers have a vertical layout, saving space and can be moved by adding casters; belt mixers have a large footprint and poor mobility, while both vertical and belt mixers offer space advantages.

Application Scenarios: Vertical mixers are mostly used for small-batch production in the food and feed industries; belt mixers are widely used in chemical, building materials, and large-scale food processing, suitable for batch production needs.

The Vertical Powder Ribbon Mixer for Solids and Powders can be equipped with a variety of additional functions to further expand its adaptability and improve mixing quality. Core additional functions are designed around pressure control, temperature regulation, and ease of operation, precisely matching the process requirements of different industries.

Pressure/Vacuum System: By adding a pressure/vacuum control device to the sealed structure of the mixing cylinder, the internal pressure environment of the mixer can be adjusted. Under vacuum conditions, contact between materials and air is prevented, avoiding the deterioration of easily oxidized or moisture-absorbing solids or powders, while also reducing dust emissions.

Heating/Cooling Jacket: A jacket structure is added to the outside of the mixing cylinder, allowing heating via steam or heat transfer oil, or cooling via cooling water. The heating function assists in material drying and promotes component blending, suitable for powder processing requiring temperature-controlled mixing; the cooling function controls the temperature rise of materials during mixing, protecting heat-sensitive components from degradation.

Automated Control Module: Equipped with a PLC control system and touchscreen, allowing precise setting of stirring speed, mixing time, and pressure/temperature parameters for automated operation and data recording. Combined with weighing sensors, it enables accurate material feeding and batch metering, facilitating production traceability.

Liquid Spraying Device: Precisely sprays liquid additives, achieving uniform mixing of solid powder and liquid, suitable for processes requiring liquid components.

Filtration and Dust Removal Device: A top-mounted dust collector collects dust generated during mixing, ensuring a clean workshop environment and reducing material waste through recycling.

Moving Casters and Locking Device: Locking casters are installed at the bottom of the frame for easy movement and position adjustment, ensuring stable operation when fixed.

As a leading manufacturer specializing in solid and powder mixing, we have focused on the research and development and production of Vertical Powder Ribbon Mixers for Solids and Powders for many years. Our equipment features an innovative vertical structure and a high-efficiency belt mixing system, precisely adaptable to the mixing needs of materials with different specific gravities and particle sizes, achieving a uniformity of over 99%. We support full-process customization services, from material selection (carbon steel/stainless steel), cylinder dimensions to functional modules (such as heating, vacuum, and spraying devices), all can be designed to your needs. As a source factory, we strictly control quality and provide one-stop solutions to help customers reduce costs and increase efficiency.

How long does it take to mix solids and powders with the Vertical Powder Ribbon Mixer?

Generally, it takes 5-20 minutes per batch. For fine powders with good flowability (such as flour and chemical powders), 5-10 minutes is sufficient to achieve uniform mixing. For materials containing lumpy solid particles or sticky materials (such as powders with additives), it takes 10-20 minutes. Using a variable frequency speed control can optimize the mixing rhythm.

What types of materials can the Vertical Powder Ribbon Mixer for Solids and Powders mix?

It primarily mixes fine powders, small to medium-sized solid particles, and composite systems of both. Powders include flour, milk powder, chemical powders, and traditional Chinese medicine powders; solids include plastic granules, feed aggregates, building material granules, and food grains. It is also suitable for materials with a small amount of viscosity (such as powders with added syrup or plastic granules containing additives), as well as mixtures requiring the addition of trace amounts of ingredients (such as vitamin powder mixed with base powders).

What factors should be considered when choosing a Vertical Powder Ribbon Mixer for Solids and Powders?

When selecting a vertical powder belt mixer suitable for solids and powders, key considerations include: material characteristics (matching solid particle size, powder flowability, and presence of sticky components); material compatibility (selecting carbon steel or stainless steel based on industry); capacity requirements (determining the equipment capacity corresponding to the single mixing volume and daily output); and customized functions (whether rollers, spraying, or heating devices are needed).

Address:China,Yanjin county forest park gate to the west 1000 meters north road.