Paint Powder Ribbon Mixer is a product used for mixing powders and liquids in the paint production process. Its unique ribbon structure design can achieve uniform mixing of paint powders within 1-15 minutes. Our factory's paint powder ribbon mixers support non-standard customization, are equipped with explosion-proof motors, and can be adjusted in height, inlet/outlet position, and shape according to customer's actual needs, thus achieving perfect integration with the production site. To meet the needs of different production environments, the paint powder ribbon mixer is available in both carbon steel and stainless steel, ensuring good corrosion resistance and service life. Additionally, a roller design can be added as needed for easy movement and installation, providing customers with more flexible solutions.

The Paint Powder Ribbon Mixer leverages its advantages to address industry pain points such as high powder fineness, easy agglomeration, and strict requirements for precise proportioning. Customization allows it to adapt to various mixing scenarios.

High Mixing Uniformity: The equipment employs a double-layer concentric reverse ribbon structure. This design allows for thorough shearing and mixing of paint powder within the drum, ensuring uniform dispersion even for trace amounts of additives with proportion differences as small as 1‰.

Strong Adaptability: It can handle both common powder coating substrates and fillers, as well as viscous paste-like coatings and heat-sensitive paint powders. A spray system can also be added for solid-liquid mixing.

Low Residue and Anti-Pollution: The inner wall of the drum is made of polished 304/316L stainless steel. The ribbon can be equipped with a PTFE anti-stick coating, significantly reducing material adhesion. Combined with a pneumatic large-opening unloading structure, unloading speed is fast and the residue rate is less than 0.5%.

Customization Support: Capable of meeting the specific process requirements of paint production; the jacketed cylinder allows for heating/cooling, suitable for mixing heat-sensitive paint powders; it can integrate an online monitoring system to provide real-time feedback on parameters such as temperature, humidity, and uniformity during the mixing process; it can also be linked with drying and sieving equipment to form an integrated production unit.

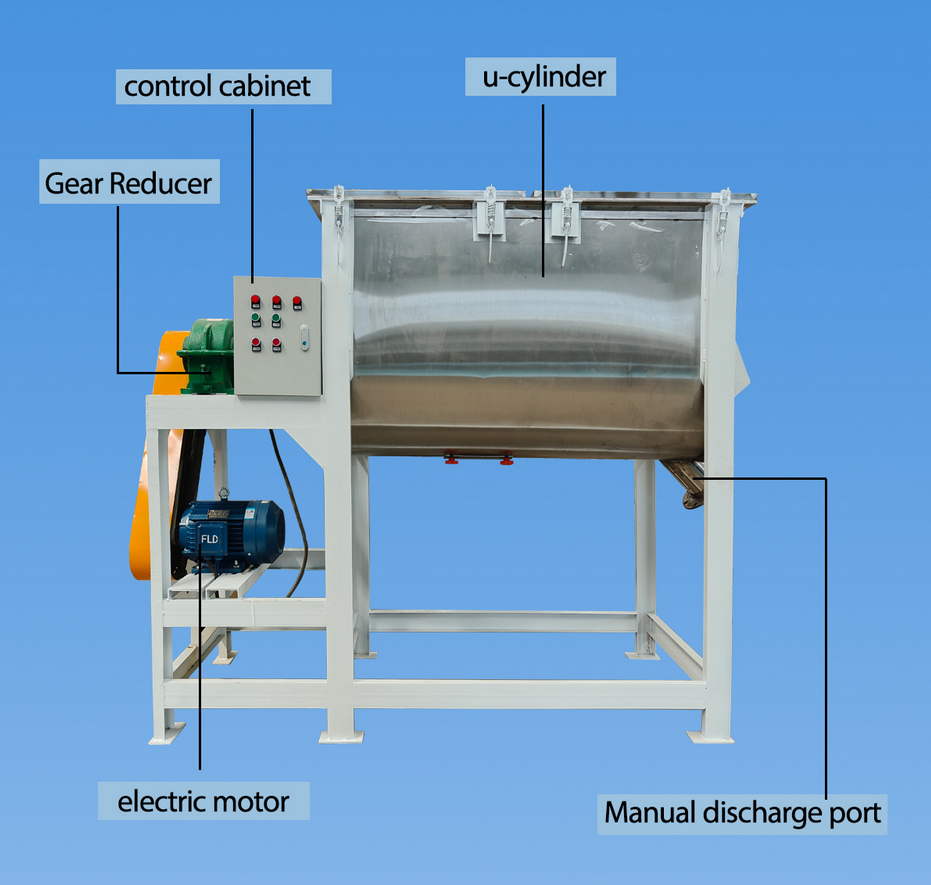

The Paint Powder Ribbon Mixer mainly consists of a horizontal U-shaped cylinder, a concentric counter-rotating spiral ribbon agitator, a transmission system, a discharge mechanism, and auxiliary functional components. The U-shaped cylinder is mostly made of polished stainless steel with a smooth, non-stick inner wall; the inner and outer spiral ribbons of the agitator are coaxially installed, with the outer ribbon pushing the material on the cylinder wall towards the center, and the inner ribbon pushing the material at the center towards both ends, forming a three-dimensional convection mixing; the transmission system consists of a motor and a reducer, providing stable power for mixing; the discharge port adopts a pneumatically designed large opening for low-residue, rapid discharge; auxiliary components can be selected according to process requirements, such as a jacketed temperature control system, a liquid spray system, and a sealing dust removal device, to meet diverse needs for paint powder mixing.

A Paint Powder Ribbon Mixer uses a ribbon mixer, typically consisting of a horizontal cylinder, multiple spiral ribbons, and a drive system. The ribbon is the core component of the machine; its rotation generates strong axial and radial motion, causing the paint powder to continuously collide, rub, and compress, thus achieving uniform mixing.

Paint Powder Ribbon Mixers offer a variety of capacity options to meet different production needs, ensuring adaptability to production lines of varying sizes. We provide customization services, able to tailor the equipment capacity to your specific requirements.

100-1000kg: Suitable for small production lines or laboratory testing, capable of meeting the mixing needs of small batches of paint.

1200-1800kg: Suitable for medium-sized production lines, capable of handling larger batches of paint mixing tasks, commonly used in medium-sized paint factories or other industries with medium-scale production needs.

1600-2400kg: Suitable for medium to large-sized production lines, capable of handling even larger-scale paint mixing. This model is commonly found in large-scale manufacturing enterprises, flexibly handling high-volume production needs.

2400-3600kg: Suitable for large-scale production, offering higher throughput capacity, applicable to large-scale batch production in the coatings and other industries, ensuring stable operation under high load conditions.

3200-4800kg: Suitable for ultra-large-scale factory production lines, capable of handling large-volume paint powder mixing needs, widely used in large paint factories and enterprises requiring continuous high-volume production.

The Paint Powder Ribbon Mixer is widely used for mixing various types of paints, especially suitable for mixing powder coatings, liquid coatings, and viscous coatings. Its unique ribbon structure ensures thorough mixing of various raw materials.

Water-based coatings: Suitable for dispersing and mixing emulsions, pigments, and additives, solving problems such as emulsion demulsification and pigment sedimentation, and improving coating gloss and stability.

Oil-based coatings: Achieve uniform mixing of resins, pigments, talc, and other fillers, enhancing coating density and weather resistance.

Powder coatings: Support the pre-mixing process of thermosetting powders, ensuring uniform dispersion of the curing agent and substrate, and guaranteeing coating hiding power.

Functional coatings: Meets the requirements for stable mixing of microcapsule powders such as flame retardants and antibacterial agents, ensuring uniform distribution of functional components.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

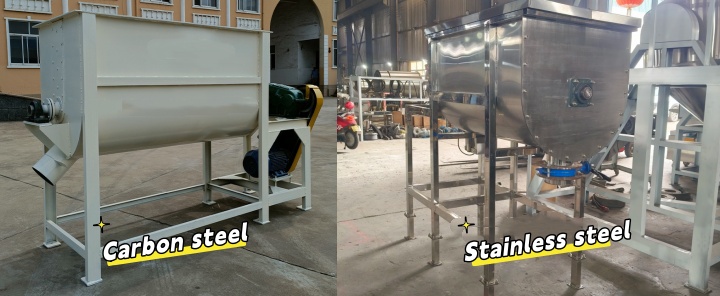

When choosing a Paint Powder Ribbon Mixer, the choice of material is crucial. Generally, paint powder mixers can be made of either carbon steel or stainless steel. For conventional non-corrosive paint powders, carbon steel is sufficient and more economical. For paints containing corrosive ingredients or requiring high hygiene standards, stainless steel is recommended. It not only offers excellent corrosion and wear resistance but also ensures the stability and hygiene of the equipment during long-term use.

Yes, we support non-standard customization. The core of the system is a precision atomization spray system integrated above the cylinder. This system consists of a storage tank, metering pump, atomizing nozzles, and a control system. During operation, the metering pump precisely controls the spray volume according to the paint formula. The atomizing nozzles break down liquids such as water or resin emulsions into micron-sized droplets, evenly spraying them onto the high-speed tumbling paint powder. Combined with the three-dimensional convection mixing motion of the ribbon, the liquid quickly penetrates and coats the powder particles, avoiding the localized clumping and uneven mixing problems caused by traditional direct dripping.

Our company, a manufacturer of architectural exterior powder coatings, previously faced problems with uneven mixing of metallic pigments, resins, and fillers using traditional mixing equipment. This resulted in inconsistent coating color and gloss, as well as poor dispersion of trace functional additives, leading to a high rate of customer complaints. We introduced a customized Paint Powder Ribbon Mixer for them. The equipment features a three-layer concentric reverse spiral ribbon structure and a precision atomization water spray system. The outer spiral ribbon pushes the material from the cylinder wall towards the center, while the inner spiral ribbon disperses the material in the center. The water spray system atomizes and evenly sprays water-based additives, preventing localized clumping. After implementation, the mixing uniformity improved to 99.5%, fully meeting the requirements of various construction projects.

Dahan Machinery, as a professional Paint Powder Ribbon Mixer manufacturer, is committed to providing customers with high-quality, high-performance mixing equipment to meet the production needs of different industries. With years of industry experience and technological accumulation, our company adheres to a rigorous quality management system, strictly controlling every step from design and manufacturing to after-sales service to ensure the stability and reliability of our equipment. We not only provide standardized paint powder ribbon mixers but also support non-standard customization. We can tailor suitable equipment specifications, functional configurations, and design details according to the customer's actual production environment and needs. Whether it's the equipment height, the shape and position of the inlet and outlet, or special functions such as roller design, we can flexibly adjust them according to customer requirements to ensure perfect integration of the equipment with the production line.

Our Paint Powder Ribbon Mixer overcomes the industry pain points of paint powder mixing with its core advantages of high uniformity, strong adaptability, and low residue. Its expandable spray and temperature control functions can meet the production needs of multiple types of paints.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.