Polymer powder paddle mixer is a special equipment, a mechanical equipment used to evenly mix various polymer powders. Through the internally designed paddles, the polymer powder is effectively stirred and mixed by the rotating motion of the paddles. This mixer can ensure that the powder particles are fully turned and mixed during the mixing process, avoiding the occurrence of lumps or uneven mixing, thereby improving production efficiency and product quality.

Polymer powder for paddle mixer is widely used in chemical, plastic, rubber, coating and other industries, and is suitable for the mixing needs of various polymer powders, such as polyethylene, polypropylene, polyvinyl chloride, etc. This equipment is easy to operate, can maintain the quality of the mixed materials, and improve production efficiency. It is one of the important mixing equipment in the production process.

Structural composition

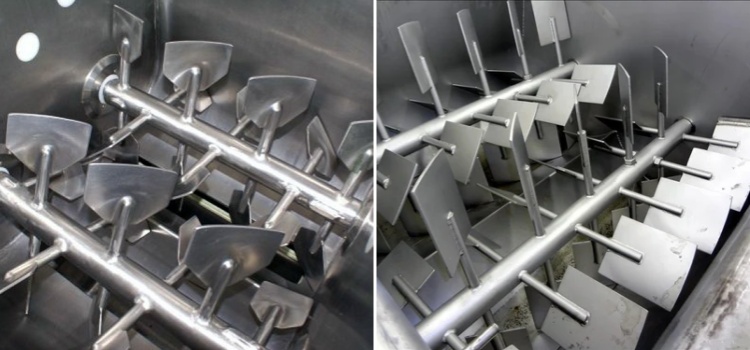

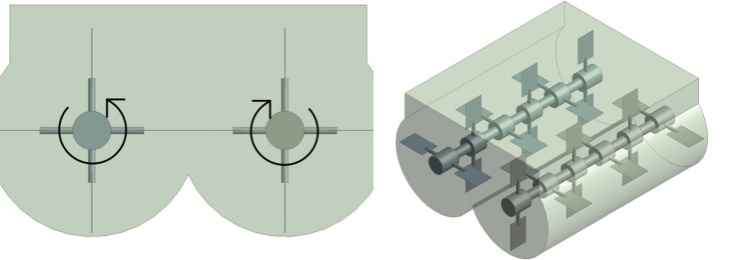

Paddle: The mixer is equipped with paddles, usually multiple paddles, arranged in a spiral shape.

Casing: The outer shell of the mixer, the internal space is used to accommodate powder and paddles for mixing.

Transmission: A device that drives the paddles to rotate, usually a motor or other power source.

Working principle

Loading: Put the polymer powder to be mixed into the casing of the mixer.

Start the equipment: Start the transmission device and drive the paddle to start rotating.

Stirring and mixing: The rotating motion of the paddle makes the powder constantly flipped and stirred, so that the powder particles are mixed with each other.

Even mixing: Through the design and movement of the paddle, ensure that the powder is fully mixed inside the mixer to avoid lumps or uneven mixing.

Control parameters: The operator can control the speed, mixing time and other parameters of the mixer to meet different mixing requirements.

Polymer powder paddle mixers with different processing capacity have many differences in structure, performance, and applicable scenarios. The following is a detailed introduction for you.

Small processing capacity (50-200 kg per hour): The volume of the mixing tank is usually 100-500 liters, and most of them adopt a cylindrical design, which occupies a small area and is easy to place in a laboratory or a small workshop. The mixing cycle is relatively short, and a batch of mixing can generally be completed within 10-20 minutes.

Medium processing capacity (200-1000 kg per hour): The volume of the mixing tank is 500-2000 liters, the drive motor power is increased to 3-15 kilowatts, and the mixing time for each batch is about 15-30 minutes. The coefficient of variation of mixing uniformity can be stabilized at about 3%, which can ensure the high consistency of product quality.

Large processing capacity (more than 1000 kg per hour): The mixing tank volume is more than 2000 liters, which meets the mixing needs of a large number of materials, and the power is usually more than 15 kilowatts.

The mixer polymer powder paddle mixer adopts a double-layer staggered paddle design and is made of 304/316L stainless steel. Its advantages are as follows.

Even mixing: Polymer powder for paddle mixer can ensure even mixing of polymer powder to avoid lumps or uneven mixing.

Maintain quality: The quality of polymer powder can be maintained during the mixing process to avoid quality problems caused by uneven mixing.

Improve production efficiency: Through paddle stirring and mixing, production efficiency is improved, time and labor costs are saved.

Wide applicability: Applicable to various polymer powders, including polyethylene, polypropylene, polyvinyl chloride, etc., to meet different production needs.

Easy operation: Simple and convenient operation, easy to control mixing time, speed and temperature, improve the controllability of the production process.

The equipment uses the three-dimensional mixing principle to make the polymer powder and additives reach a uniformity of more than 99% in a short time (5-15 minutes), significantly reducing the agglomeration or stratification of the material.

Uniformity: The design and rotational motion of the paddle blades ensure uniform mixing of the polymer powder and avoid insufficient mixing.

Speed control: By controlling the rotation speed, the mixing speed can be adjusted to meet the requirements of mixing different powders.

Maintaining quality: The quality of the powder is maintained during the mixing process, avoiding quality problems caused by uneven mixing.

It is widely used in different application fields using its own advantages. The following are some common application scenarios.

Chemical industry: Polymer powder for paddle mixer is widely used in the chemical industry to mix various polymer powder raw materials, such as resins, polymer particles, etc.

Plastic industry: Polymer powder for paddle mixer is used to mix plastic particles, plastic additives, etc. to ensure the quality and uniformity of plastic products.

Rubber industry: Polymer powder for paddle mixer is used to mix rubber powder, rubber additives, etc. to improve the production efficiency and quality of rubber products.

Coating industry: Polymer powder for paddle mixer is used to mix coating raw materials to ensure the uniformity of coating pigments, resins and other materials.

As an important mixing equipment, polymer powder for paddle mixer plays an indispensable role in chemical, plastic, rubber and other industries. Its characteristics of uniform mixing, maintaining quality and improving production efficiency make it an indispensable equipment in many production lines, providing companies with reliable mixing solutions, helping to ensure efficient operation of production lines and improve product quality.

In polymer processing and production, the polymer powder paddle mixer is often used with the following equipment:

Screw feeder: It can transport polymer powder from the storage container to the paddle mixer.

Measuring equipment: It is used to accurately weigh the weight of polymer powder and other additives to ensure the accurate proportion of ingredients. For liquid additives such as plasticizers, lubricants, etc., the flow meter can accurately control the amount of addition.

Disperser: When mixing polymer powder, if some agglomerated powder or added block materials need to be dispersed, the disperser can play a role.

Grinding machine: For some polymer powders with high hardness or that need to be further refined, the grinding machine can grind them before or during mixing to reduce the powder particle size, increase the specific surface area, and improve the performance and mixing uniformity of the polymer.

Discharging conveyor: After the mixing is completed, the discharging conveyor can convey the mixed polymer powder to the next process, such as packaging equipment or storage container.

Packaging machine: The mixed polymer powder is quantitatively packaged for storage and transportation.

When selecting equipment for mixing polymer powders, belt mixers and paddle mixers have their own characteristics, which need to be comprehensively considered according to the characteristics of polymer powders, mixing requirements and production scale.

The following is a specific analysis

Mixing of coarse and fine particles: The belt mixer is suitable for a wide range of particle size distribution. For polymer powders mixed with coarse and fine particles, it can achieve a better mixing effect through the movement of the belt, and it is not easy to cause coarse particles to precipitate or fine particles to fly.

Fine-particle polymer powder: For fine-particle polymer powder, the paddle mixer has a better mixing effect, but when the particle size distribution is wide, the stirring action of the paddle may cause excessive crushing or uneven mixing of coarse particles.

Poor fluidity and easy agglomeration: For polymer powders with poor fluidity and easy agglomeration, the gentle stirring method of the ribbon mixer can reduce the damage to the powder structure and help maintain the original state of the powder.

Polymer powder with good fluidity: Paddle mixers are more suitable for polymer powders with good fluidity. The rapid stirring of the paddle blades can make the powders evenly mixed in a shorter time.

Large-scale production: The ribbon mixer is recommended, which has a large processing capacity and can be designed into a large-scale continuous mixing equipment according to production needs. It is suitable for large-scale polymer powder mixing production.

Small production or laboratory: The paddle mixer is recommended, which can be designed as a small desktop or vertical equipment. It is easy to operate and occupies a small area. It is suitable for small batch polymer powder mixing experiments or small production.

Dahan Machinery uses 316L stainless steel and is equipped with a PLC fully automatic control system. The mixing uniformity reaches 99.5% and the temperature control accuracy is ±1℃. The product has passed ISO9001 and CE certification, has a unique anti-stick wall design and modular structure, and covers the processing capacity from 5L laboratory models to 5000L industrial models. The products are exported to more than 30 countries and regions, with an annual production capacity of more than 800 sets. It is a leading brand in the field of polymer mixing. If you also have mixing needs, please feel free to contact us to get a quotation!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.