Polypropylene Particle Ribbon Mixer utilizes a unique ribbon mixing structure and U-shaped trough design to achieve precise and homogeneous mixing of PP base granules with masterbatches, fillers, modifiers, and other multi-component materials. It is a key pre-processing unit in polypropylene processing stages such as modified plastics, injection molding, and extrusion. For mixing 2-5mm PP granules and powder/liquid additives, single/double ribbon composite mixing is employed. The double ribbon model uses inner and outer layers of counter-rotating blades to create axial convection + radial diffusion motion, with a volume ranging from 50L to 10m³. It can flexibly adapt to production capacities from laboratory pilot tests to large-scale production, with mixing time of only 3-8 minutes and a transmission efficiency exceeding 95%. Customized functions such as heating and spraying can also be added as needed.

The core materials for Polypropylene Particle Ribbon Mixers are mainly divided into two categories: stainless steel and carbon steel. Both are designed to meet the wear resistance and compatibility requirements of plastic processing scenarios. Material selection must be based on a comprehensive consideration of raw material characteristics, hygiene requirements, and budget.

Stainless Steel: The core components, including the tank, screw ribbon, and parts in contact with materials, are made of 304 or 316L stainless steel. The surface is polished, smooth, and burr-free, offering excellent corrosion resistance and making it suitable for mixing polypropylene granules containing corrosive additives. It is highly hygienic, easy to clean, and prevents material contamination and residue.

Carbon Steel: The tank is made of thickened carbon steel, with the inner wall treated by sandblasting or painting. The screw ribbon is made of 65Mn spring steel, and non-contact parts are welded from carbon steel. Its core advantages are lower material cost, outstanding cost-effectiveness, high structural strength, and good wear resistance, able to withstand long-term friction between polypropylene granules and common fillers, making it suitable for conventional mixing scenarios.

The Polypropylene Particle Ribbon Mixer boasts significant advantages in the mixing field thanks to its unique design and outstanding performance. It adapts to different production capacity requirements, gently protects materials, exhibits strong compatibility with various materials, and can flexibly adapt to diverse production scenarios.

Strong Adaptability:Utilizing a single/double ribbon composite mixing structure, designed specifically for the characteristics of polypropylene granules and powder additives, it can quickly achieve uniform dispersion of masterbatches, fillers, and PP granules, avoiding color differences or uneven performance in finished products.

Durable Materials:Offering a choice of carbon steel and stainless steel, the ribbons are made of spring steel or wear-resistant alloy, quenched to a hardness of HRC50 or higher, resistant to long-term friction between granules and fillers. The stainless steel model resists corrosive additives, extending the equipment's service life.

Wide Capacity Coverage:From 50L laboratory pilot models to 10m³ large-scale production models, it can meet different production capacity needs. Smaller models are suitable for modified material development, while larger models support continuous feeding in extrusion production lines.

Expandable Functionality: A heating jacket can be added for pre-drying or hot-mixing of polypropylene granules, reducing moisture interference in subsequent processing; a spray device can be added to facilitate the addition of liquid additives.

The Polypropylene Particle Ribbon Mixer excels in mixing due to its unique structure. Its core ribbon agitator system, combined with a rationally designed tank, ensures thorough circulation and mixing of materials within the machine, providing stable and reliable mixing for polypropylene processing.

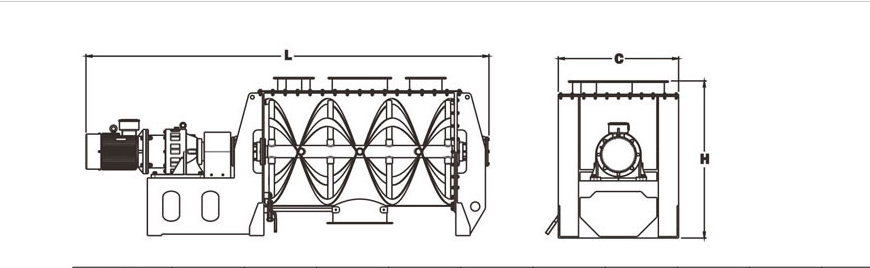

Mixing Tank: The core load-bearing component, featuring a horizontal U-shaped design with a volume ranging from 50L to 10m³. The thickened tank design ensures structural stability, and the smooth inner wall reduces material residue, adapting to the mixing needs of polypropylene granules and powder additives.

Ribbon Agitator Component: The core working unit, with wear-resistant and impact-resistant ribbon blades. Primarily used to push materials towards the center, ensuring uniform mixing and preventing material accumulation.

Transmission System: Composed of a motor, a hardened gear reducer, and a coupling. The motor supports frequency conversion speed regulation, allowing adjustment of the mixing speed as needed. The reducer boasts a transmission efficiency of over 95%, low noise, and smooth operation. The coupling employs a flexible connection to buffer vibration and protect the mixing shaft and motor.

Sealing and Feed/Discharge Structure: Both ends of the mixing shaft are equipped with a dual device of skeleton oil seals and packing seals to prevent dust leakage and material moisture absorption. The feed inlet is equipped with a dust cover or a feeder interface, while the discharge outlet is equipped with a butterfly valve, a rotary valve, or a manual gate valve, selectable according to production capacity requirements.

The Polypropylene Particle Ribbon Mixer achieves rapid mixing through a combined axial convection and radial diffusion mixing motion. After startup, the motor drives the stirring shaft to rotate via a hardened gear reducer. In the double-ribbon model, the inner ribbon pushes the granular material from both ends of the tank towards the center, while the outer ribbon pushes the material from the center back to both ends, forming a closed-loop cycle. The single-ribbon model uses a single-layer ribbon to propel the material axially along the tank, achieving uniform mixing through the particles' own gravity and collision. For mixing polypropylene granules and powder additives, the equipment can optimize the stirring intensity by adjusting the ribbon speed, preventing powder from flying or particle breakage.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

We provide different models of Polypropylene Particle Ribbon Mixers to meet our customers' production needs. From small-scale laboratory tests to large-scale production, from mixing ordinary materials to high-precision process requirements, numerous successful cases demonstrate its superior performance and adaptability.

Automotive PP Production: Companies producing modified PP for automotive exterior parts face the challenge of uneven mixing leading to fluctuations in the impact strength of finished products when mixing PP base granules with glass fiber, flame retardants, and POE elastomer. A 3m³ double-ribbon polypropylene granule mixer has been introduced. This equipment utilizes 65Mn wear-resistant ribbons and a heating jacket, achieving uniform dispersion of glass fiber and PP granules through double-layer counter-current ribbon mixing. Combined with an automatic weighing and batching system, each batch can handle 2.5 tons in just 6 minutes.

Food-Grade PP Packaging Film Factory: To comply with policy requiring the addition of 30% recycled PP granules while ensuring film hygiene and compatibility, a 1000L 304 stainless steel double-ribbon mixer has been selected. The equipment's inner wall is mirror-polished, eliminating dead corners and preventing material residue and contamination, meeting food-grade standards. Through double-ribbon convection mixing, virgin PP, recycled PP, and POE compatibilizer are uniformly mixed in 5 minutes, with the film's interlayer peel strength consistently above 3.5N, showing no delamination.

PP Recycling: Primarily processes recycled materials such as waste plastic crates and films. This involves mixing crushed PP granules with virgin materials and antioxidants. Considering budget and capacity requirements, a 500L carbon steel single-ribbon mixer was selected. The equipment uses a carbon steel tank and wear-resistant ribbons, suitable for mixing scenarios without corrosive additives. Through axial pushing and stirring with a single ribbon, each batch can process 300kg in 4 minutes, increasing efficiency by 50% compared to traditional mixing tanks.

PP/PE Co-extruded Film Production: Facing the problem of poor compatibility between PP and PE and easy film delamination, POE compatibilizer and liquid lubricant need to be added. A 2m³ double-ribbon mixer with a spray device was introduced. The double-layer ribbons create a convection + shearing composite motion, ensuring uniform mixing of PP, PE granules, and POE compatibilizer. Simultaneously, the spray device precisely sprays liquid lubricant.

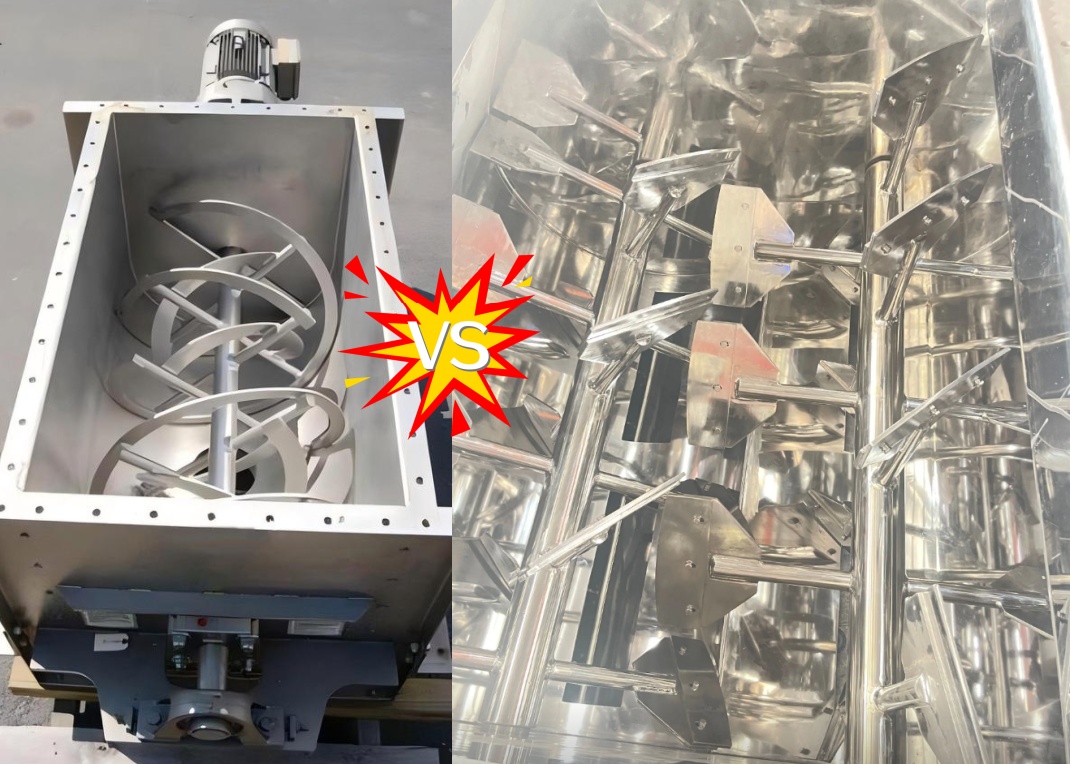

In polypropylene particle mixing operations, ribbon and paddle mixers differ significantly in mixing effect, material compatibility, and application scenarios due to their different structural designs and working principles.

Structure: Ribbon mixers use a horizontal U-shaped tank with a single/double ribbon agitator. Paddle mixers typically have a vertical or horizontal tank with plow-type or blade-type agitator blades.

Mixing Method: In double-ribbon mixers, the inner ribbon pushes the material towards the center while the outer ribbon pushes it back, creating a combined motion. Single-ribbon mixers push the material axially, relying on particle gravity and collision to achieve homogenization, resulting in stable mixing and emphasizing full-area circulation and gentle mixing. Paddle mixers rely on the strong shear force and turbulence generated by the high-speed rotation of the paddles to throw and disperse the material before mixing.

Mixing Performance: Ribbon mixers, through closed-loop material circulation, can precisely disperse polypropylene particles and additives, achieving a mixing uniformity CV ≤ 2%, making them suitable for mixing trace amounts of additives. Paddle mixers, on the other hand, have a uniformity CV ≤ 3-4%, and are slightly less effective at dispersing trace amounts of additives.

Material Compatibility: Ribbon mixers are compatible with materials of various particle sizes and densities; paddle mixers are more suitable for simple mixing of granules and powders, but are less effective at handling sticky materials.

Production Efficiency: Ribbon mixers have a mixing time of 3-8 minutes, a volume range of 50L-10m³, and lower unit energy consumption. Paddle mixers have a faster mixing speed, requiring only 1-5 minutes, but larger-capacity models have poor operational stability and higher energy consumption.

Application Scenarios: Ribbon mixers are the preferred choice for modified PP production, food-grade PP processing, co-extrusion film raw material mixing, and recycled material regeneration, meeting the stringent requirements for uniformity and particle integrity in automotive modified PP and food contact grade products.

Choosing the right polypropylene particle ribon mixer requires comprehensive consideration of core dimensions such as production needs, material characteristics, and process requirements to ensure equipment compatibility, stability, and economy.

Define production capacity requirements: The equipment volume can be determined based on daily production batches. For laboratory pilot tests or small-batch production with a daily output ≤ 5 tons, a 50L - 500L small model is suitable; for medium-scale production with a daily output of 5 - 50 tons, a 1000L - 3m³ model is suitable; for large-scale production with a daily output ≥ 50 tons, a 5m³ - 10m³ large model is recommended. Simultaneously, it should match the continuous feeding requirements of the production line, reserving 10% - 20% volume redundancy.

Material and Structure Selection: For mixing ordinary PP granules and non-corrosive additives with a limited budget, choose a carbon steel model. For food-grade PP processing, processing with corrosive additives, or in humid environments, a 304 stainless steel model is required; for high-end corrosion resistance, upgrade to 316L stainless steel. Regarding the ribbon structure, for mixing single PP granules with masterbatch, choose a single-ribbon model; for mixing multi-component raw materials, materials with large specific gravity differences, or materials containing trace additives, prioritize a double-ribbon model.

Functional Configuration: If pre-drying of PP granules is required, choose a model with a heating jacket, controlling the temperature from 50-120℃; for adding liquid additives, install a spray system; for high hygiene requirements, choose a model with a mirror-polished inner wall; for continuous production scenarios, choose a model that can be linked with a feeding machine, weighing system, and extruder, supporting automated control.

Production Scenario Matching: When frequently changing formulas, prioritize models with low residue rates and easy cleaning to avoid cross-contamination; for limited production space, choose horizontal, compact models that take up little space and are easy to install and debug; small and medium-sized enterprises can choose modular design models, which can be equipped with functional components later, reducing initial investment costs.

As a source manufacturer, our Polypropylene Particle Ribbon Mixers start at $1000, with a clear and transparent pricing system tailored to different production needs. Price differences mainly stem from equipment models, ranging from 50L laboratory pilot models to 10m³ large-scale production models. Prices adjust gradually as volume increases and configurations upgrade. Basic models cover standard configurations such as carbon steel/304 stainless steel materials and single/double ribbon structures, meeting routine mixing needs. For customized functions, such as adding a heating jacket, spray device, upgrading to 316L stainless steel, or configuring an automated control system, the price will increase reasonably from the basic model. A precise quote can be provided based on your production capacity and process requirements. Direct supply from the manufacturer eliminates intermediaries, ensuring both cost-effectiveness and equipment quality.

We will recommend models based on a comprehensive consideration of the customer's production needs and material characteristics. For example, we select the appropriate ribbon type and speed based on parameters such as material viscosity, density, and particle size; and determine the equipment's volume and power parameters based on production scale. Furthermore, to meet the personalized needs of different users, we can provide customization services. We can customize ribbon mixers to meet specific production environment and process requirements. For example, we can customize jacketed ribbon mixers with heating and drying functions; ribbon mixers with special atomizing liquid nozzles; and we can change the position and direction of the discharge port, add roller designs, etc.

With its targeted structural design, high-speed mixing performance, and wide range of applicable scenarios, the Polypropylene Particle Ribbon Mixer provides a reliable mixing solution for the polypropylene plastics processing industry, helping companies improve product quality and reduce production costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.