Cat Litter Ribbon Mixer is a specialized mixing device designed for cat litter production. It utilizes a U-shaped cavity and a dual-ribbon mixing system. The outer ribbon pushes the material along the cavity wall to the center, while the inner ribbon feeds the material in the opposite direction to both sides, creating forced convection to achieve homogeneous mixing of the raw materials. Its core function is used in the production of bentonite, tofu cat litter, and blended cat litter, thoroughly mixing basic raw materials with deodorizers, binders, and other auxiliary materials to ensure stable absorbency and clumping properties of the cat litter.

Our Cat Litter Ribbon Mixer supports non-standard customization. Materials include stainless steel or wear-resistant alloy carbon steel. Mixing capacity ranges from 100L to 5000L, adjustable to suit different production needs. Mixing time is short, completing uniform mixing in 3-8 minutes with a mixing uniformity of over 99%. Prices start at $1200. Basic models meet the needs of small workshops, while high-end customized models can be equipped with features such as spraying, dust removal, and rollers, providing flexible mixing solutions for cat litter businesses of different sizes.

The choice of materials for Cat Litter Ribbon Mixers depends on production needs and hygiene standards. Common options include carbon steel and stainless steel.

Carbon steel cat litter ribbon mixers: Lower cost and high strength, suitable for basic cat litter production with less stringent hygiene requirements, such as bentonite cat litter, which has low moisture content and low corrosivity. However, carbon steel has limited corrosion resistance and is prone to rusting with prolonged contact with damp or acidic materials, requiring anti-corrosion paint or plating to slow down corrosion.

Stainless steel cat litter ribbon mixers: Strong corrosion resistance, easy to clean, excellent hygiene performance, and compliant with food and pharmaceutical industry standards. Its smooth surface reduces material residue and prevents bacterial growth, making it particularly suitable for producing tofu cat litter, high-end blended cat litter, or export-oriented products. It prevents metal ions from reacting with additives and supports a jacketed temperature control system, compatible with various processes.

The Cat Litter Ribbon Mixer is custom-designed based on the characteristics of cat litter raw materials such as bentonite, plant fiber, and activated carbon, balancing mixing efficiency and material protection to ensure consistent quality in every batch of cat litter.

Wear-resistant and durable: Parts in contact with materials are made of thickened 304 stainless steel, with some models offering an optional wear-resistant alloy coating. This resists frictional wear from hard raw materials like bentonite, extending the equipment's lifespan.

Double-ribbon convection: The core mixing structure features a double-ribbon design. The outer ribbon pushes the cat litter raw material along the cylinder wall towards the center of the chamber, while the inner ribbon pushes the material in the opposite direction to both sides, creating a strong forced convection circulation. This mixing method quickly breaks up bentonite clumps, allowing the base raw materials to fully blend with deodorizers, antibacterial agents, fragrances, and other trace additives, achieving uniform mixing within 3-8 minutes.

Compatible with multiple cat litter types: Whether it's bentonite cat litter, tofu cat litter (plant fiber + starch), or mixed cat litter (bentonite + tofu granules), the equipment can adapt to different material characteristics through variable frequency speed control (speed adjustable between 40-120 rpm).

Flexible customization: Customized functions can be added according to the cat litter production process. For example, for highly viscous tofu cat litter raw materials, a spray device can be added for precise addition of binders; for the production of dusty bentonite cat litter, a dust removal system can be equipped to reduce dust pollution; and a roller design can be added for easy equipment movement and adjustment of workshop layout, improving production flexibility.

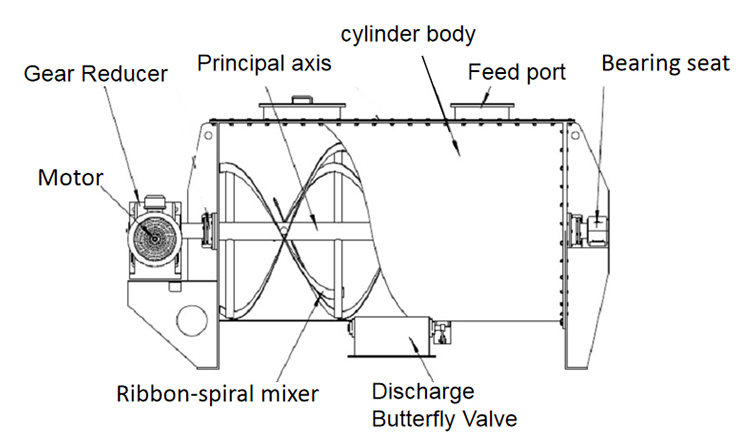

The Cat Litter Ribbon Mixer's structure is designed around the characteristics of cat litter raw materials. Its core consists of five main components, ensuring wear resistance, efficient mixing, and easy operation, suitable for the production needs of bentonite, tofu, and other types of cat litter.

Mixing Chamber: Utilizes a U-shaped groove structure with a polished inner wall, smooth and free of dead corners, reducing cat litter residue and buildup; volumes from 100L to 5000L are customizable, with sealed end caps at both ends to prevent dust spillage.

Mixing System: The core is a double-layer spiral ribbon assembly. The outer spiral ribbon pushes material along the chamber wall to the center, while the inner spiral ribbon feeds material in the opposite direction to both sides, forming a forced convection circulation. The spiral ribbon is made of high-strength, wear-resistant material, quickly breaking up clumps and ensuring uniform mixing of cat litter raw materials and additives, suitable for the production of different types of cat litter.

Transmission System: Composed of a motor, reducer, and coupling, providing stable power to the mixing shaft. Supports variable frequency speed control, allowing adjustment of the speed according to the characteristics of the cat litter material, preventing raw material breakage or uneven mixing.

Feed Inlet: Located at the top of the chamber, it can connect to a feeder or feeding station. Some models are equipped with a screening device to remove impurities from the raw materials.

Discharge Inlet: Located at the bottom of the chamber, equipped with a pneumatic/manual valve to control the discharge speed and prevent clumping of sticky cat litter.

The Cat Litter Ribbon Mixer uses a horizontal U-shaped chamber as its carrier. A motor-driven reducer rotates a double-ribbon shaft. The outer ribbon pushes the cat litter raw material along the chamber wall towards the center, while the inner ribbon pushes the material in the opposite direction to both sides, creating strong forced convection. During the process, the material is continuously sheared and mixed, quickly breaking up clumps and ensuring thorough integration of the base raw materials with deodorizers, binders, and other auxiliary materials. Uniform mixing can be achieved within 3-8 minutes.

The Cat Litter Ribbon Mixer can process powders, semi-fluids, and viscous materials. Its low energy consumption and high uniformity characteristics make it particularly suitable for the uniform mixing requirements of raw materials such as bentonite and tofu residue in cat litter production.

Bentonite Cat Litter Production: Mixing bentonite, sodium carbonate (a clumping agent), deodorizer, and fragrance ensures the cat litter has strong absorbency, compact clumping, and uniform odor control.

Tofu Cat Litter Production: Mixing tofu residue/plant fiber powder with starch (a binder) and antibacterial agents ensures good formability and resistance to breakage, while achieving uniform distribution of antibacterial components.

Mixed Cat Litter Production: Uniformly mixing bentonite granules and tofu granules, combined with deodorizer, leverages the advantages of both types of cat litter, avoids segregation, and improves user comfort.

Functional Cat Litter Production: Such as activated charcoal cat litter and probiotic cat litter, precisely mixing activated charcoal powder, probiotic preparations, and basic raw materials ensures the stable functioning of functional ingredients.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The Cat Litter Ribbon Mixer typically takes between 30 seconds and 15 minutes to mix in a single batch, depending on the characteristics of the cat litter raw materials, equipment configuration, and required mixing precision. For free-flowing raw materials such as dry bentonite, the dual-ribbon forced convection design enables rapid homogenization, completing mixing in just 30 seconds to 3 minutes. When mixing sticky tofu cat litter raw materials or adding trace amounts of deodorizers, the mixing time needs to be extended to 3-8 minutes to ensure uniform dispersion. The equipment supports variable frequency speed control, allowing for optimized mixing time by adjusting the rotation speed. Combined with an optimal fill rate of 50%-70%, it balances efficiency and product quality while ensuring mixing uniformity, adapting to different production scales.

The Cat Litter Ribbon Mixer enables solid-liquid mixing, particularly suitable for the mixing needs of "solid raw materials + liquid additives" in cat litter production, such as the mixing of plant fiber powder and starch binder in tofu cat litter production, and the blending of base powder and moisturizing liquid in bentonite cat litter. The equipment, through a customized spraying device, evenly atomizes and sprays liquid additives onto the rotating solid raw materials. Combined with double-ribbon forced convection stirring, the liquid quickly blends with the solid materials, preventing localized clumping. During the mixing process, the stirring intensity can be controlled via frequency conversion speed regulation, ensuring both thorough homogenization of the solid and liquid components and protecting the integrity of the solid raw materials, fully meeting the solid-liquid mixing process requirements of cat litter production.

The Cat Litter Ribbon Mixer can be deeply integrated with feeding machines, pellet mills, and packaging machines to build a fully automated cat litter production line. The three work together to achieve full automation from raw material processing to finished product packaging.

Feeding Machine: Precisely feeds bentonite, tofu residue, and other raw materials to the mixer according to a preset ratio, avoiding human error. Its core advantages lie in flow matching and anti-clogging design. The variable frequency speed-regulating screw feeder ensures that each batch of raw materials enters the mixer evenly within 5 minutes, preventing material accumulation or supply interruptions.

Pelletizer:Presses the mixed material into cat litter pellets with a particle size of 2-6mm, enhancing product uniformity. Its process continuity is reflected in its direct connection with the mixer: the mixed material enters the pelleting chamber within 10 seconds of exiting the discharge port, preventing temperature and humidity loss; the die size and pressure are adjustable to meet the different needs of bentonite cat litter and tofu cat litter.

Packaging Machine:Automatically weighs, bags, and seals the granulated cat litter, and integrates production information printing functions. Its seamless design connects to the pelletizer discharge port via a conveyor belt; a 2-ton-per-hour production line can package 8-10 bags per minute; for highly hygroscopic bentonite cat litter, composite film and nitrogen filling technology are used to effectively isolate moisture.

Choosing the right Cat Litter Ribbon Mixer requires a comprehensive assessment of core needs, including cat litter type, production capacity, and raw material characteristics. This ensures the equipment is compatible with the production process, balancing efficiency and quality.

Production Capacity Matching: Select an appropriate capacity model based on daily output. For small-scale trial production, 100-300L is suitable; for medium-scale mass production, 500-1000L is appropriate; and for large factories, 2000-5000L is suitable.

Material Characteristics: When mixing hard raw materials such as bentonite, choose a wear-resistant material. When mixing sticky raw materials such as tofu cat litter, a spraying device is required. When mixing raw materials containing particles, confirm the ribbon strength.

Core Configuration: Prioritize a double ribbon structure to ensure mixing uniformity ≥95%, guaranteeing consistent absorbency and clumping properties of the cat litter. For dusty environments such as bentonite production, a dust collection system can be added to meet environmental protection requirements.

As a professional manufacturer, we provide customized mixing equipment for pet product companies, helping bentonite cat litter and tofu cat litter production lines achieve uniform mixing. Our equipment is renowned for its low residue and high stability, with a customer repurchase rate exceeding 98%.

Tofu Cat Litter Workshop: Facing problems such as high dust levels from manual feeding and uneven mixing leading to poor litter clumping, they adopted a 300L double-ribbon mixer. The equipment features a 304 stainless steel chamber and a simple dust removal interface, and is equipped with casters for easy movement in confined workshops. The double-ribbon structure improves the mixing uniformity of tofu residue powder, starch binder, and deodorizer to 98%, reducing the mixing cycle from 30 minutes of manual stirring to 6 minutes, and increasing single-shift output from 200kg to 800kg. The equipment investment cost is moderate, and operation is simple, requiring only 1-2 people to complete production.

Bentonite Cat Litter Factory: To expand production capacity to handle e-commerce orders, their existing equipment suffered from low mixing efficiency and severe dust pollution. The system incorporates a 1000L double-ribbon mixer, paired with a screw conveyor and pulse dust collector, to achieve automatic raw material conveying and dust collection. The equipment uses a thickened stainless steel cavity and wear-resistant ribbons to resist bentonite abrasion, achieving a 99% mixing uniformity and ensuring stable absorbency of the cat litter. Variable frequency speed control adapts to different mesh sizes of bentonite, preventing over-grinding. The entire system reduces single-batch mixing time to 5 minutes, increasing daily output from 3 tons to 8 tons.

Large-scale mixed cat litter companies: Specializing in bentonite + tofu mixed cat litter, requiring frequent formula changes and uniform mixing of granules and powders. They utilize a 2000L customized double-ribbon mixer, equipped with a spray device for precise addition of humectants, and a weighing and batching system for automatic raw material metering. The powerful convection design of the double-ribbon mixer solves the problem of stratification in the mixed cat litter, achieving a 99% granule integrity retention rate after mixing. The equipment supports multiple formula storage and features a CIP cleaning system for rapid cleaning during production changes, reducing changeover time to 30 minutes.

We are a professional manufacturer with many years of experience in the field of cat litter mixing equipment, specializing in the R&D, production, and non-standard customization of Cat Litter Ribbon Mixers. The core components of our equipment are made of wear-resistant stainless steel, and the double-ribbon structure ensures a mixing uniformity of ≥99%, suitable for the production of all types of cat litter, including bentonite, tofu, and mixed cat litter. We support professional customization based on customer needs, covering capacities (100L-5000L), mixing speeds, spray/dust removal/roller functions, etc., and can also be connected to feeders and granulators to build complete production lines. Our products are ISO quality certified, and we provide comprehensive services including commissioning, technical training, and after-sales maintenance, offering customized solutions and reliable quality.

With its precise mixing performance, wear-resistant and durable structural design, and high-speed production capacity, the Cat Litter Ribbon Mixer has become an indispensable core piece of equipment in the modern cat litter industry. It not only solves the industry pain points of uneven mixing and high residue in cat litter raw materials, but also adapts to the production needs of cat litter of different scales and types through flexible customization design and safe and convenient operation, providing reliable support for enterprises to ensure product quality and improve production efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.