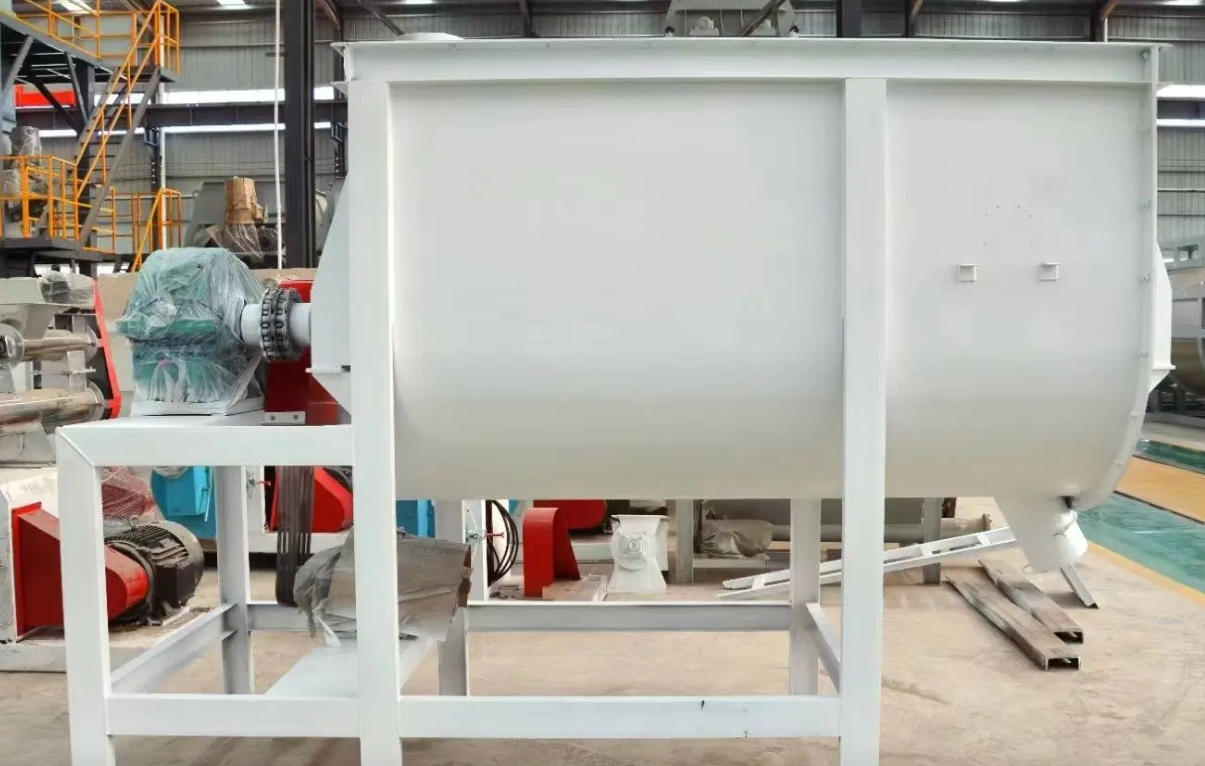

Ribbon Mixer For Instant Food Additives features a U-shaped horizontal barrel and a twin-ribbon mixing system. It quickly dissolves and mixes various instant food additives with near-100% mixing efficiency, ensuring consistent and consistent product quality throughout each batch. It supports the flexible addition of different additives to meet complex formulation requirements. Customized systems, including single-shaft and twin-shaft ribbons, as well as heating and water-cooling options, are available to provide the right mixing solution tailored to your site needs.

The Ribbon Mixer for Instant Food Additives (RFA) is designed with a body and material-contacting parts made of 304 stainless steel, which prevents chemical reactions between additives and metal materials. The device can also withstand moist additives at humidity levels of 60%-75%, preventing material from sticking to the wall and deteriorating. It is suitable for use in scenarios such as instant noodle seasoning packets and premixing instant porridge additives.

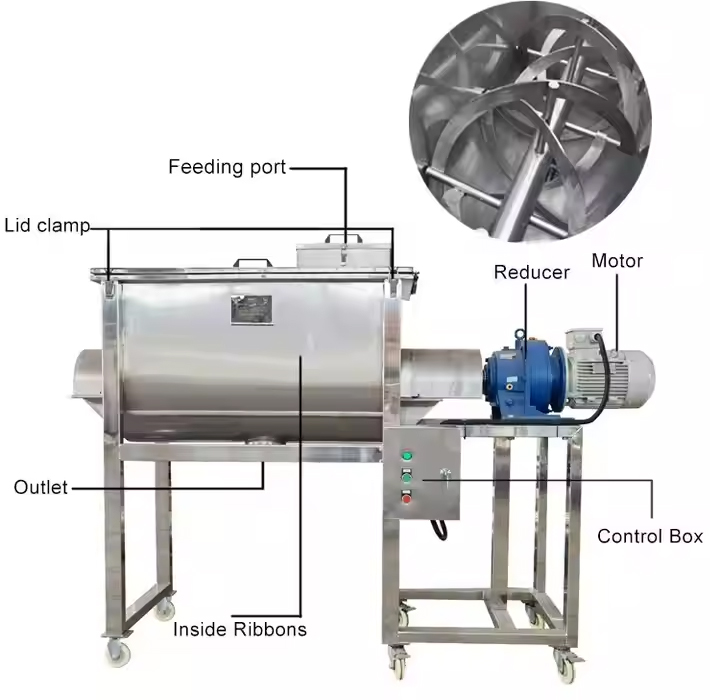

This ribbon mixer for instant food additives quickly and evenly mixes additive powders, improving production efficiency. Its agitator design reduces energy consumption. Its structure ensures thorough contact and dispersion of powders, and the equipment is easy to operate: simply add materials and set parameters. The stainless steel drum and agitator are easy to clean, meet food hygiene requirements, and simplify maintenance. High-quality materials and rigorous craftsmanship ensure high reliability and durability, ensuring long-term stable operation. It supports single-shaft and dual-shaft mixing, and the discharge port can be repositioned (bottom or side), allowing for customization to meet diverse production needs.

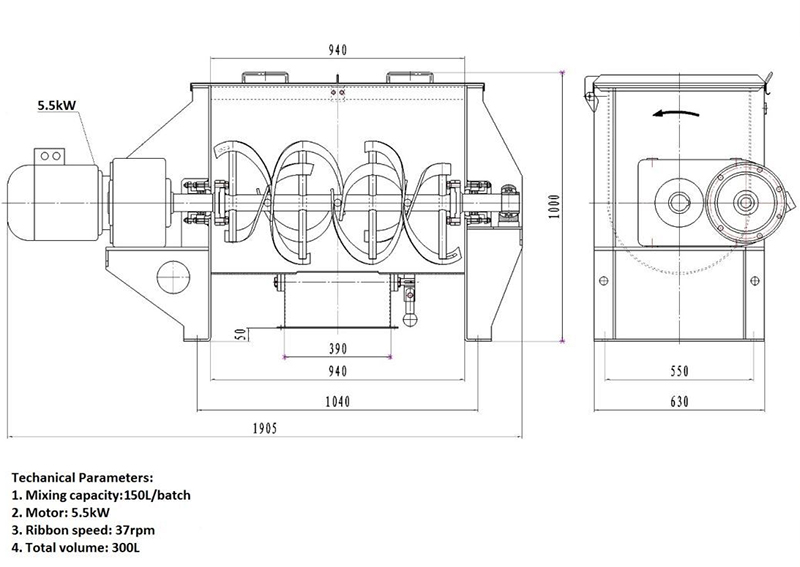

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Ribbon Mixers for Instant Food Additives are widely used in the production of various convenience foods. In instant noodle production, they mix seasoning powders, spices, and food additives, ensuring even seasoning distribution and a consistent taste. In instant rice production, they blend seasonings, vegetable powders, and sauces to create a rich, vibrant rice aroma. In instant soups, they evenly blend various seasonings and powders to ensure a consistent taste. In instant breakfast food production, they blend various grains, dried fruits, honey, and other ingredients to create nutritious and balanced products. In instant condiment production, they can also be used to mix seasoning powders such as chicken broth, soy sauce powder, and chili powder to enhance flavor.

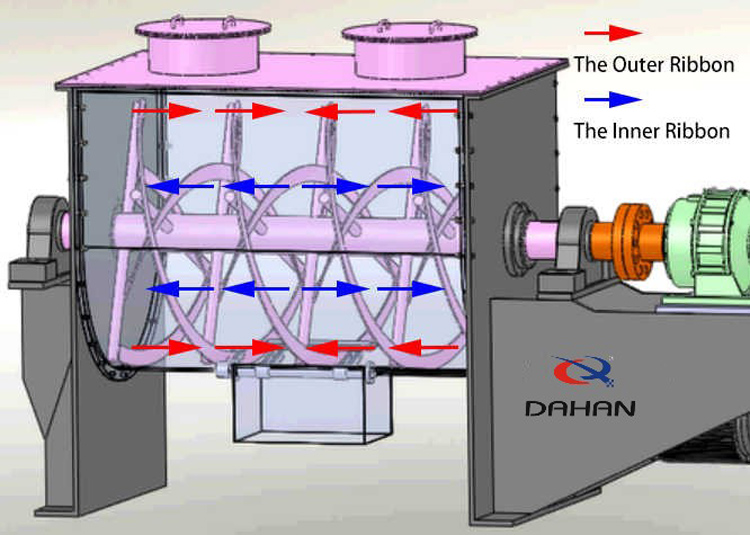

The ribbon mixer's structural design is centered around mixing and practical needs. Its core mixing components are double-layered ribbons. The inner layer rotates counterclockwise to push material to the ends, while the outer layer rotates right-hand to gather material toward the center. The mixing drum is U-shaped or trough-shaped, with a finely polished interior, providing ample mixing space while facilitating material flow and cleaning. The drive system, consisting of a motor, reducer, and coupling, provides stable power for mixing. The inlet and outlet are convenient, with a top inlet for easy feeding and a special valve at the bottom outlet for smooth discharge. It can also be equipped with an explosion-proof motor for use with flammable and explosive materials. Some models feature universal wheels for increased mobility to meet diverse production needs.

Ribbon Mixers for Instant Food Additives are widely used in the production of various convenience foods. In instant noodle production, they can mix seasoning powders, spices, and food additives, ensuring even distribution of seasonings and a consistent taste and texture. In instant rice production, they can mix seasonings, vegetable powders, and sauces to create a rich and vibrant rice flavor. In instant soups, they can evenly blend a variety of seasonings and powders to ensure a consistent taste and texture. In the production of instant breakfast foods, they can blend various grains, dried fruits, honey, and other ingredients to create a rich and nutritionally balanced product. In the production of instant condiments, they can also be used to enhance the flavor by mixing seasoning powders such as chicken bouillon, soy sauce powder, and chili powder.

A Ribbon Mixer for Instant Food Additives is a critical piece of equipment for mixing powdered, granular, or liquid materials in the food industry. Equipment selection and maintenance are crucial to ensure efficient and stable operation and meet production needs.

Capacity: The selection depends on the production scale. For small-scale production or laboratory applications, a small capacity model (100-500L) is recommended. For medium-scale production, a 500L-1000L model is recommended to balance efficiency and space usage. For large-scale production, a 1000L-2000L or larger capacity model is recommended for large-scale continuous production.

Considering material characteristics: For lighter materials like milk powder and coffee powder, a slightly larger capacity model can be selected to utilize more space for adequate material dispersion. For heavier materials like seasoning powders and nutritional supplements, there's no need to pursue a large capacity; instead, the selection should be based on the actual batch processing volume.

Material Selection: Food-grade stainless steel is preferred. 304 stainless steel offers excellent corrosion resistance and hygienic properties, meeting the mixing requirements of most food additives and is suitable for mixing common seasoning powders and grain ingredients. 316L stainless steel offers even greater corrosion resistance and higher hygienic standards, making it suitable for mixing highly corrosive or hygienic materials such as acidic seasoning powders and pharmaceutical-grade raw materials.

Additional Functions: Optional functions can be added based on the material and process requirements. For materials that require heating, a model with a heating function can be selected to enhance mixing efficiency through temperature control. For materials that require cooling, such as heat-sensitive food additives, a model with a cooling function is suitable to prevent thermal deterioration.

As a leading manufacturer of Ribbon Mixers for Instant Food Additives, we serve customers across a wide range of industries and offer customized mixing solutions tailored to their production needs. Below are some examples of user experiences from various industries.

Instant noodle seasoning factory: The mixer needs to mix salt, sugar, spices, and trace additives, and must be compatible with the existing production line's side-feed layout. Customized Solution: A 304 stainless steel twin-shaft ribbon mixer was selected, with the feed port moved from the conventional top to the side to accommodate the production line's conveying pipes. To address the tendency of trace additives to agglomerate, dispersing teeth were added to the end of the ribbon, increasing mixing uniformity to 99%. The batch processing capacity was customized to 800L.

Instant breakfast cereal factory: The mixer needs to mix cereal, freeze-dried fruit pieces, and honey, and the addition of honey can easily cause sticking to the wall. Customized Solution: A single-shaft ribbon mixer with a spray system is used, with an atomizing nozzle installed on top to precisely spray honey and prevent localized clumping. A food-grade anti-stick coating is applied to the inner wall of the mixing drum, reducing sticking to less than 0.2%. Taking into account the different specific gravity of grains and fruit, the ribbon speed is adjustable, allowing for low-speed mixing to protect the integrity of the fruit. The capacity is customized to 500L.

Convenient seasoning factory: Producing acidic soy sauce powder requires high hygiene standards and the need to prevent equipment corrosion. It also requires integration with an automated packaging line. Customized Solution: The entire machine is constructed of 316L stainless steel, which is acid-resistant and meets food hygiene standards. The discharge port is customized with a bottom-angled design and a pneumatic valve, ensuring seamless integration with the packaging line and reducing product residue. Given the moisture absorption characteristics of soy sauce powder, a constant temperature jacket is installed on the outer surface of the mixing drum to prevent moisture absorption and clumping.

The Ribbon Mixer for Instant Food Additives is a key piece of equipment in the production of instant foods. Its dual-ribbon convection mixing design allows for efficient and uniform mixing of seasoning powders, spices, cereal ingredients, and more. Its energy-saving design and ease of operation ensure both precise mixing of small and medium-sized batches and the scaled-up operation of large production lines.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.