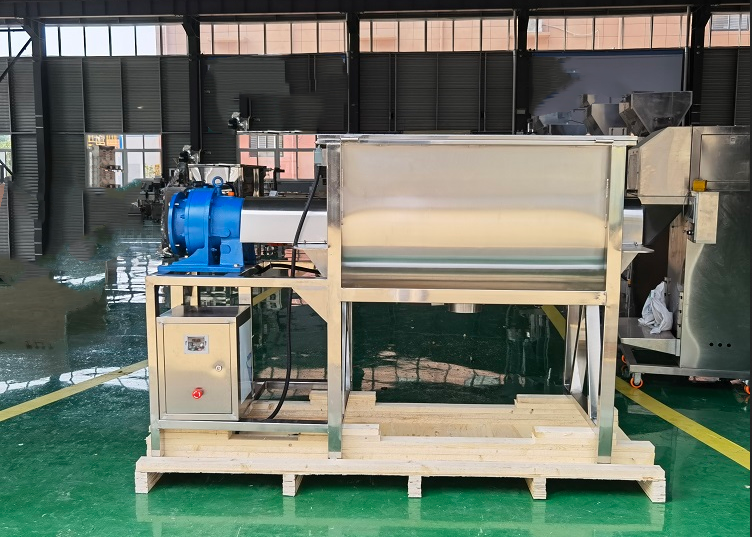

Silicon Carbide Powder Ribbon Mixer is a core mixing device for the abrasives, semiconductor, and refractory industries, solving the mixing challenges of high-hardness silicon carbide powder. It offers a variety of material compatibility options to meet diverse powder requirements. It also covers a single mixing capacity of 50-1000L, adapting to small-batch R&D and large-scale production scenarios. It also supports full-dimensional customization, including adjustable ribbon helix angles, sealing systems, liquid addition ports, cooling jackets, and other functional modules based on process requirements. This ensures high mixing capacity and flexibility.

The Silicon Carbide Powder Ribbon Mixer offers outstanding mixing advantages due to its high hardness. It supports high mixing volumes of 50-1000L and offers customizable ribbon angles, sealing systems, and other features, meeting the needs of both small- and medium-batch R&D and large-scale production, ensuring mixing quality and stability.

Fast Mixing: To address the problems of silicon carbide powder agglomeration and large specific gravity differences (such as mixing different particle sizes), this device achieves rapid mixing through convection circulation between inner and outer double-layered ribbons.

High mixing uniformity: Over 98% can be achieved, and mixing time is 25%-30% shorter than traditional single-shaft mixers.

Supports Multiple Material Mixing: The device supports both "powder + powder" and "powder + a small amount of liquid (such as a binder)" mixing modes, meeting the precise mixing requirements of "base powder + abrasive powder + additives" in silicon carbide abrasive tool production.

Convenient Discharge: A fully open bottom discharge valve, combined with a polished interior, achieves a discharge residue rate of ≤0.2%, reducing material waste and cross-contamination.

Customization: We can tailor the height, inlet and outlet locations, and contact material requirements to meet your production needs.

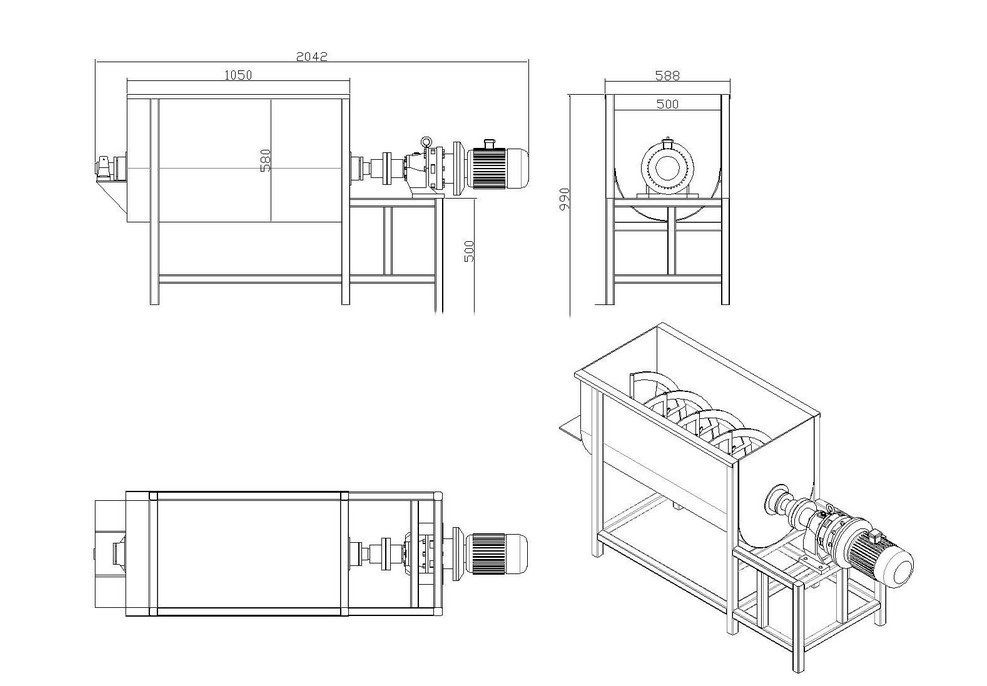

The core of the ribbon mixer lies in its unique double-helix structure. The equipment features a U-shaped cylinder design with two sets of counter-rotating blades: an outer spiral and an inner spiral. The outer spiral blades rotate clockwise, gathering the material from the sides of the cylinder toward the center; the inner spiral blades rotate in the opposite direction, dispersing the material from the center to the sides. The counter-rotating, synchronized motion of the two spirals creates a multi-dimensional vortex, ensuring continuous cross-contact of the materials in three dimensions. For example, when mixing silicon carbide micropowder with a binder, the outer spiral pushes the powder toward the center, while the inner spiral conveys the binder in the opposite direction. The collision between the two creates a uniform liquid bridge structure, ensuring that every silicon carbide particle is fully encapsulated by the binder.

The silicon carbide powder ribbon mixer is designed around the core principles of wear resistance, leak resistance, and rapid mixing. Its structure is divided into five core systems to adapt to the high-hardness characteristics of the powder.

The wear-resistant mixing cylinder: Mostly a horizontal U-shaped structure, the inner wall can be constructed of high-chromium wear-resistant steel or 316L stainless steel with tungsten carbide spray coating to reduce wear on the silicon carbide. Double-ribbon mixing system: The inner and outer ribbons spiral in opposite directions, made of the same material as the barrel. The ribbon edges are rounded to prevent powder stagnation.

Sealing system: A double-layer labyrinth seal and inflatable seal are used. Dust-proof structures are installed at the feed inlet and shaft end to prevent leakage of ultrafine silicon carbide powder.

Discharge and control system: A fully open, wear-resistant discharge valve is installed at the bottom to reduce residual rate. The system is equipped with a PLC control cabinet, which allows for programmable mixing time and speed, and some systems support remote monitoring.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Based on its wear-resistant and anti-pollution core design, the Silicon Carbide Powder Ribbon Mixer is suitable for mixing three types of high-hardness or specialty powders in addition to its main materials.

High-hardness industrial abrasives: Alumina powder, diamond powder, corundum powder, and silicon nitride powder can be mixed. This material has a Mohs hardness of 8-9.5, close to that of silicon carbide. The equipment's high-chromium wear-resistant steel or tungsten carbide spray-coated components withstand wear, and a reinforced sealing system prevents leakage of ultrafine abrasives. The mixing uniformity meets the process requirements for mold manufacturing.

Refractory powders: Suitable for mixing with magnesium oxide powder, zirconium oxide powder, cordierite powder, and graphite powder. Refractory materials are often compounded with silicon carbide to enhance high-temperature resistance. The equipment's horizontal double-ribbon structure enables homogeneous mixing of powders of varying specific gravities, and its stainless steel construction prevents the introduction of impurities, ensuring stable refractory performance.

Special functional powders: Suitable for mixing with ceramic-based composite powders, electronic-grade packaging powders, and cermet powders. The equipment's 316L stainless steel construction meets cleanliness requirements, and its low-speed mixing speed of 12-20 rpm prevents functional powder degradation due to frictional heating.

When mixing silicon carbide powder, the material selection for the ribbon mixer should comprehensively consider the material's corrosiveness, hardness, and process requirements. 304 or 316L stainless steel is recommended for material contact areas. Its corrosion resistance and easy cleanability prevent metal ion contamination, making it particularly suitable for high-purity silicon carbide production. For non-corrosive environments or to control costs, Q235 carbon steel with a paint finish offers an economical solution, but requires regular maintenance to prevent rust. Furthermore, specialized processes (such as lithium battery materials) may require custom coatings or alloys to accommodate high temperatures and inert gas atmospheres.

To select the right silicon carbide powder ribbon mixer, you must first determine the core based on the powder's characteristics, select the specifications based on production capacity, and finally, determine the functionality based on the process. For cleanliness requirements, choose a model with a polished interior. For temperature control, add a cooling jacket. Customization is essential to ensure optimal production fit.

Based on silicon carbide powder characteristics: Contact component materials are selected based on powder purity and particle size. Semiconductor-grade high-purity powders require stainless steel and tungsten carbide spray-coated components, along with double-layer sealing to prevent contamination. Industrial-grade powders can be made with high-chromium wear-resistant steel to balance cost and wear resistance.

Based on production capacity: Small and medium-volume production (50-200 kg per batch) is suitable for small horizontal machines, which are compact and flexible, ideal for laboratory R&D or small processing plants. Large-scale production (200-1000 kg per batch) requires a large dual-motor drive model.

Select functional modules based on process requirements: For cleanliness requirements, choose a machine with a polished interior and a seamless design to minimize cross-contamination. Mixing ultrafine powders that heat easily requires a cooling jacket. Assembly line production can be equipped with a PLC control system and remote monitoring for precise parameter setting and data traceability.

Dahan Machinery is a professional manufacturer specializing in the research, development, and production of Silicon Carbide Powder Ribbon Mixers. With years of experience in the industry and numerous patented technologies, Dahan Machinery specializes in customizing silicon carbide powder ribbon mixers based on the purity, particle size, and mixing form of the customer's silicon carbide powder. We can customize the materials of core components and optimize the ribbon helix angle from 15° to 20°. We also offer comprehensive adjustments to the mixing chamber capacity (50-1000L), sealing system, and control system to meet the needs of diverse production lines. The equipment features a modular structure with universally interchangeable wearing parts, minimizing maintenance costs.

The Silicon Carbide Powder Ribbon Mixer, with its high speed, precision, and low residue, has become an indispensable core equipment in the high-end manufacturing industry. From powder metallurgy to semiconductor materials, from ceramic manufacturing to new energy, its three-dimensional convection mixing technology is continuously driving industrial production towards higher quality and lower costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.