Spices ribbon mixer is a mixing device developed for the fragrance industry. targeting the characteristics and mixing needs of fragrance powders and granules, it employs a horizontal U-shaped tank and a spiral ribbon mixing structure to achieve precise and homogeneous mixing of various fragrance raw materials. The design focuses on high uniformity, low residue, and prevention of flavor cross-contamination, making it a key piece of equipment for ensuring stable flavor and consistent quality in fragrance products.Spices ribbon mixer is a mixing device developed for the fragrance industry. Targeting the characteristics and mixing needs of fragrance powders and granules, it employs a horizontal U-shaped tank and a spiral ribbon mixing structure to achieve precise and homogeneous mixing of various fragrance raw materials. The design focuses on high uniformity, low residue, and prevention of flavor cross-contamination, making it a key piece of equipment for ensuring stable flavor and consistent quality in fragrance products.

The Spices ribbon mixer is fully customizable, allowing adjustment of the ribbon spiral angle and speed according to the type of fragrance, including powders, granules, and fragrances containing a small amount of oil. It supports roller design and universal casters with brakes, allowing for easy relocation without disassembly after use, making it flexible and adaptable to multiple workstations in a workshop. The machine's single-batch mixing capacity ranges from 50L to 800L. Small-to-medium capacity models are suitable for small-batch pilot production, while large-capacity models are suitable for large-scale production. This machine combines practicality and flexibility, providing a high-speed solution for uniform fragrance mixing.

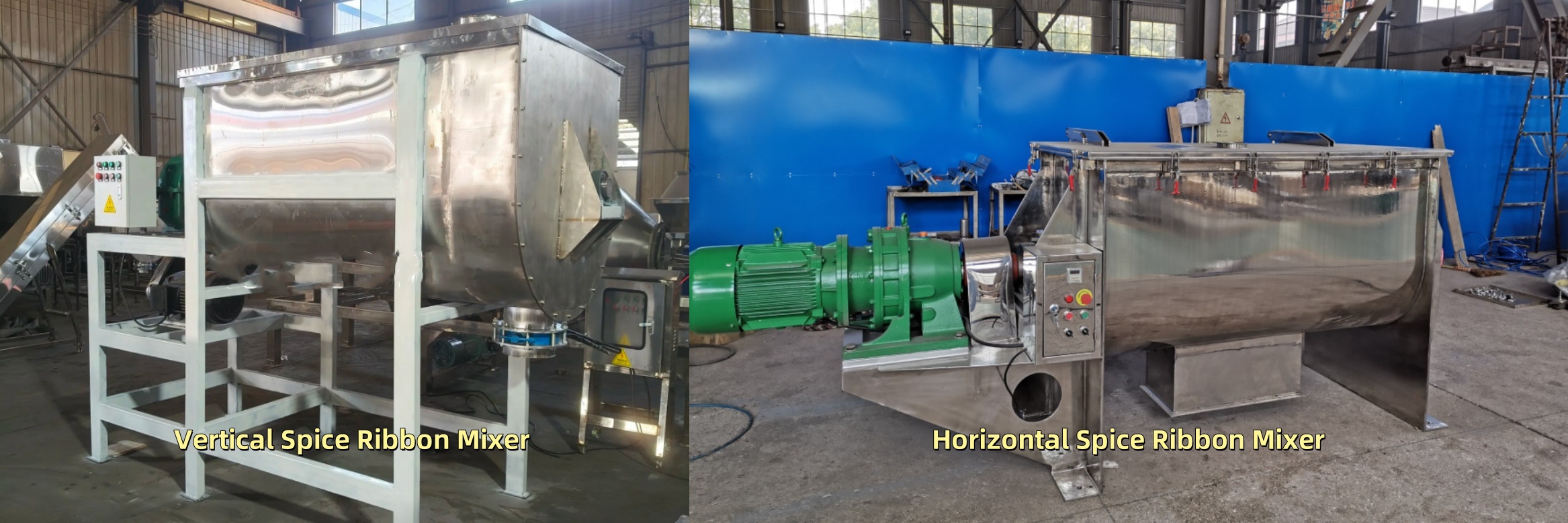

We manufacture both horizontal and vertical Spices ribbon mixers to meet our customers' production needs. Both are made of 304/316L stainless steel, meet food-grade standards, support solid-liquid mixing and customized heating and cooling, and are suitable for large-scale production of multi-component spices. Select the appropriate model to meet different production capacity requirements.

Vertical Spice Ribbon Mixer: Featuring a vertical barrel design, the mixer occupies a compact footprint and is ideal for limited workshop space. Its ribbon mixing element rotates vertically, mixing materials by tumbling upwards and downwards. Its single-shot mixing capacity is typically under 50L, making it ideal for small-batch processing needs in home workshops and small restaurant kitchens.

Horizontal Spice Ribbon Mixer: With a horizontal U-shaped barrel as its core structure, the ribbon mixing element is arranged horizontally, supporting double-layered ribbon counter-current mixing for more uniform mixing. Its single-shot mixing capacity ranges from 50L to 2000L, and it can handle liquid, viscous, or agglomerated spices. It is suitable for large-scale production in medium-sized seasoning factories and large-scale food processing plants.

The spices Ribbon Mixer offers numerous advantages, precisely tailored to the needs of spice processing. It's highly hygienic, easy to clean, and leaves no residue, preventing spice odor transfer or contamination. It also provides excellent mixing performance, evenly blending powders, granules, and lightly oily spices without clumping.

Gentle mixing action: Ribbon blenders provide gentle mixing action, which is very important when blending fine spices as they should not be over-mixed to maintain their quality.

Customizable design: Ribbon blenders can be customized to the specific requirements of blended spices. The size, shape, and speed of the ribbon can be adjusted to achieve the desired blending effect.

Sanitary design: Many ribbon blenders are designed with easy cleaning in mind, making them suitable for food processing applications such as blending spices.

Batch or continuous blending: Ribbon blenders can be used for both batch and continuous blending operations, depending on the production requirements.

Blending uniformity: Ribbon blenders provide excellent blending uniformity, ensuring that all spices are evenly distributed in the blend.

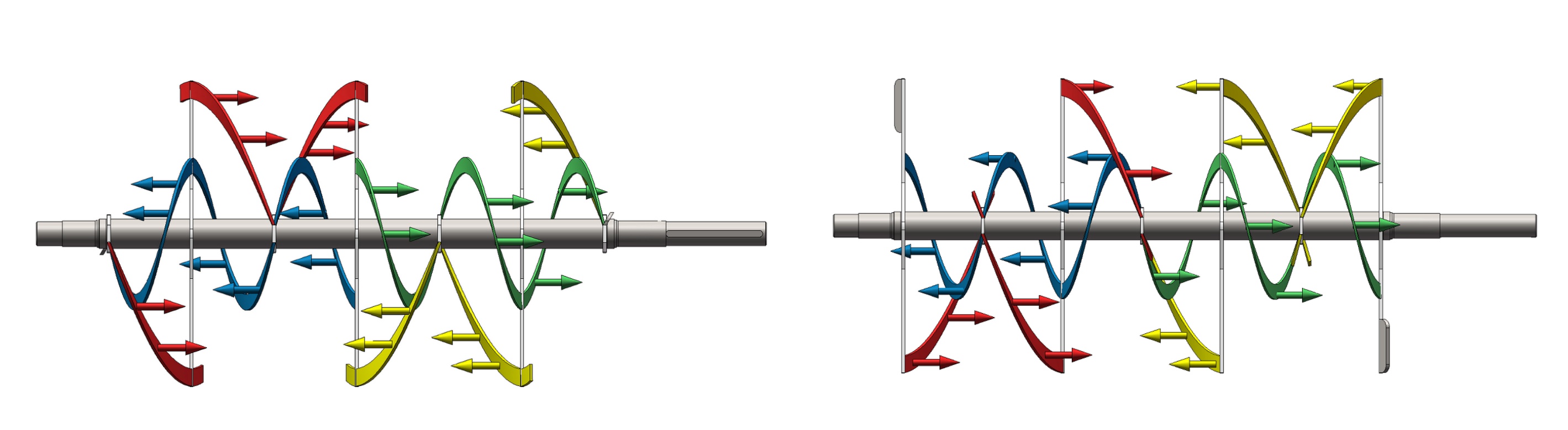

When a spices ribbon mixer is in operation, a motor drives the agitator shaft, driving the ribbon agitator to perform a spiral, circulating agitation within the drum. Its unique double-layered ribbon design allows the outer ribbon to push the material from the ends toward the center, while the inner ribbon rotates the material from the center toward the ends, creating efficient convection mixing. This structure enables rapid and uniform mixing of various materials, including spice powders, granules, and liquids, ensuring seamless mixing. During mixing, the speed can be adjusted to control the mixing intensity as needed.

The mixing time for a single spice ribbon mixer cycle varies depending on the spice type, mixing amount, and desired uniformity, typically ranging from 5-20 minutes. When mixing pure powdered spices with fine, non-sticky particles, 5-10 minutes is sufficient to achieve over 99% uniformity. When mixing a mixture of granular and powdered spices, due to the slightly different specific gravities, the mixing time may need to be extended to 10-15 minutes to ensure thorough blending of the two materials. When processing spices containing a small amount of oil, which are prone to slight clumping, the mixing time may need to be extended to 15-20 minutes. Adjusting the ribbon speed can aid dispersion and prevent uneven mixing. In practice, the mixing time can be fine-tuned based on sample test results and production needs to balance efficiency and mixing quality.

The spice ribbon mixer primarily utilizes the counter-rotating motion of a double-layered ribbon to create two core mixing modes, creating a "sides - center - sides" cycle. This ensures efficient mixing while also adapting to the processing needs of both conventional and specialized spices.

From the sides to the center: The outer ribbon features a specific spiral angle. During operation, it continuously pushes spices from the sides of the inner wall toward the center, making it particularly suitable for processing materials with initially uneven distribution.

From the center to the sides: The inner ribbon rotates in the opposite direction from the outer ribbon, pushing spices from the center back to the sides, creating a countercurrent circulation with the outer ribbon. This configuration allows repeated cross-contamination of the material within the barrel, effectively breaking up clumps and promoting uniform mixing of solids and liquids for sticky, clumped, or liquid-containing spices.

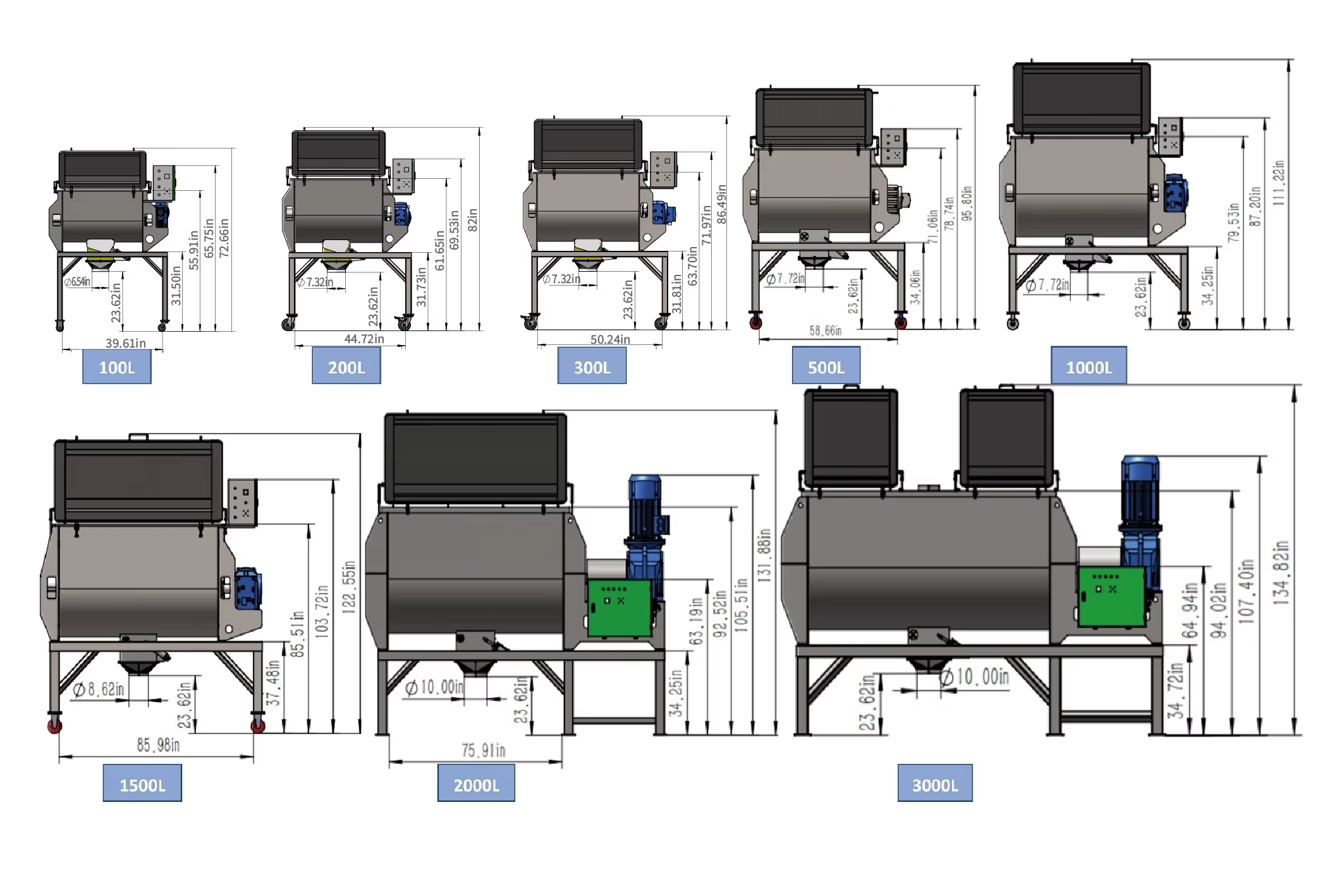

Spices ribbon mixers are typically sized according to production capacity, adapting to different scenarios. Small models can mix 30-60kg at a time; medium-sized models can handle 100-300kg, suitable for central catering kitchens; and large models can mix 400-1200kg at a time, meeting the needs of mass production in food factories.

Laboratory or pilot scale: Ribbon mixers designed for laboratory or pilot-scale operations typically have a smaller capacity ranging from around 1 liter to 20 liters. These smaller mixers are used for research, development, and small-scale testing of spice blends.

Small to medium scale production: For small to medium-scale spice production, ribbon mixers with capacities ranging from 50 liters to 500 liters are commonly used. These mixers are suitable for producing moderate quantities of spice blends efficiently.

Medium to large scale production: In larger spice production facilities, ribbon mixers with capacities between 500 liters to 2000 liters or more are often utilized. These mixers can handle higher volumes of spices and are suitable for continuous or batch mixing operations.

Custom sizes: Depending on the specific needs of the spice processing industry, ribbon mixers can be custom-built to accommodate even larger capacities, exceeding 2000 liters, to meet the demands of high-volume spice blending operations.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The Spices ribbon mixer is suitable for most solid spices, especially three main types: pure powdered spices, granular and powdered blends, and light, oily spices.

For sticky, clumping powdered spices:for damp, clumping cumin powder, brown sugar seasoning powder, and sesame powder with a small amount of oil, this machine uses powerful convection mixing with a double-screw ribbon to break up lumps and achieve uniform mixing, preventing localized sticking.

For solid-liquid-solid paste-type mixed spices:for example, pepper powder that requires the addition of cooking oil, star anise powder for syrup, and compound spices for sauces, liquid can be injected through a customizable nozzle. Combined with the ribbon's stirring mechanism, the solid and liquid are fully integrated, forming a homogeneous paste or moist powder.

For conventional powdered and granular spices:for dry chili powder, peppercorns, and cinnamon bark, even with significant differences in fluidity, the forward push and reverse tumbling motion of the ribbon ensures effective mixing, making it suitable for most basic spice processing needs.

The Spices ribbon mixer has a wide range of applications. Family businesses and individual spice shops use it to mix small batches of spices like cumin powder and Sichuan peppercorns to meet daily sales needs. Restaurant chain central kitchens use it to batch mix custom seasoning powders. Food processing plants use it to blend granules and powders, providing a homogenous blend for sauces, snacks, and prepared dishes.

Compound seasoning production: In the production of instant noodle seasoning, eight-treasure porridge ingredients, and pickling ingredients, various spices (such as salt, sugar, chili powder, and spices) must be uniformly mixed with the food base. The ribbon mixer's multi-directional motion allows the material to flow in three dimensions, avoiding the gravity segregation caused by centrifugal force in traditional mixers and ensuring a consistent ratio of spice ingredients in every gram of product.

Functional food additive mixing: For example, when mixing nutritional enhancers such as bone meal, egg peel powder, and konjac flour with spices, it is important to maintain the active ingredients. The gentle mixing action of the ribbon mixer reduces frictional heat generation and prevents nutrient loss.

Fragrance powder blending: In the production of fragrance powders for products such as perfumes and scented candles, natural and synthetic flavors must be uniformly mixed. The ribbon mixer's multi-directional stirring structure ensures that the tiny spice particles are fully contacted, preventing clumping and ensuring consistent fragrance release.

Mixing of pharmaceutical flavoring intermediates: In the pharmaceutical industry, some drugs require flavoring to improve their taste. Ribbon mixers can be used to evenly blend pharmaceutical flavorings (such as menthol and limonene) with drug powders, ensuring that the flavoring content in each tablet meets the specified standards.

Pretreatment of chemical flavoring raw materials: In the production of synthetic flavorings, various chemical raw materials must be mixed with flavor precursors. The sealed design of the ribbon mixer prevents the escape of volatile flavoring components while accelerating the contact of reactants through multi-directional movement.

The spices ribbon mixer can be integrated with packaging machines, screeners, and conveyors to create an automated spice processing line, meeting the needs of the entire process from mixing to finished product.

Packaging machine: After mixing, the spices can be directly conveyed to an automatic packaging machine via a pipe or discharge device for quantitative filling and sealing. This combination is suitable for bagging or canning powdered and granular spices, reducing human contact, improving hygiene standards, and packaging efficiency.

Screening machine: A vibrating screener can be connected before or after mixing to remove lumps, impurities, or particles that do not meet particle size requirements.

Conveyor: Screw conveyors and bucket elevators can automatically transport raw materials to the mixer inlet or transport mixed spices to the next process.

The Dahan Vibration Machinery spices ribbon mixer starts at $1,000 and is suitable for spice processing of varying scales. Because the equipment can be customized to meet all dimensions, pricing should be tailored to specific needs. Upgrading to 316L stainless steel, adding rollers with brakes for improved maneuverability, or customizing a spray system or variable frequency speed control system will increase the price accordingly. For medium and large models with customized features like automatic loading and sealing optimization, pricing will be further adjusted based on configuration differences. A detailed quote will be issued based on specific needs.

DaHan Machinery's Spices ribbon mixer is made of 304/316L stainless steel, with a mirror-polished inner wall eliminating unsanitary corners and preventing spice cross-contamination and residue. It supports full customization, allowing for the addition of heating/cooling functions as needed, and is suitable for mixing heat-sensitive and highly corrosive spices. Single/double ribbon models cover volumes from 50L to 5m³. We have a complete R&D, production, and service system, using high-quality materials for core components, which undergo rigorous quality inspection to ensure stability and durability. We provide pre-sales selection consultation, in-sales debugging, and after-sales spare parts supply. Our products have served over a thousand spice and compound seasoning companies, earning a reputation for high uniformity, low consumption, and high efficiency, making us a reliable partner for customized mixing equipment in the spice industry.

The spices ribbon mixer, with its food-grade stainless steel construction, flexible customization capabilities, and versatile adaptability, has become a core piece of equipment in the spice processing industry. It can meet the small-batch mixing needs of home workshops, while also supporting large-scale production in food factories by integrating with screening machines, conveyors, and packaging machines. From mixing efficiency and hygiene standards to mobility, it fully meets the requirements of spice processing.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.