Stationary Small Vertical Feed Mixer is a stationary industrial equipment designed for small to medium batch feed mixing, featuring a vertical mixing structure at its core. The equipment can mix 0.05-2m³ per cycle, meeting single-batch production needs ranging from tens of kilograms to 2 tons, with a mixing time of only 4-10 minutes, precisely matching the rhythm of small-batch, intermittent production. Parts in contact with materials can be customized with 304 or 316L stainless steel. Furthermore, we can customize the mixing structure, add spray devices or CIP cleaning systems based on the customer's site dimensions, material characteristics, and functional requirements. We can also modify the power supply and the position and shape of the inlet and outlet to suit different industry clients.

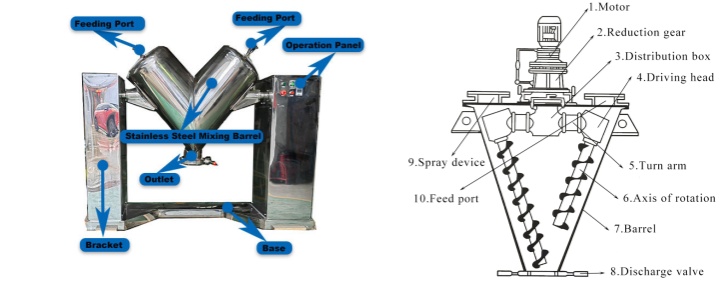

Based on customer production needs and site conditions, we primarily offer two types of stationary small vertical feed mixers: V-type and conical spiral type. Both types support customization with 304/316 stainless steel to meet the mixing needs of different scenarios.

V-type Stationary Small Vertical Feed Mixer: Centered on a V-shaped rotating cylinder, it is fixed with a vertical support and is primarily designed for intermittent operation. The cylinder's rotation causes materials to alternately separate and combine within the V-shaped space, achieving mixing through gravity diffusion and convection. This results in gentle mixing and good particle integrity.

Conical Stationary Small Vertical Feed Mixer: Utilizing a conical container with a vertical single/double/triple helical mixing structure, it is vertically fixed. The helical structure lifts the material, and the guide plates direct radial convection, forming a compound circulation mixing effect. It can handle materials with significant differences in specific gravity and particle size.

The Stationary Small Vertical Feed Mixer, with its compact design, high-speed mixing capability, and flexible adaptability, demonstrates significant advantages in scenarios with limited space and small-scale production.

Vertical design saves space: The vertical structure reduces the equipment's footprint to only 1/3 of a traditional horizontal mixer, making it particularly suitable for urban factories, laboratories, or indoor production environments.

Modular Configuration for Flexible Application: Supports modular expansion with heating jackets, cooling devices, etc., allowing for functional configuration adjustments based on process requirements.

Three-Dimensional Motion for Uniform Mixing: The propeller blades drive the material in a composite motion path of vertical lifting, radial diffusion, and central projection, ensuring that every particle participates in the mixing process.

Adaptable to Multiple Material Forms: Can handle powders, granules, viscous fluids, and even pastes. It is particularly effective for mixing heat-sensitive materials and fragile particles, avoiding overheating or crushing issues.

The main structure of the Stationary Small Vertical Feed Mixer consists of a stainless steel cylinder, a spiral agitator, a drive system, and inlet/outlet ports. Its vertical design reduces the equipment's footprint to only 1/3 that of a traditional horizontal mixer.

Agitator: Dual propeller blades fit tightly against the inner wall of the cylinder, driving the material circulation and mixing via the main shaft. Some models are equipped with adjustable-angle blades, capable of handling various raw materials such as particles, crushed materials, and powders.

Drive System: Employs direct worm gear drive or a motor-reducer combination, with power ranging from 250W to 1.1kW, supporting manual, pneumatic, or electric control to meet various automation needs.

Inlet/Outlet: The top inlet is designed in a funnel shape to ensure smooth material flow; the bottom outlet is equipped with a "flower-shaped" offset valve or butterfly valve to reduce residue and prevent blockage. Some models support heating jackets or cooling devices, achieving temperature control through circulating heat transfer oil or hot water.

The Stationary Small Vertical Feed Mixer completes material mixing through an intermittent process of feeding-forced mixing-discharging. During operation, material is fed into the vertical cylinder through the top inlet. After starting the equipment, the machine uses the rotation of the cylinder to alternately separate and combine the material, achieving homogenization through gravity diffusion and convection. The conical model uses a rotating vertical spiral stirring shaft to lift the material from the bottom, which is then guided by baffles to diffuse outwards, forming vertical circulation and radial convection.

The stationary small vertical feed mixer, with its compact footprint and adaptability to small to medium production capacity, is widely used in various industries.

Feed Processing: Suitable for small and medium-sized farms and feed processing plants, used for mixing premixes for pigs and chickens, and concentrates for cattle and sheep, processing batches of corn flour, soybean meal, and additives in batches of 0.05-2m³.

Food Processing: Suitable for food workshops and small food factories, mixing flour, starch, grain powder, and seasonings. 304 stainless steel models meet hygiene requirements.

Chemical and Building Materials: Used for small-batch ingredient mixing in laboratories, mixing plastic additives and paint powders in small chemical plants, and mixing putty powder and mortar additives in building materials workshops.

Laboratory R&D: Small 10-20L units are commonly used for new material formulation experiments and pharmaceutical raw material premixing, etc. Their precise control capabilities ensure the reliability of experimental data.

V-type Stationary Small Vertical Feed Mixer

| Type | Swept Volume(L) | Total Volume(L) | Mixing Power(kw) |

| VH-2 | 0.8 | 2 | 0.04 |

| VH-5 | 2 | 5 | 0.55 |

| VH-8 | 3.2 | 8 | 0.55 |

| VH-10 | 4 | 10 | 0.55 |

Conical Stationary Small Vertical Feed Mixer

| Model | Total volume(L) | Capacity(kg) | Mixing time(Minutes) | Power(kw) | Total height(m) | Weight(kg) | |

| CF-DSH-1 | 1000 | 400-600 | 5-10 | 4 | 2775 | 1200 | |

| CF-DSH-2 | 2000 | 800-1200 | 5-10 | 5.5 | 3424 | 1500 | |

| CF-DSH-6 | 6000 | 2400-3600 | 5-10 | 15 | 4960 | 3500 | |

| CF-DSH-8 | 8000 | 3200-4800 | 5-10 | 18.5 | 5378 | 4000 | |

| CF-DSH-10 | 10000 | 4000-6000 | 5-10 | 18.5 | 5678 | 4300 | |

| CF-DSH-12 | 12000 | 4800-7200 | 5-10 | 22 | 6015 | 4500 | |

| CF-DSH-15 | 15000 | 6000-9000 | 5-10 | 30 | 6650 | 5000 | |

| CF-DSH-20 | 20000 | 8000-12000 | 5-10 | 37 | 7176 | 6000 |

Stationary Small Vertical Feed Mixers and stationary small horizontal feed mixers differ significantly in structure, mixing effect, applicable scenarios, energy consumption, and cost.

Structure and Space Occupancy: Vertical mixers use a vertical stirring shaft as their core, and the container is mostly conical or cylindrical. They are compact and occupy little space, making them suitable for production environments with limited space. Horizontal mixers have a horizontal stirring shaft, and the container is a horizontal cylinder or U-shaped trough. They are relatively large and occupy a larger area, and are mostly used in feed mills and other scenarios requiring large-scale continuous production.

Mixing Effect and Uniformity: Vertical mixers achieve convection circulation mixing through vertical stirring and material gravity. The mixing cycle is shorter; for example, 3.2L of material can be mixed within 6 minutes, meeting simple mixing needs. Horizontal mixers rely on the rotation of the stirring shaft to drive the material horizontally for mixing, resulting in higher uniformity, especially suitable for materials that are difficult to disperse.

Applicable Scenarios and Material Characteristics: Vertical mixers are suitable for free-flowing powders, granules, or liquids, such as feed premixing and mortar mixing. They are mainly used in small-batch production, budget-constrained scenarios, or confined spaces. Horizontal mixers, on the other hand, excel at handling high-viscosity materials and materials requiring high-uniformity mixing. They can handle the mixing of powders/granules with liquids/pastes and are suitable for large-scale continuous production.

Energy Consumption and Cost: Vertical mixers have lower energy consumption, consuming less than 0.2 kWh per mixing cycle, and have relatively low initial investment, making them suitable for lightweight production with limited budgets. Horizontal mixers have higher power and energy consumption, but their higher mixing efficiency may result in better energy consumption per unit output when handling large volumes of materials. Their higher initial investment makes them suitable for large-scale production.

Choosing the right Stationary Small Vertical Feed Mixer requires comprehensive consideration of four aspects: material characteristics, production capacity requirements, site conditions, and functional compatibility. First, determine the material type: for free-flowing powders/granules, choose the basic model; for solid-liquid mixing, choose a model with a spray device. For food/pharmaceutical applications, prioritize 304/316L stainless steel to ensure hygiene and corrosion resistance. Second, match the production capacity: select the volume based on the mixing volume per batch and daily output. Small-batch laboratories use 5-50L models, while small and medium-sized farms/workshops choose 50-300L models to avoid wasted or insufficient capacity. Third, consider the site space: measure the length, width, and height of the installation area, prioritizing compact models that have a small footprint and meet site size limitations. Finally, balance function and cost: for high uniformity, choose a conical spiral type; for simplicity and economy, choose a V-shaped rotary type, ensuring easy operation and maintenance, and adapting to your production process and budget.

Dahan Machinery is a source manufacturer specializing in the R&D and production of Stationary Small Vertical Feed Mixers, with over ten years of experience in the industry. Our product range covers a full range of models from 0.05-2m³, including V-type and conical spiral mixers. Custom materials include carbon steel, 304 stainless steel, and 316L stainless steel. Features such as spraying and CIP cleaning can be added, making them suitable for various applications in feed, food, and chemical industries. Production utilizes precision machining equipment, and core components are sourced from renowned brands, ensuring stable and durable equipment. We provide pre-sales selection guidance, customized drawings, on-site commissioning, after-sales service, and spare parts support. Machine dimensions and mixing structures can be customized to meet specific needs. Our high-performance products and attentive service have earned market recognition, providing customers with high-speed, adaptable mixing solutions.

Stationary Small Vertical Feed Mixers, with their compact size and high power output, are becoming indispensable mixing equipment in modern industry. For businesses or laboratories with limited space and small production scales, stationary small vertical feed mixers are an ideal choice for solving mixing challenges due to their compact design, high-speed mixing capacity, and flexible adaptability.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.