Cattle feed pellet machine is a kind of equipment specially used for processing cattle feed. It can process, mix, press and shape the raw materials into high-quality, uniform-sized pellet feed. Cattle for feed pellet machine plays an important role in the livestock breeding industry and provides an efficient and sustainable feed processing solution.

As a source manufacturer, we can customize equipment according to customer needs and sell different types of pellet machines for customers to use.

Ring die pellet machine: Ring die pellet machine is currently a widely used cattle feed pellet machine. Its ring die structure design makes the feed evenly stressed during the pressing process, and the pellet feed produced is of stable quality, smooth appearance and moderate hardness. Ring die pellet machine is suitable for large-scale cattle farms with high production efficiency and an hourly output of several tons.

Flat die pellet machine: The working principle of the flat die pellet machine is similar to that of the ring die pellet machine, but its mold is a flat structure. The flat die pellet machine has the advantages of simple structure, convenient operation and relatively low price, and is suitable for small cattle farms or family farmers.

The working principle of cattle for feed pellet machine is based on the process of mechanical pressing and heat treatment. First, the raw feed is put into the pellet machine through the feeding system. Then, the raw material is squeezed by the press and formed by the die in the pellet machine to form pellet feed with moderate density and uniform size. During the pressing process, an appropriate amount of water or steam is usually added to improve the forming and stability of the pellets. Finally, the finished pellet feed is discharged through the discharging system.

Cattle for feed pellet machine usually consists of the following main components: feeding system, pressing system, die, discharging system and electronic control system. The feeding system is used to transport the raw feed into the pellet machine, the pressing system presses the raw material into pellet feed through mechanical pressure, the mold is used to shape the shape and size of the pellets, the discharging system discharges the finished pellets, and the electronic control system controls the entire working process.

The cattle for feed pellet machine has the following characteristics and advantages:

Efficient production: The cattle for feed pellet machine can efficiently process the raw materials into pellet feed, improve production efficiency and output.

Optimize feed formula: By adjusting the raw material ratio and processing technology, a balanced and nutritious feed can be produced to meet the growth and development needs of cattle.

Improve feed utilization: The pellet feed has a uniform particle size and high solubility, which is easy to digest and absorb, improving feed utilization and animal production performance.

Convenient storage and transportation: The pellet feed has a consistent shape and size, which is easy to store and transport, reducing feed waste and loss.

Environmental protection and energy saving: The cattle for feed pellet machine adopts mechanical pressing processing, without the need to add chemicals, reducing environmental pollution, and can also use the heat generated during the pressing process to reduce energy consumption.

Cattle for feed pellet machine is suitable for processing all kinds of cattle feed, including cattle grain, forage, straw, corn, soybean residue, fish meal, etc. It can meet the feeding needs of cattle at different stages, such as feed processing in the juvenile period, growth period and mature period.

Energy feed pellets: mainly based on carbohydrate-rich raw materials, such as corn, wheat, barley, sorghum and other grains. These grains are crushed and processed into pellet feed, which can provide rich energy for cattle.

Protein feed pellets: usually soybean meal, cottonseed meal, rapeseed meal, fish meal, meat and bone meal, etc. are used as the main raw materials, and pellets are made through a pellet machine.

Roughage pellets: various hay powders (such as alfalfa powder, sheep grass powder), straw powder (such as corn straw powder, wheat straw powder), etc. are used as the main raw materials to make suitable feed pellets for cattle.

Complete feed pellets: according to the nutritional needs of cattle at different growth stages and production purposes, energy feed, protein feed, roughage, minerals, vitamins and other additives are mixed in scientific proportions and processed through cattle feed pellet machines.

| Pellet Type |

Diameter Range (mm) |

Target Animal/Stage | Key Technical Parameters | Feeding Benefits |

| Micro Pellets | 2-3 | Newborn calf milk replacer |

Die compression ratio 1:5-1:6 Pelletizing temp ≤60℃ |

Prevents choking (palatability +40%) Digestibility improved 25-30% |

| Small Pellets | 3-5 | Weaning calves (3-6 months) |

5-8% molasses added Hardness 50-60N Crude protein ≥18% Starch gelatinization 45-50% |

Facilitates transitional feeding Reduces digestive stress |

| Standard Pellets | 6-8 |

Growing cattle (7-18 months) Gestating cows |

Compression ratio 1:8-1:10 Steam conditioning 75-85℃ |

Feed conversion ratio 4.2-4.5:1 Daily gain 1.3-1.5kg |

| Large Pellets | 8-10 | Finishing cattle |

Deep-hole die (L/D ratio 1:12) 3-5% fat coating |

Feed intake +15-20% Marbling score +0.5 grade |

| Coarse Pellets | 10-12 |

Straw processing TMR base |

Pre-conditioning moisture 18-20% Double pelleting |

Ruminating time +30% NDF digestibility +8-10% |

When choosing a suitable machine, we can combine the following points for selection.

Small (100-300kg/h): suitable for farms with less than 50 heads, with a power configuration of 7.5-15kW motor.

Medium (500-1000kg/h): suitable for farms with 50-200 heads, with a power configuration of 22-55kW motor.

Large (1-5t/h): suitable for farms with more than 200 heads, with a power configuration of more than 75kw.

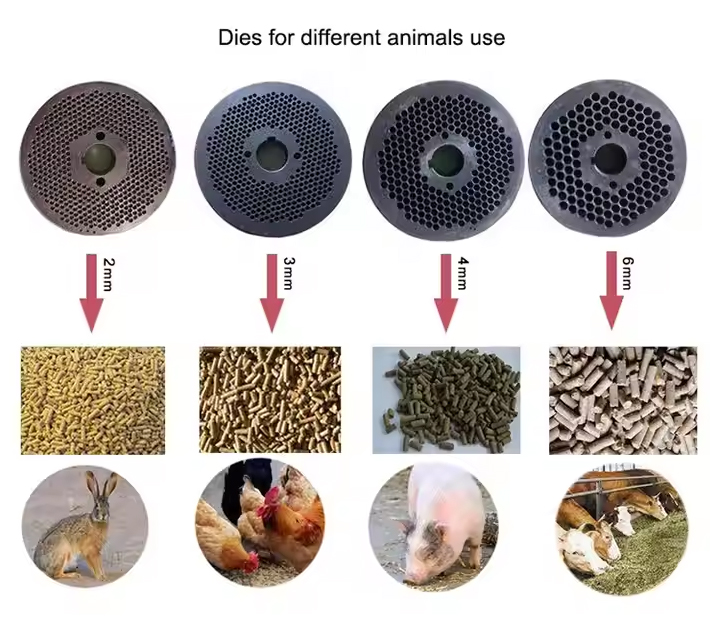

Aperture selection: 8-10mm for fattening cattle, 4-6mm for calves

Material: alloy steel mold is preferred, with a service life of up to 500-800 hours

When using cattle for feed pellet machine, you need to pay attention to the following matters:

Select the appropriate pellet machine model and specifications to adapt to the expected output and feed type.

Properly crush and mix the raw materials to ensure the normal operation of the pellet machine and the quality of the pellets.

Clean and maintain the pellet machine regularly to ensure the normal operation of the equipment and extend its service life.

According to the characteristics of pellet feed and animal needs, reasonably adjust the feed formula and pellet size.

Cattle for feed pellet machine is an indispensable equipment in modern dairy farming. It can improve feed utilization, improve feed hygiene, improve dairy cow production performance, and ultimately improve farming benefits. Choosing a suitable cattle feed pellet machine and performing reasonable maintenance can effectively reduce breeding costs, improve economic benefits, and provide strong guarantees for the development of dairy farming.

The price of cattle feed pellet machine varies depending on equipment specifications, capacity configuration and functional characteristics. Small equipment is suitable for family farms or small-scale farms, and the price is relatively affordable; medium-sized equipment is aimed at professional farms, with significant improvements in capacity and durability, and the price is moderate; large-scale industrial equipment has automated control systems and high-yield advantages, suitable for large-scale breeding enterprises, and the price is higher. Factors such as equipment material, power configuration (electric or diesel), and mold specifications will affect the final quotation. Our customers can customize on demand, and some suppliers will also provide flexible purchase plans such as installment payments.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.