Food grade for stainless steel paddle mixer made of high-quality 304/316L stainless steel, it is resistant to acids and alkalis, corrosion-resistant, and mirror-polished to ensure a contamination-free mixing process and easy cleaning. We can customize it according to your specific needs; the mixing capacity and time are flexibly adjustable, with a mixing range from 50 liters to 5000 liters, meeting various needs from pilot production to large-scale production. The mixing time is fast and controllable, achieving uniform mixing within 3-15 minutes. The paddle design ensures 360° tumbling of materials, enabling high-precision mixing of powders, liquids, and sauces.

The stainless steel material is not only durable but also effectively prevents the precipitation of metal ions, ensuring product safety. Seamless welding and quick-release design further simplify the cleaning process and reduce the risk of cross-contamination. Whether it's dairy products, condiments, or pharmaceutical raw materials, we can recommend the appropriate model and provide a one-stop solution based on your specific needs!

Food-grade stainless steel paddle mixers are mainly divided into two types based on their material: 304 stainless steel paddle mixers and 316 stainless steel paddle mixers. These differ in performance, applicable scenarios, and cost.

304 Food Grade Stainless Steel Paddle Mixer: Utilizing a classic formula of 18% chromium and 8% nickel, it boasts excellent corrosion resistance, oxidation resistance, and mirror-polishing properties. With moderate cost and easy cleaning, it is widely applicable to general food processing scenarios, such as mixing dry powders (flour, powdered sugar), low-acid sauces (peanut butter), and dairy products (milk powder), where high corrosiveness is not required. It is the top choice for cost-effectiveness.

316 Food Grade Stainless Steel Paddle Mixer: By adding 2%-3% molybdenum, its resistance to chloride ions and acid corrosion is significantly improved. Specifically designed for high-salt, high-acid, or highly corrosive materials (such as seafood seasonings, acidic jams, and pharmaceutical excipients), it meets pharmaceutical-grade standards, effectively reducing the risk of metal contamination and extending equipment life. Suitable for high-end food and pharmaceutical production fields with stringent safety requirements.

The body and all parts in contact with materials are made of stainless steel, meeting food hygiene standards. Utilizing a forced convection design, it quickly and evenly mixes flour, seasonings, nutritional powders, and other materials.

Corrosion and contamination resistant: Made of 304/316L stainless steel. 304 is suitable for general food environments, while 316L, due to its molybdenum content, is resistant to acids, alkalis, and chloride ion corrosion, allowing for long-term contact with high-salt and acidic materials without the release of harmful substances, ensuring product safety.

No metal ion risk: The dense and smooth surface of stainless steel avoids rust or heavy metal contamination that can occur with traditional materials.

Uniform and thorough mixing: The optimized paddle structure (flat paddle, angled paddle, turbine paddle) achieves rapid and uniform mixing of powders, liquids, sauces, and other materials through 360° tumbling and mixing, resulting in short mixing times.

Flexible capacity customization: Supports customized mixing capacity to meet different needs from small-scale R&D to large-scale mass production, compatible with multiple industries including dairy products, seasonings, meat products, and pharmaceutical raw materials. Seamless welding process: The inner wall of the equipment adopts seamless welding technology to eliminate unsanitary dead corners and avoid the growth of bacteria from material residue.

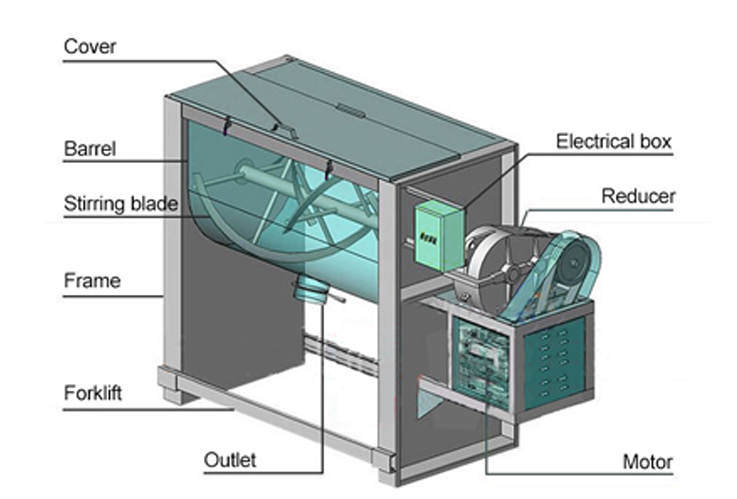

Food grade stainless steel paddle mixers usually consist of mixing barrels, motors, transmissions, paddles and other components. The mixing barrel is used to contain food ingredients. The motor provides power to drive the paddles to rotate. The transmission device transmits the power of the motor to the paddles, and the paddles are responsible for mixing the food ingredients.

Mixing tank: food grade stainless steel 304 or 316L, the structure can be designed into round, square, conical, etc. according to needs.

Paddle: food grade stainless steel material, various shapes (such as flat paddle, inclined paddle, frame, etc.), can be selected according to material characteristics.

Transmission system: The motor is used to provide power to drive the stirring shaft to rotate. Reducer, reduce the motor speed and increase the torque.

Support frame: Support the mixing tank, transmission system and other components to keep the equipment stable.

Base: Fix the equipment to prevent the equipment from moving.

The food-grade stainless steel paddle mixer uniformly mixes food ingredients through the rotation of the paddles. When food ingredients are placed into the mixer, the paddles begin to rotate, pushing the ingredients to all corners of the mixing chamber to ensure that each part is fully mixed. This efficient mixing method can improve production efficiency, reduce mixing time, and reduce production costs.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Food grade for stainless steel paddle mixer thanks to their food-grade materials and rapid mixing performance, are widely used in various sub-sectors of food production. They can meet the mixing needs of different food production processes and are core equipment for ensuring uniform food quality and high production efficiency.

Baking industry: Homogenizing flour with yeast, improvers, sugar, and other auxiliary ingredients, suitable for bread, cake, and biscuit production.

Seasoning industry: Proportional mixing of spice powders, sauce powders, and compound seasonings to ensure uniform flavor.

Nutritional food industry: Precise mixing of protein powder, meal replacement powder, cereal powder, vitamins, minerals, and other ingredients.

Snack food industry: Mixing nut powder, fruit and vegetable powder, and puffed food ingredients, suitable for snack processing techniques.

Pet food industry: Premixing pet dry food ingredients and nutritional additives to meet pet food hygiene standards.

Food grade stainless steel paddle mixer can select the appropriate paddle type according to the specific application scenario, so as to achieve efficient mixing of various food raw materials.

Powder and powder mixing: such as flour, milk powder, powdered sugar, spices, etc.

Liquid and liquid mixing: such as beverages, soy sauce, vinegar, cooking oil, etc.

Solid and liquid mixing: such as juice and pulp, syrup and additives, suspension of solid particles in liquid, etc.

Paste material mixing: such as dough, fillings, jam, etc.

We provide diverse mixing solutions for clients across various industries. These solutions all utilize food-grade materials to ensure safety, and are customized to suit specific processes, helping clients improve quality and efficiency, earning widespread recognition across industries.

Dairy Industry: This industry needed to address the challenge of uneven mixing of high-value nutrients while strictly meeting aseptic standards. To address this, the company customized a 1000L capacity 316L stainless steel paddle mixer with a double-layer paddle design and a CIP online cleaning system. By optimizing paddle speed and mixing time, the segregation rate of milk powder and micronutrients was reduced to ≤0.5%, significantly improving mixing uniformity. The 316L material, after being sterilized at 121℃, showed no metal leaching, fully complying with EU infant food regulations.

Condiment Industry: This industry needed to solve the problems of uneven mixing of high-viscosity materials and inconsistent flavor caused by spice sedimentation. A company customized a 2000L capacity 304 stainless steel paddle mixer, employing a slanted paddle structure and variable frequency speed control technology, adaptable to material viscosities ranging from 5000-50000 mPa·s. The slanted paddle design ensures thorough emulsification of butter and spices, with no stratification observed after 24 hours of settling, resulting in a 90% decrease in customer complaints. The variable frequency motor automatically adjusts its speed based on material viscosity, reducing energy consumption per batch by 18% compared to the original equipment.

In the pharmaceutical industry: To produce solid dosage forms with highly active drug components, GMP certification must be met, and metal contamination leading to drug efficacy loss must be avoided. A company customized a 500L capacity 316L stainless steel paddle mixer, featuring a closed design, vacuum degassing, and 316L material screens for impurity filtration. Third-party testing showed that the nickel release from the 316L material was <0.1μg/g, far below the pharmacopoeia standard; laser particle size analysis indicated that the mixing uniformity of the drug and excipients decreased from 8% to 3%.

When selecting a food-grade stainless steel paddle mixer, focus on the material and polishing process. Pay attention to hygienic designs such as a corner-free cavity and quick-release paddles to ensure you select a mixing device that is suitable for food production and combines safety and efficiency.

Material Compliance: Parts in contact with materials must be made of 304 or 316L food-grade stainless steel to ensure corrosion resistance, no heavy metal leaching, and a polished surface to prevent bacterial growth from material residue.

Mixing Performance Suitability: Select the paddle type based on material characteristics (such as powder particle size, flowability, and oil/water content), and confirm that the mixing uniformity and stirring speed are adjustable.

Hygienic Design Details: The equipment must have no hygienic dead corners, be equipped with quick-release paddles, rounded transition cavities, and sealed bearings for easy CIP/SIP cleaning; also consider capacity matching, selecting the single-batch mixing capacity or continuous processing capacity based on production scale.

The price of DaHan Machinery's food-grade stainless steel paddle mixer is influenced by multiple factors, with the basic model starting at $1200. Price differences primarily stem from equipment specifications and configurations. Small laboratory models are suitable for small-batch sample production and are affordably priced; medium to large production models (100-500L) have higher prices due to increased capacity. Material selection also affects pricing; 316L stainless steel models are more expensive than 304 stainless steel models and are suitable for highly corrosive materials. Furthermore, adding features such as variable frequency speed control, dustproof sealing, and automatic cleaning, or meeting GMP or FDA certification standards, will increase the price. Ultimately, the most cost-effective solution can be chosen based on production scale and process requirements.

Dahan Machinery has been deeply involved in the food equipment industry for over ten years. The core components of our equipment are all made of 304/316L food-grade stainless steel, mirror-polished to eliminate any unsanitary corners. We have a senior R&D team that can customize paddle structures, mixing speeds, and production capacities (5-500L) according to customer material characteristics (such as powders, granules, and liquids). We also support the addition of modules such as automatic feeding and CIP cleaning. Equipped with standardized production lines and strict quality control processes, we provide one-stop service from solution design and commissioning to maintenance. We have provided safe and efficient mixing solutions to thousands of companies in the baking, seasoning, and nutritional food industries.

In general, food grade stainless steel paddle mixers play an important role in the above application scenarios, providing efficient mixing solutions for production in different industries. Our Dahan manufacturer produces different types of paddle mixers that can meet any of your needs. The maximum one-time mixing volume is 3000kg. If you need this type of paddle mixer, you can click on the website page for consultation, and we will develop a detailed plan for you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.