Indonesian powder ribbon mixer is a device for mixing powdered raw materials. It usually consists of a spiral agitator and a mixing tank. The spiral agitator is used to evenly mix powdered raw materials of different particle sizes, densities and shapes to ensure product quality and uniformity. Powder ribbon mixers are widely used in food, chemical, pharmaceutical and other industries, and play an important role in the production process.

As a dedicated supplier of Indonesian powder ribbon mixers, our Indonesia Powder Ribbon Mixer not only meet the needs of local industries such as chemicals, building materials, and food, but can also be exported to any country in the world, breaking geographical restrictions. We understand the diverse production needs of individual customers and offer comprehensive customization services. We can adjust the direction and position of the discharge port based on production line layout to ensure optimal fit. We also recommend custom anti-sticking wall structures and drying components based on material moisture to prevent material agglomeration and ensure mixing efficiency and quality, providing global customers with solutions tailored to their specific production needs.

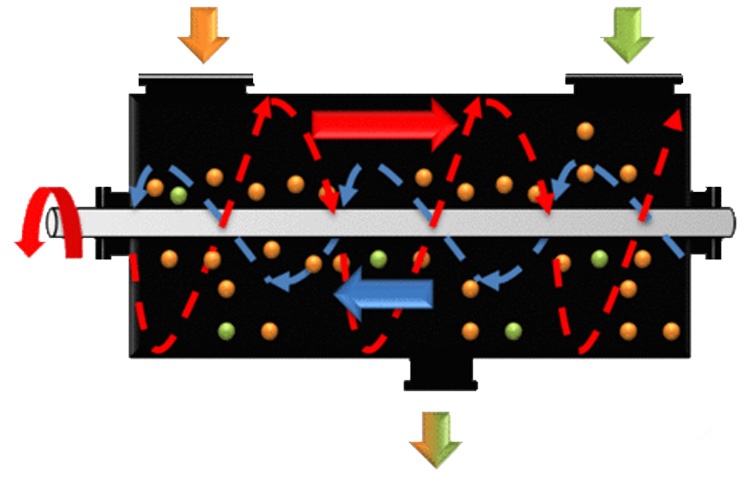

The Indonesia Powder Ribbon Mixer primarily consists of a horizontal drum, a twin-ribbon mixing system, a power drive, inlet and outlet mechanisms, and a control system. The discharge port location can be customized to meet specific requirements, and component design can be optimized based on material moisture content.

Main body: including mixing barrel and spiral agitator.

Motor and transmission device: drive the spiral agitator for mixing.

Feed port and discharge port: used to add raw materials and discharge the mixed products.

Control system: control the start and stop, speed and other parameters of the mixer.

Indonesia Powder Ribbon Mixer is based on a double spiral ribbon. Through the counter-rotating inner and outer spiral ribbons, the powder and particles in the cylinder are pushed from both ends to the center and vice versa. The shearing effect breaks up the agglomerated materials and quickly achieves uniform mixing.

Feeding: put the powdered raw materials to be mixed into the mixer through the feed port.

Stirring and mixing: start the motor to drive the spiral agitator to spirally stir and mix the raw materials.

Even mixing: the design of the spiral agitator ensures that the raw materials are evenly mixed in the mixing barrel to achieve the required uniformity.

Discharging: after mixing, the mixed product is discharged through the discharge port.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

Indonesia Powder Ribbon Mixer is widely used in the local chemical, building materials, food, and feed industries. It can mix chemical powders, building materials putty powders, food raw materials, and feed premixes, and is suitable for powders with different humidity levels.

Food processing industry: Indonesian powder ribbon mixer is used to mix various food raw materials, such as flour, seasonings, etc.

Chemical industry: Indonesian powder ribbon mixer is suitable for mixing powder raw materials such as chemicals and pigments.

Pharmaceutical industry: Indonesian powder ribbon mixer is used to mix pharmaceutical raw materials to ensure the quality of medicines.

Building materials industry: Indonesian powder ribbon mixer mixes cement, lime and other building materials.

The Indonesia Powder Ribbon Mixer is exportable globally, with customizable discharge port orientation and recommended models based on material moisture. Its twin-ribbon agitation ensures uniform mixing of powders and particles, making it suitable for a wide range of industries and applications, while ensuring both practicality and adaptability.

Efficient mixing: The spiral agitator design makes the mixing effect more uniform and improves production efficiency.

Wide applicability: Suitable for powder raw materials of various particle sizes, densities and shapes.

Easy operation: The equipment is simple to operate, easy to control and maintain.

Energy saving: Low energy consumption during mixing, saving energy costs.

Ensure product quality: Ensure the uniformity of mixed materials and improve product quality stability.

Sturdy and durable structure: Made of high-quality materials, the structure is sturdy and durable, and the service life is long.

As a highly efficient and versatile mixing equipment, Indonesia powder ribbon mixer plays an important role in food, chemical, pharmaceutical and other industries, providing a reliable mixing solution for the production process and improving production efficiency and product quality.

As a Powder Ribbon Mixer supplier deeply rooted in Indonesia, we specialize in twin-screw convection mixing equipment with a mixing uniformity exceeding 98%. It can handle both powder and granular materials and can be paired with a spray system to achieve powder-liquid mixing. We support full-dimensional customization, adjusting the discharge port position according to the production line, optimizing the anti-sticking wall design based on material moisture, and customizing explosion-proof and temperature control functions. Our equipment can be exported globally, solving mixing pain points and improving production efficiency for global customers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.