Protein Powder Ribbon Stainless Steel Mixer is a specialized mixing equipment developed for protein powder production and processing. Its core function is to solve the critical problem of achieving uniform mixing of protein raw materials and various additives. Designed specifically for the characteristics of protein powder materials and food production standards, it uses 304 or 316L stainless steel for parts in contact with materials, meeting hygiene standards while possessing excellent corrosion resistance and easy cleaning. The equipment supports full-process non-standard customization, with the drum volume customized according to the company's production scale and material characteristics. The mixing capacity ranges from 0.2-20m³ per cycle. The ribbon speed, discharge port position, and auxiliary devices can be adjusted as needed to adapt to different formulas and production line layouts. It can meet the production requirements of various protein powder categories, including fitness, infant, and senior products, and can seamlessly integrate with upstream and downstream equipment, providing companies with a fast, accurate, and safe mixing solution.

The Protein Powder Ribbon Stainless Steel Mixer boasts significant advantages in mixing efficiency, uniformity, hygiene and safety, equipment durability, and process adaptability, meeting the needs of protein powder mixing.

Hygiene and Safety Design: All contact parts are constructed from stainless steel. The 316L material, containing molybdenum, offers superior resistance to chloride corrosion, making it suitable for processes involving the addition of sensitive ingredients such as whey protein and probiotics.

Multi-Form Material Handling: The equipment can handle powders, granules, pastes, and viscous materials, supporting the uniform mixing of protein powder with ingredients such as chopped nuts and probiotics.

Temperature Control Function: Equipped with a jacketed heating/cooling system, supporting electric heating or heat transfer oil circulation, the temperature control accuracy is ±1℃, suitable for mixing processes of heat-sensitive ingredients.

Integrated Spraying Device: Equipped with a dedicated spraying module, it can uniformly spray liquid additives in a mist form, preventing localized clumping.

Production Line Compatibility: Seamlessly integrates with drying and packaging equipment, facilitating automated production and ensuring consistent product quality.

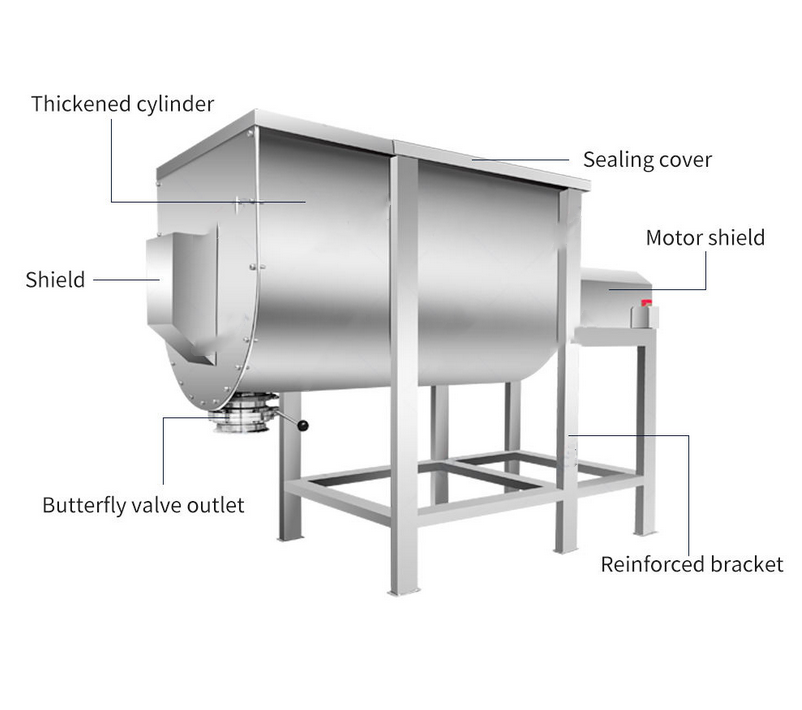

The Protein Powder Ribbon Stainless Steel Mixer achieves high-speed, uniform mixing through a precise structural design. Its core structure can be divided into several modules, which work together to ensure the stability and reliability of the mixing process.

U-shaped tank: Welded from 304/316L stainless steel, with a wall thickness of 3-8mm, and a large R100mm rounded bottom to eliminate material residue dead zones.

Double-layer helical ribbon structure: The outer helical ribbon has a pitch of 1/2 the container diameter and rotates clockwise, gathering material from both sides towards the center. The inner helical ribbon has a pitch 1.2 times that of the outer helical ribbon and rotates counterclockwise, pushing material from the center outwards.

Main shaft design: Utilizes a solid stainless steel shaft with a polished surface Ra≤0.8μm to reduce material adhesion.

Bottom discharge valve: A combination of a pneumatic butterfly valve and a conical discharge port, with a discharge angle ≥60°, ensuring the material slides down naturally.

Drive Motor: Utilizes a variable frequency speed-regulating motor with a power range covering 0.75kW to 30kW, supporting the power needs of 5-10000L volume equipment.

The Protein Powder Ribbon Stainless Steel Mixer achieves three-dimensional mixing through a double-layer counter-rotating spiral ribbon. The outer spiral ribbon rotates clockwise, pushing the material from both sides of the container towards the center, while the inner spiral ribbon rotates counter-clockwise, pushing the material from the center outwards, forming a bidirectional convection vortex. Simultaneously, the helical structure of the ribbon and main shaft drives the material to circulate and rise vertically, constructing a three-dimensional mixing trajectory. The stainless steel ribbon maintains a 2-5mm gap with the inner wall of the container, breaking up clumps through shear force. Combined with the U-shaped, dead-angle-free tank and bottom scraper, it ensures over 99% uniformity within 8-12 minutes.

We offer Protein Powder Ribbon Stainless Steel Mixers in various sizes to meet different customer needs and suit diverse production scenarios.

Laboratory Grade (5-50L): Features a tilting design with variable frequency speed control and timing functions, supporting small-batch formulation validation.

Pilot-Scale Grade (100-1000L): Equipped with a jacketed heating/cooling system for precise temperature control, suitable for mixing processes requiring heat-sensitive ingredients (such as collagen peptides).

Mass Production Grade (1000-5000L): Employs a biaxial, dual-ribbon structure, with a single-unit processing capacity of up to 3 tons/hour, supporting continuous production.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The Protein Powder Ribbon Stainless Steel Mixer, with its flexible mixing structure and customizable design, enables high-speed mixing of various forms of materials, including powders, granules, pastes, and liquids, with protein powder, meeting the production needs of different formulations and product categories.

Powdered Materials: This mix covers various functional powders and trace ingredients, such as vitamin powder, mineral powder, probiotic powder, and dietary fiber powder, which can be blended with protein powder to enhance the nutritional value of the product. It can also precisely process seasonings such as spice powder, chili powder, sugar powder, and salt, as well as additives such as preservatives, antioxidants, and colorings.

Granular Materials: This mix is compatible with various nut pieces, grain particles, and puffed particles, such as almond pieces, oat flakes, and nut powder. When mixed with protein powder, it can be used to develop high-fiber or high-protein snacks. It can also process puffed particles such as rice cracker pieces and cornflake pieces, providing material mixing support for the production of meal replacement powders and energy bars.

For paste/viscous materials: Suitable for viscous materials such as honey and syrup. When mixed with protein powder to create high-energy foods, it allows for proper stirring to control viscosity and prevent clumping. It also supports the addition of jams/purses such as blueberry jam and apple puree.

For liquid additives: When used with a spray system, it can evenly add oily liquids such as fish oil and flaxseed oil, allowing the liquid to coat the protein powder particles and improve product solubility. For liquid ingredients such as flavorings and fragrances, spraying avoids evaporation loss caused by direct contact with high temperatures, ensuring stable and long-lasting flavor in the protein powder product.

The mixing time for a single batch with the Protein Powder Ribbon Stainless Steel Mixer is typically between 5-30 minutes, depending on the properties of the material, equipment specifications, and process requirements. For example, a 2000L machine processing brown rice protein powder takes approximately 8-20 minutes; smaller machines may only require 2-3 minutes, while larger machines may require 20-25 minutes.

As a manufacturer, we serve clients across various industries and types, solving pain points such as additive dispersion, multi-material mixing, and large-scale production. Our Protein Powder Ribbon Stainless Steel Mixer has gained recognition from clients at all levels for its customization and high uniformity.

Whey Protein Powder Production: Solving the problem of uneven dispersion of trace additives. Previously, when using ordinary mixing equipment, uneven dispersion of trace additives such as B vitamins and probiotics was common, leading to large fluctuations in product nutritional analysis and a high rate of customer complaints. After introducing two 10m³ protein powder ribbon stainless steel mixers, the double-layer ribbon convection mixing structure controlled the coefficient of variation of mixing uniformity to within 2.5%, significantly improving additive dispersion. Simultaneously, the equipment uses 304 stainless steel and a silicone scraper design, reducing the residue rate to 0.3%, meeting food hygiene standards and reducing raw material loss.

Startup Meal Replacement Powder: This product utilizes multi-form material mixing and small-batch customization, featuring a composite formula of "protein powder + grain particles + fruit puree." Frequent formula changes and small batch sizes are required. A 5m³ customizable ribbon mixer was purchased. This equipment supports variable frequency speed control, gently mixing granular materials such as oatmeal and chia seeds to prevent breakage, while also evenly mixing viscous ingredients like apple puree and honey through a spray system. Furthermore, the customized side discharge port seamlessly integrates with the packaging machine, reducing material transfer steps.

Large-Scale Nutritional Foods: To meet the needs of large-scale production and automation, four 20m³ protein powder ribbon mixers made of stainless steel were introduced to form an automated production line. The equipment has standardized interfaces for integration with the front-end spray dryer and the back-end automatic screening and packaging system, achieving full automation from raw material input to finished product packaging. The equipment is equipped with material level protection and overload protection devices to ensure stable operation at a daily capacity of 150 tons; the 316L stainless steel construction meets the corrosion resistance requirements of its deep-sea fish protein powder.

The price of a Protein Powder Ribbon Stainless Steel Mixer varies considerably depending on the equipment specifications, materials, and brand. DaHan Machinery's protein powder ribbon mixers start at $1500, suitable for laboratory or small-scale production. Medium and large-scale equipment, using thickened stainless steel, optimized ribbon structure, and equipped with a variable frequency speed control system, are more expensive and suitable for industrial continuous production. Customized equipment, such as those equipped with jacket heating, vacuum feeding, or automatic cleaning modules, requires a detailed price quote based on your specific needs.

Dahan Machinery is a professional manufacturer of Protein Powder Ribbon Stainless Steel Mixers. Their products utilize a double-layer ribbon structure, employing a convection design where the outer layer gathers inward and the inner layer conveys outward, achieving three-dimensional mixing of materials and ensuring a protein powder uniformity of over 99%. The equipment is made of 304/316L stainless steel, supports GMP standard customization, and is suitable for the stringent requirements of the food and health product industries. The inlet and outlet positions can be modified to suit the customer's production site, and the addition of rollers allows for easy return of the equipment to a designated location after use.

With its scientific mixing principles, reliable material quality, and flexible adaptability, the Protein Powder Ribbon Stainless Steel Mixer has become a core piece of equipment in modern protein powder production. As the health food industry continues to demand higher product quality and production efficiency, this equipment will continue to be optimized and upgraded to provide safer and more nutritious protein powder products for consumers worldwide.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.