We specialize in the production of various types of Ribbon Mixer , and the basic model of Ribbon blender price is as low as $1,250! We provide a full range of products from laboratory small machines to industrial large machines, covering single-axis/double-axis, carbon steel/stainless steel and other configurations. The specific price is flexibly adjusted according to capacity, material and function. All equipment has passed strict quality inspection and supports customized services. You can contact us at any time to get a detailed price list!

The factors affecting the price of the mixer itself include capacity, which ranges from a few liters to tens of cubic meters, with significant differences; the structure is single-axis or double-axis, and whether it has a ribbon.

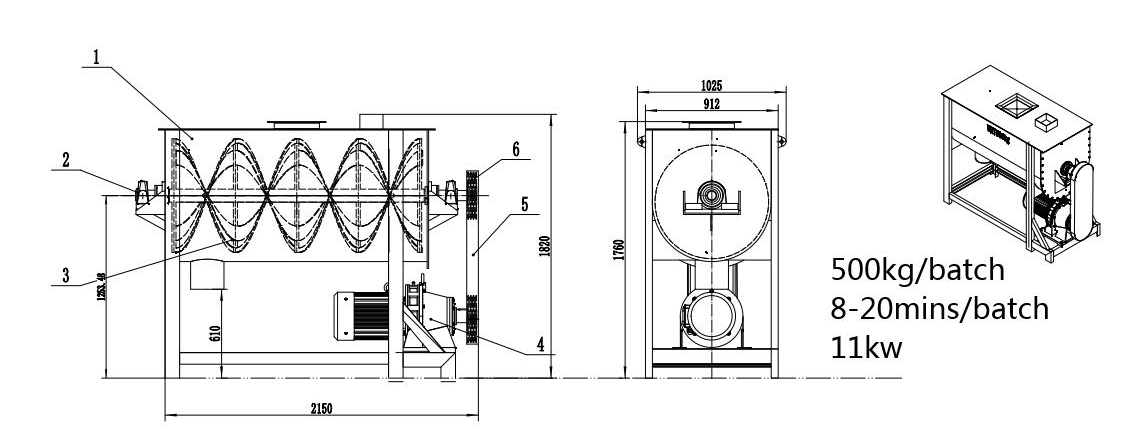

Capacity: The capacity of the ribbon blender ranges from dozens of liters for laboratory use to tens of cubic meters for industrial production. The small structure is relatively simple and the price is usually relatively low, while the large 10-30 cubic meter blender is used for large-scale production, such as the material mixing link of large chemical companies, and its price may be as high as tens of thousands of yuan.

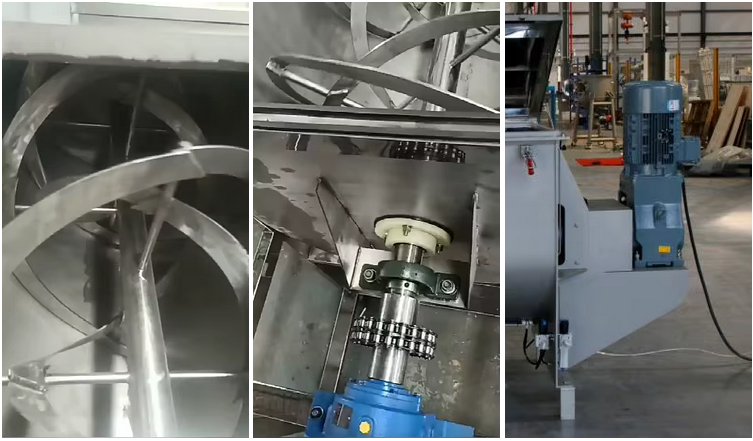

Structural design: The single-ribbon structure is relatively simple and the cost is relatively low. It is suitable for scenes with low material mixing requirements. Its price is generally lower than that of double-ribbon or multi-layer ribbon mixers at the same capacity. The double-ribbon mixer enhances the convection and shearing effect of the material through the coordinated work of the inner and outer ribbons, and the mixing efficiency and uniformity are higher. The price is also increased accordingly, usually 20% - 50% more expensive than the single-ribbon mixer.

Material selection: The material in contact with the material has a significant impact on the price. Ordinary carbon steel material has low cost and is affordable. It is suitable for mixing ordinary materials that do not require pollution and corrosion, such as sand and gravel mixing in the construction industry. A small carbon steel ribbon mixer may only cost $1,450. 304 stainless steel has a certain degree of corrosion resistance and is widely used. The price is higher than carbon steel, generally 1.5 - 2.5 times the price of carbon steel.

Adding some additional functions to an ordinary mixer will increase the cost of the entire machine. The detailed information is as follows.

Temperature control function: Heating/cooling jacket increases equipment cost. For processes that require precise control of material mixing temperature, such as chemical reactions and certain links in food processing, the ribbon mixer can be equipped with a heating/cooling jacket. Steam jackets are suitable for medium and low temperature heating and are relatively inexpensive; thermal oil jackets can achieve high temperature heating and are more expensive; cold water/chilled water jackets are used for rapid cooling to prevent material denaturation. The price of a mixer equipped with a temperature control jacket will increase by 10% - 50% depending on the jacket type and accuracy requirements.

Vacuum function: When handling materials that are easily oxidized, afraid of moisture or contain volatile components, such as medical ointments, battery slurries, etc., vacuum ribbon mixers become the first choice. The vacuum system includes vacuum pumps, vacuum buffer tanks, vacuum air-breaking devices, etc. The configuration of these components greatly increases the cost of the equipment.

Explosion-proof function: In the mixing scenarios of flammable and explosive materials, such as solvent-based coatings, lithium battery material production, etc., the ribbon mixer must have an explosion-proof function. This includes the use of explosion-proof motors and electrical appliances, as well as nitrogen protection systems, static elimination devices, explosion relief discs/safety valves, etc. Explosion-proof configurations greatly increase the cost of equipment. The price of a ribbon mixer with explosion-proof function is generally 2-3 times that of an ordinary model.

We provide one-stop customization services for the full volume range of 0.1L-20m³, with prices as low as $1,250! Covering small laboratory models to large industrial equipment. With high cost-effectiveness and professional customization services, we are committed to providing customers with the best mixing solutions.

Clarify material properties: Based on physical properties, single shaft is selected for low viscosity, and double shaft is required for high viscosity; light powders are dustproof and heavy particles are equipped with strong motors; adhesive materials are equipped with scrapers. In terms of chemical properties, 316L stainless steel is used for corrosive materials, explosion-proof and nitrogen protection is required for flammable and explosive materials, and GMP standards are required for food and medicine.

Determine process requirements: standard single shaft is used for simple mixing, double shaft or multi-layer ribbon is selected for high uniformity, and vacuum models are required for degassing and degassing. In terms of production scale, the 5-100L manual type is used for small trials, the 0.1-2m³ semi-automatic type is used for pilot trials, and the 2-20m³ fully automatic equipment is used for mass production. The corresponding jacket and PLC module can be added for temperature control needs.

Choose the type of equipment: Single-axis is suitable for conventional mixing, with simple structure and low cost; double-axis processes high-viscosity materials and has strong shear force; vacuum type prevents oxidation and degassing, and the price is higher; vertical type is suitable for space-constrained scenes, but the capacity is small and needs to be selected on demand.

Choose us to customize 0.1L-20m³ equipment in one stop, with a variety of configurations to choose from, energy saving and power saving of 15-30%, and non-standard solutions can also be provided.

Leading technical strength: Deeply engaged in the research and development of mixing equipment, mastering the core ribbon optimization technology, and owning a number of patents, covering special ribbon structures, energy-saving transmission systems, etc.

One-stop customization capability: The equipment covers 0.1L laboratory models to 20m³ industrial giants, providing more than 100 configuration combinations, including 304/316L/carbon steel/plastic lining and other materials, vacuum, explosion-proof, CIP, temperature control and other functions, frequency conversion, explosion-proof, hydraulic and other drive methods. As a non-standard design manufacturer, it has successfully delivered aerospace-grade composite mixers, nanomaterials special anti-pollution models, etc.

Visible cost optimization: The equipment adopts energy-saving design, saving 15-30% more electricity than its peers; SKF bearings, Siemens motors and other high-quality components are selected, the life span is doubled, and the failure rate is reduced by 60%. At the same time, value-added services are also provided to effectively reduce costs for customers.

The price of ribbon mixers is affected by a variety of factors. When purchasing, it is necessary to comprehensively evaluate your own needs, weigh the relationship between equipment performance, functional configuration, brand service and price, so as to choose the most cost-effective ribbon mixer that best suits the production needs of the enterprise and maximizes production benefits.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.