Stainless Steel Ribbon Mixer for Cat Food is a device designed for mixing cat food, specifically for cat food production. Constructed from food-grade 304/316L stainless steel, it features a single/double ribbon mixing structure and a mixing capacity of 50L-10m³. This allows for flexible matching to different production capacities, from small-scale laboratory trials to large-scale production. Mixing time is only 5-12 minutes, achieving precise homogenization of multiple ingredients such as grain powder, meat meal, vitamins, and minerals, effectively solving the mixing challenges of complex cat food formulas and ingredients with varying proportions of gravity.

To address the diverse needs of cat food production, the Stainless Steel Ribbon Mixer for Cat Food supports multi-dimensional customization and functional expansion. With a capacity of 50L-10m³, the mixing speed can be adjusted according to the characteristics of the ingredients. For example, the speed can be reduced when mixing easily clumping meat meal and increased when mixing lightweight grain powder to optimize the mixing effect. In addition, a spraying device can be added as needed for adding liquid ingredients such as oils and meat juices, achieving precise solid-liquid mixing and improving the flavor and binding properties of the cat food. Adding a weighing module enables automatic raw material measurement, reducing human error and improving production efficiency. The equipment's inlet can be connected to an automatic feeding system, and the outlet is equipped with a butterfly valve or a rotary valve for continuous production.

Our factory produces two main types of Stainless Steel Ribbon Mixers for Cat Food: single-ribbon and double-ribbon. Both are made of food-grade 304/316L stainless steel and are suitable for mixing powders, granules, and solids/liquids in cat food production. The appropriate model can be selected based on production capacity and raw material characteristics.

Single-ribbon cat food stainless steel ribbon mixer: Features a single-layer spiral blade design, paired with a horizontal U-shaped trough and a single stirring shaft. The small gap between the blades and the inner wall of the trough results in a simple, compact structure with a moderate footprint, suitable for start-up cat food workshops and small-scale laboratory trials. It can handle free-flowing grain powders and single-protein ingredients.

Double-ribbon cat food stainless steel ribbon mixer: Employs a double-layer reverse spiral design. The inner layer pushes the material forward, while the outer layer pushes it back in a closed loop, resulting in a stronger stirring shaft and blades. Through a combination of axial convection and radial shearing motion, the material tumbles and intertwines frequently, quickly breaking up stratification and agglomeration. Mixing time is only 5-10 minutes. It supports the addition of a spray device for solid-liquid mixing and is suitable for large-scale production in medium to large-sized cat food processing plants.

The Stainless Steel Ribbon Mixer for Cat Food uses stainless steel as its base material, with a sealed structure that prevents contamination and facilitates cleaning. Single/double ribbon design adapts to different formulas, low energy consumption and simple maintenance, making it the preferred equipment for safe pet food production.

Food-grade safety guarantee: All parts in contact with materials are made of 304/316L stainless steel, with mirror-polished inner and outer walls, corrosion-resistant, rust-proof, and easy to clean, meeting pet food hygiene standards.

Mixing efficiency: Single mixing time is only 5-10 minutes, with a mixing uniformity of over 99%, far exceeding traditional mixing equipment.

Energy consumption control: Power consumption per ton of material mixed is less than 1.5 kWh, with significant energy savings.

High adaptability: Volume ranges from 50L to 10m³, supports variable frequency speed control, and can mix powders, granules, and solid-liquid materials with added oils, meeting diverse needs from laboratory pilot projects to large-scale production.

Customizable Expansion: Features such as spraying, weighing, and automatic feeding can be added as needed, adapting to the production of different cat food categories, including dry and semi-wet food, flexibly matching personalized formula requirements.

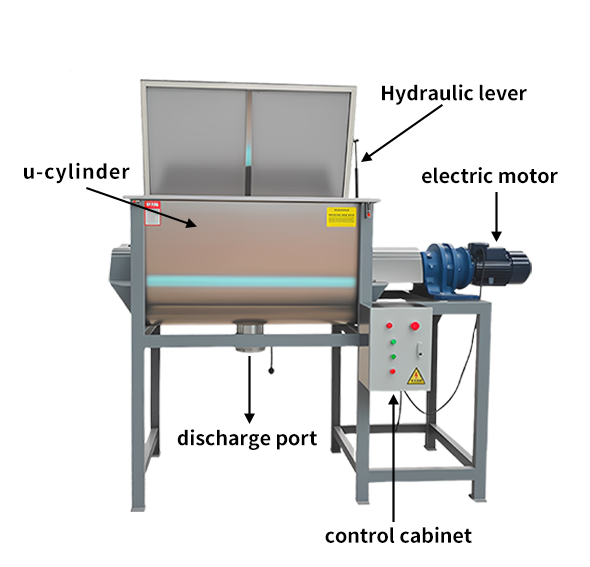

The Stainless Steel Ribbon Mixer for Cat Food consists of a horizontal U-shaped tank, single/double ribbon mixing components, a transmission system, and a sealing device. The overall design is compact and durable, ensuring rapid mixing and hygienic safety.

Mixing Tank: Utilizing a horizontal U-shaped design, made of stainless steel with mirror-polished inner and outer walls, eliminating unsanitary corners, resisting corrosion and rust, and reducing material residue. The thickened tank design enhances structural stability.

Ribbon Mixing Component: The core working component, available in single/double ribbon versions. The blades are made of high-strength stainless steel in a single piece, with minimal gap between the blade and the inner wall of the tank.

Transmission System: Composed of a motor, reducer, and coupling. A variable frequency speed control motor is available, and the reducer uses a hardened gear surface type, ensuring high transmission efficiency and low noise.

Sealing Device: Food-grade silicone sealing strips are installed at the inlet, outlet, and both ends of the mixing shaft. A dust cover is provided at the inlet, and a butterfly valve/rotary valve is used at the outlet to achieve fully enclosed mixing, preventing dust leakage and external contamination.

Support and Auxiliary Structure: A welded carbon steel frame is used, with leveling feet at the bottom for easy installation and fixation. Spraying devices, weighing modules, and maintenance doors can be added as needed to meet customized production requirements.

The Stainless Steel Ribbon Mixer for Cat Food achieves mixing through double or triple ribbon mixing. Its core structure consists of a U-shaped container and forward and reverse rotating ribbon mixing blades. The outer ribbon gathers material from both sides to the center, while the inner ribbon transports it in the opposite direction to both sides, forming a three-dimensional convection circulation. The rotation of the ribbon generates shearing and diffusion effects, causing the material to continuously tumble and move axially within the cylinder, ensuring uniform mixing of powders, granules, or viscous materials.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

The Stainless Steel Ribbon Mixer for Cat Food is widely used in all aspects of the pet food industry. It can process multi-ingredient raw materials such as grain powder, meat meal, and trace additives. It is a core piece of equipment for homogenizing and mixing cat food nutrients under food-grade safety standards.

Raw Material Premixing: In the early stages of cat food production, meat powder, grains, vitamins, minerals, etc., need to be precisely mixed according to the formula.

Additive Fusion: For formulas requiring the addition of liquid ingredients, the spray-type ribbon mixer can achieve uniform adhesion of liquid raw materials through top atomizing nozzles, preventing excessively high local concentrations.

Special Process Support: For the production of low-temperature baked cat food or prescription food, the mixer can be linked with a freeze-drying system to control the material temperature during the mixing process and retain heat-sensitive nutrients.

The Stainless Steel Ribbon Mixer for Cat Food can be directly integrated with core equipment such as screening, feeding, and packaging machines. It can also be combined with auxiliary equipment such as crushing, hopper/weighing, and puffing/drying machines to form a complete production line from raw material pretreatment to finished product packaging.

Screening Machine + Stainless Steel Ribbon Mixer for Cat Food: Before entering the mixer, the raw materials are pretreated by a vibrating screen or rotary screen to remove lumps, impurities, and large particles, ensuring that the material entering the mixer has a uniform particle size and is free of impurities. This combination avoids lumpy raw materials affecting mixing uniformity, reduces wear on the mixer's internal blades, and extends equipment life. It is especially suitable for processing cat food raw materials containing trace additives and prone to agglomeration.

Feeder + Stainless Steel Ribbon Mixer for Cat Food: Using a screw feeder, vacuum feeder, or bucket elevator, raw materials such as corn flour, meat meal, and vitamin premixes can be directly transported from the storage silo to the mixer's inlet. The entire process is sealed to prevent dust leakage and raw material contamination, meeting pet food hygiene standards.

Stainless Steel Ribbon Mixer for Cat Food + Packaging Machine: The linkage between the mixer and packaging machine forms a closed-loop mixing-packaging process for cat food production. The uniformly mixed material is directly connected to the quantitative packaging machine through the outlet. The packaging machine's weighing, metering, and sealing functions quickly complete the packaging of finished products such as bags and cans. This combination reduces secondary contamination and residues during material transfer, ensuring that the nutritional uniformity of the finished cat food is not affected.

Our Stainless Steel Ribbon Mixer for Cat Food has served over 200 pet food companies, covering startups, medium-sized factories, and large-scale production facilities. From small-batch trial production of 50L to large-scale batch mixing of 5m³, adaptable to diverse formulas such as grain-free and fresh meat cat food.

Startup cat food workshop: Focusing on the production of natural grain-free cat food, initially focusing on small-batch trial production, using a 50L double-ribbon stainless steel cat food mixer. The workshop's raw materials include chicken meal, fish meal, oat flour, and various vitamin and trace additives, requiring the solution to the mixing challenge of components with large differences in proportion. The equipment uses 304 stainless steel and a double-layer reverse ribbon design to ensure nutritional balance in each batch of cat food, and its polished internal and external structure is easy to clean, meeting the needs of rapid switching between small-batch, multi-formula production.

Medium-sized cat food processing plant: A medium-sized enterprise focusing on fresh meat-filled cat food, facing problems of uneven oil addition and poor palatability of the finished product, introduced a 1000L double-ribbon mixer with spray function. The equipment utilizes a combined axial convection and radial shear mixing system, along with a precision spraying system, to evenly spray liquid ingredients such as chicken broth and fish oil into the powder mixture. The mixing time is only 8 minutes, and the solid-liquid mixing uniformity far surpasses previous equipment.

For large-scale cat food production: For batch mixing of more than ten ingredients including grain powder, meat meal, and minerals, a 5m³ double-ribbon stainless steel cat food mixer is used. The equipment is made of 316L stainless steel, suitable for mixing high-oil and high-moisture ingredients, and can precisely distribute trace additives evenly in complex formulas.

The price of a Stainless Steel Ribbon Mixer for Cat Food varies depending on the model, specifications, and configuration. Our factory's prices start from $1000. Prices vary depending on the model. Additionally, some customers require heating/cooling functions and customized inlet/outlet positions and directions, which will increase the price. A detailed quote requires a combination of your production needs and site conditions to recommend a suitable model. If needed, please provide your detailed requirements, and we will prepare a comprehensive quotation.

The Stainless Steel Ribbon Mixer for Cat Food, with its uniform mixing capabilities, corrosion-resistant material properties, and flexible process adaptability, has become an indispensable core piece of equipment in pet food production. It not only helps companies improve product quality stability but also provides solid technical support for the industry's large-scale and refined development through energy saving, consumption reduction, and automation upgrades.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.