Industrial Powder Ribbon Mixer with its unique three-dimensional convection mixing principle and modular design, is an ideal choice for solving high-precision, high-volume mixing challenges. This equipment uses a double-layer counter-rotating spiral belt to drive powder in a U-shaped tank, creating a combined radial and axial motion. This quickly eliminates stratification of materials with particle size differences exceeding 10 times, achieving a mixing uniformity of over 99.5%. Furthermore, we support non-standard customization, allowing us to tailor production to your existing equipment and ensure the smooth operation of the entire production line.

The Industrial Powder Ribbon Mixer achieves 99.5% mixing uniformity within 5 minutes with its double-layer spiral belt three-dimensional convection design, compatible with materials with particle size differences of up to 10 times. The U-shaped tank features a fully sealed enclosure. Its modular structure supports temperature control, forward and reverse rotation, and continuous operation.

Continuous production: Enables 24-hour uninterrupted mixing, with throughput ranging from several tons to tens of tons per hour, increasing production efficiency by 30%-50% compared to batch processing equipment. Uniform Mixing: By optimizing the ratio of belt speed to paddle rotation speed, the mixing uniformity can reach over 95%, and the residence time of materials in the chamber is controllable, ensuring consistent mixing quality for each batch.

Wide Compatibility: It can handle various industrial powders with particle sizes of 50-500 mesh and specific gravities of 0.3-2.0 g/cm³, including dry powder, slightly wet powder, and light-density powders. The machine body is made of thickened steel with a wear-resistant coating, ensuring a service life of 8-10 years.

Supports Automated Integration: It can seamlessly connect with front-end feeding and back-end packaging equipment to achieve fully automated production, significantly reducing labor costs.

The core of the Industrial Powder Ribbon Mixer lies in its double-layer counter-rotating spiral belt design. The main body of the equipment is a U-shaped trough, inside which are installed two layers of spiral belts rotating in opposite directions: the outer spiral rotates to the left, pushing the material towards the center of the trough; the inner spiral rotates to the right, dispersing the material to both ends. This convection circulation mechanism causes materials to move simultaneously radially and axially, forming a three-dimensional turbulent field. This ensures that even materials with particle size differences exceeding 10 times can achieve a mixing uniformity of over 99.5% within 5-15 minutes.

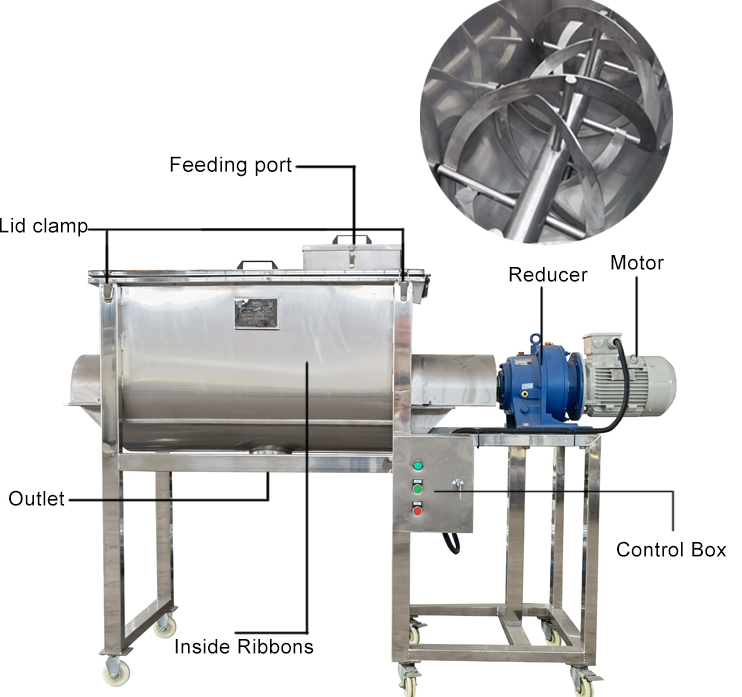

An Industrial Powder Ribbon Mixer mainly consists of a U-shaped shell, ribbon agitator blades, transmission components, and sealing structures. Its structural design and functional characteristics are closely centered around high-speed mixing, uniform dispersion, and adaptability to complex working conditions.

Mixing Container: Generally a horizontal structure, commonly U-shaped containers and cylindrical cylinders. The material can be selected according to the material characteristics; for example, carbon steel is used for non-corrosive materials, while stainless steel 304 or 316L is used for food, pharmaceutical, or corrosive materials.

Ribbon Agitator Blades: The core component of the mixer, usually made in double or triple layers. The outer ribbon gathers the material from both sides to the center, while the inner ribbon transports the material from the center to both sides, forming convection mixing.

Transmission components: These include a motor, reducer, gears, chains, or couplings. The motor provides power, the reducer lowers the speed and increases the torque, and then the power is transmitted to the main shaft via gears and chains, driving the ribbon mixing blades to rotate.

Support structure: This supports the overall weight of the mixer and is typically composed of a bracket or base, ensuring the stability of the equipment during operation.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

As a core piece of equipment for mixing powder materials, the Industrial Powder Ribbon Mixer has applications covering various fields. Utilizing three-dimensional convection mixing technology, it achieves a uniformity of over 99.5%, helping various industries improve product quality and production efficiency.

Building materials industry: Mixing cement, mortar, putty powder, tile adhesive, insulation materials, etc., meeting the requirements for uniform material proportions in construction.

Chemical industry: Mixing pigments, dyes, plastic granules, rubber additives, chemical powder additives, etc., ensuring the consistency of components in chemical product production.

Food Industry: Used for mixing flour, milk powder, seasonings, food additives, and grain powders, meeting hygiene and mixing precision standards for food processing.

Feed Industry: Used for mixing basic powders and nutritional additives (such as vitamins and minerals) in livestock and poultry feed and aquatic feed, ensuring balanced nutrition.

Belt mixers achieve three-dimensional convection through a double-layer spiral belt, achieving a mixing uniformity of over 99.5%, making them suitable for new energy and pharmaceutical fields. Paddle mixers use high-speed impellers to create gravity-free mixing, completing a single batch mixing in 90 seconds, making them more suitable for low-viscosity materials in food and chemical industries.

Belt mixers: The core is a double/triple-layer spiral ribbon blade. The outer layer gathers material towards the center, while the inner layer conveys material to both sides, creating forced convection mixing with vigorous overall material agitation.

Paddle mixers: The core is a straight or inclined paddle. The rotating paddles propel the material in a circular motion, relying on the material's own diffusion for mixing, resulting in weaker convection.

Mixing efficiency: Belt mixers are highly efficient, achieving uniformity in a short time (typically 5-15 minutes); paddle mixers are less efficient and require longer times (15-30 minutes or more). Mixing Uniformity: Belt mixers offer high uniformity, suitable for high-precision proportioning requirements; paddle mixers offer moderate uniformity, suitable for applications with lower uniformity requirements.

Material Compatibility: Belt mixers can handle powders and fine particles, and are also compatible with small amounts of liquid addition (with a spray device), tolerating slightly agglomerated materials; paddle mixers are more suitable for coarse particles and low-viscosity materials, but have poor mixing effects on fine powders or easily agglomerated materials.

The Industrial Powder Ribbon Mixer redefines mixing efficiency with its innovative spiral ribbon structure. A double-layered, counter-rotating spiral ribbon, combined with a U-shaped tank design, achieves three-dimensional convection shear mixing, boosting uniformity to 99.8%.

Upgraded Sealing System: Utilizing a combined gas-tight + packing seal structure, along with a fully enclosed cylinder cover design, it can withstand positive or negative pressure environments of 0.1 MPa, meeting GMP certification requirements in the pharmaceutical industry. Real-world testing data from a vaccine manufacturer shows that this design reduces dust leakage rate to below 0.02 mg/m³.

Integrated Temperature Control Technology: The tank jacket supports steam heating (up to 200℃) and coolant cooling (down to -40℃). Combined with a temperature sensor and PID control system, it achieves precise temperature control within ±1℃. In epoxy resin curing agent production, this function shortens reaction time by 40% and controls product color difference ΔE values to within 1.5.

Intelligent discharge control: The pneumatic flap valve is linked to a gravity sensor, automatically closing when the remaining material in the tank is detected to be below 5%, preventing batch-to-batch cross-contamination caused by residue. After implementation, a food additive company saw its product microbiological compliance rate increase to 99.98%.

Energy Consumption and Cost: Belt mixers have high power consumption and higher energy costs, resulting in higher equipment purchase costs; paddle mixers have lower power consumption and lower energy costs, making them more economical in terms of purchase and maintenance.

When selecting an Industrial Powder Ribbon Mixer, it's crucial to comprehensively consider factors such as throughput, material properties, mixing precision, and equipment functionality. A balance between performance and cost must be struck based on process requirements to avoid over-configuration or insufficient functionality.

Capacity Matching: Select the appropriate model based on the hourly throughput to avoid overcapacity or undercapacity.

Material Adaptability: Adjust the belt speed and paddle structure according to the powder's particle size, moisture content, specific gravity, and other characteristics. For example, when handling easily agglomerated powders, a dispersing device should be added.

Material Selection: Carbon steel is suitable for general industrial applications, while corrosive powders require upgrading to a 304/316L stainless steel chamber.

Function Customization: Add modules such as temperature control, dust removal, and magnetic separation according to production needs to improve production safety and convenience. Finally, verify that the equipment meets industry standards.

The price of an Industrial Powder Ribbon Mixer varies considerably depending on the model, configuration, and brand. DaHan Machinery's basic belt mixers typically start at around 1200 RMB. These models are mostly suitable for small-scale production or laboratory settings, providing basic mixing functions, but with relatively limited capacity and mixing uniformity. For models requiring higher capacity or better mixing results, such as those supporting temperature control, forward/reverse rotation, or large-capacity designs, the price will rise to tens of thousands of RMB or even higher. A specific price will be determined based on your production needs to recommend the most suitable model and provide the optimal price list.

The Industrial Powder Ribbon Mixer is a continuous mixing equipment designed specifically for industrial-scale powder mixing. With its innovative integrated belt conveyor and mixing structure, it achieves continuous feeding, uniform mixing, and stable discharge of powder materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.